Balancing lead time and flexibility is crucial in small-batch customization. You want to meet customer demands without compromising on quality. When you manage these aspects effectively, you enhance customer satisfaction and boost your business. However, challenges arise, such as managing customer expectations and handling inventory. You may also face difficulties in securing skilled workers and navigating a complex supply chain. By addressing these challenges, you position your business for success in delivering custom solutions.

Key Takeaways

Talk to clients to understand their needs. Use tools like product configurators. This helps build loyalty and makes customers happy.

Create strong relationships with suppliers for better material sourcing. Trust and clear communication help reduce mistakes and improve efficiency.

Use agile production methods to be more flexible and cut lead times. Techniques like SMED and Kanban can greatly boost productivity.

Set realistic timelines for production by looking at tasks and resources. This helps manage expectations and improves overall efficiency.

Watch production processes in real-time to quickly adjust to changes. Using advanced technologies can make things more efficient and reduce downtime.

Client Needs in Customization

Identifying Specific Requirements

Knowing what clients need is very important for small batch customization. When you understand what your clients want, you can change your products to meet their needs. Here are some good ways to find out what clients want:

Use a product configurator. This tool lets customers help create value, which builds loyalty.

Use the configurator to quickly make a bill of materials (BOM) from customer input. This makes things faster and cuts lead times.

Group BOMs into families with different options. This makes paperwork easier and helps manage orders better.

Gather data from custom orders to find popular choices. Making these standard can give you an advantage.

Provide special products to keep customers coming back. A great buying experience makes clients return.

Effective Client Communication

Good communication is key to understanding client needs. You want to make sure you and your clients agree during the customization process. Here are some best practices to improve your communication:

Best Practice | Description |

|---|---|

Centralized Communication | Manage content without needing IT, so updates are quick across channels. |

Standardized Processes | Guide your team on how to communicate, including using automated messages. |

Multi-channel Delivery | Keep messages the same across email, SMS, and social media. |

Personalization | Create customer profiles and study preferences for better communication. |

Documentation | Keep clear records of decisions and next steps to stay aligned with clients. |

Also, prepare several approved options for clients when problems come up. Write down the decision path right after a client picks a choice. This method meets client needs and builds trust and openness.

By focusing on understanding and communicating well with your clients, you can make the customization process smoother. This will improve satisfaction and loyalty.

Efficient Material Sourcing

Getting materials efficiently is very important for small-batch production. When you get materials well, you can lower costs and improve quality. This helps you meet customer needs better. Building strong relationships with suppliers can make your sourcing better.

Building Supplier Relationships

To create good partnerships with your suppliers, try these strategies:

Negotiate Fairly

Build Trust with Your Manufacturer

Keep Communication Professional

Check In Regularly

Be Clear with Specifications

Ask for Precision Without Micromanaging

Encourage a Team Spirit

Respect Cultural Differences

Share Your Vision and Goals

Promote Face-to-Face Meetings

Show Appreciation

These steps help you build a reliable network. A good relationship leads to better communication and fewer mistakes. Suppliers will be more willing to help you when they trust you.

Just-In-Time Inventory

Just-in-time (JIT) inventory can greatly cut lead time in small-batch production. By getting materials only when you need them, you save on storage costs and waste. This method lets you react quickly to changes in demand.

Company | Lead Time Reduction | Productivity Increase | New Model Introduction Speed |

|---|---|---|---|

Nike | 20% | 30% faster |

However, JIT has risks. If a supplier does not deliver on time, your whole production can stop. To reduce these risks, you should:

Invest in technology

Use continuous improvement practices

By focusing on these areas, you can enjoy the benefits of JIT while reducing possible problems. Efficient material sourcing, along with good supplier relationships and JIT methods, can lead to smoother operations and happier customers.

Flexible Manufacturing Techniques

Flexible manufacturing is very important for changing market needs. It helps you respond quickly to what customers want while keeping quality high. By using flexible manufacturing methods, you can improve how you produce items and shorten lead times. This way, you work better and stay competitive in a fast-moving market.

Agile Production Methods

Agile production methods are key to flexible manufacturing. They help you make processes smoother and cut down on waste. Here are some popular agile methods used in small-batch manufacturing:

Description | |

|---|---|

Single-Minute Exchange of Die (SMED) | Aims to cut changeover time to under 10 minutes, boosting productivity and reducing downtime. |

Cellular Layouts | Arranges the facility to save energy and time, speeding up production cycles. |

Kanban Board | Shows a visual workflow, helping to spot problems and adjust plans. |

Standard Work + 5S | Sets standard processes and organizes work areas to increase productivity and lower mistakes. |

Daily Standup Meeting | Encourages daily talks among team members to focus on priorities and solve issues. |

Finite Capacity Scheduling | Improves production schedules based on real resources, making work more efficient. |

Visual Management (Andon) | Provides real-time updates on production status, allowing quick fixes to problems. |

Manufacturing Execution System (MES) | Monitors production data in real-time and ensures transparency, allowing fast changes in operations. |

Enterprise Resource Planner (ERP) | Combines data about orders and inventory, helping with planning and cutting material waste. |

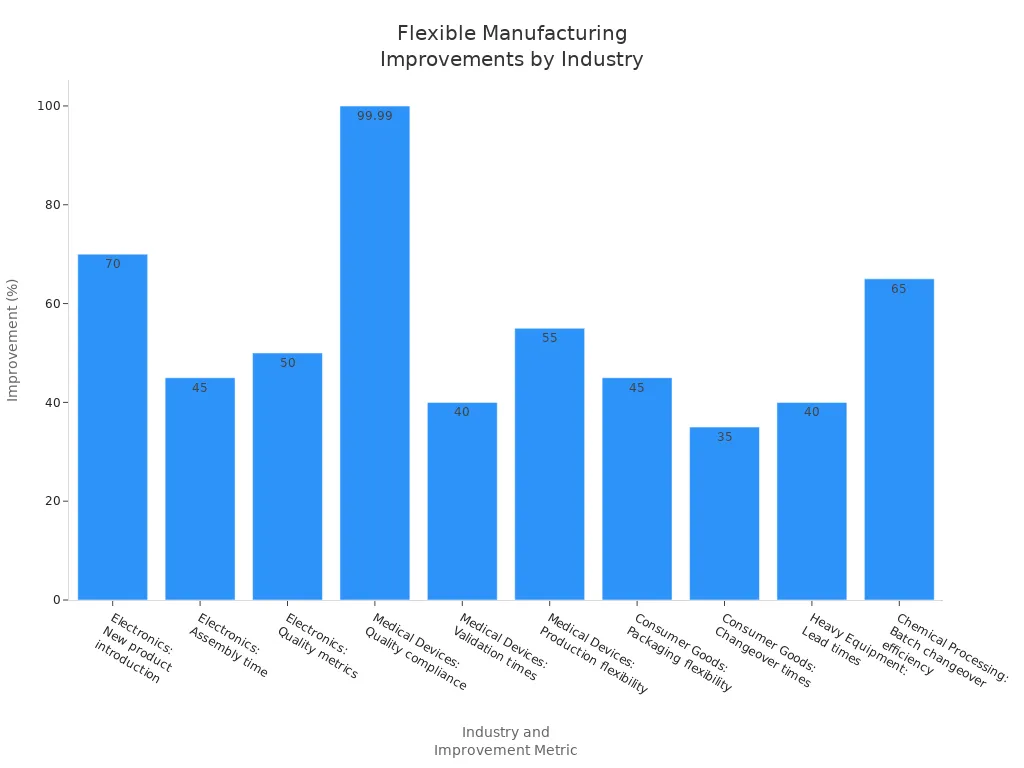

These methods lead to big improvements in production flexibility and shorter lead times. For example, industries that use flexible manufacturing see great results:

Industry | Improvement Metrics |

|---|---|

Electronics | 70% faster new product introduction |

45% less assembly time | |

50% better quality metrics | |

Medical Devices | 99.99% quality compliance rates |

40% less validation time | |

55% better production flexibility | |

Consumer Goods | ~45% better packaging flexibility |

~35% less changeover time | |

Heavy Equipment | ~40% less manufacturing lead times |

Chemical Processing | ~65% better batch changeover efficiency |

Kingham’s Custom Solutions

At Kingham, we use flexible manufacturing to provide custom solutions that fit your needs. Our method combines new technology with a focus on quality. With over 15 years of experience, we aim for innovation and constant improvement.

Our manufacturing facility has advanced CNC machines and automated assembly lines. This setup helps us make high-quality parts efficiently. We also use new technologies like robotics and cloud-based Manufacturing Execution Systems (MES) to boost our production skills.

By offering OEM and ODM services, we create tailored solutions that match your brand’s needs. Our team works closely with you during the development process, making sure every detail meets your expectations. This focus on customization makes us stand out in the industry.

Quality Control in Customization

Keeping quality high in small-batch customization is very important. When you focus on quality, you lower defects and improve performance. This focus makes your customers happy and builds your brand’s reputation. To set good quality standards, think about these key practices:

Strict quality control steps lower defects and boost performance.

Getting ISO 9001 certification helps you create strong quality standards.

Ongoing improvement practices are key for keeping high-quality production.

By using these standards, you build a strong base for your customization work.

Continuous Improvement Practices

Ongoing improvement is vital for keeping your quality standards up. You can use several successful methods to make your processes better:

Kaizen Method: This method focuses on small, steady changes. For example, Command Medical Products improved their process efficiency by 50% by cutting batching cycles and speeding up drying times.

Lean Six Sigma: This method aims to reduce errors. MEDRAD cut record errors by 26% by standardizing processes and using technology.

Employee Engagement: Working with your team can lead to big improvements. Lauras International saw efficiency gains of 10% to 117% across many production lines through teamwork.

Besides these methods, think about improving workflows to remove bottlenecks. Making processes smoother boosts productivity and cuts costs. Using real-time data helps you spot problems quickly, allowing for focused solutions. Regular checks of your manufacturing processes keep you competitive and ensure you maintain high performance.

Key Aspect | Description |

|---|---|

Let you plot data from different processes for useful analysis. | |

Group Charts | Combine data from similar processes for SPC analysis even with little individual data. |

Benefits for Flexible Manufacturing | Help quality control in high-mix, low-volume settings, supporting mass customization. |

By focusing on these ongoing improvement practices, you can keep high-quality standards in your small-batch customization work. This dedication to quality not only improves your products but also builds trust with your customers.

Managing Lead Time & Flexibility

Setting Realistic Timelines

Making realistic timelines is very important for small-batch production. When you set achievable schedules, you lower stress and boost efficiency. Here are some good practices to help you create those timelines:

Job Analysis: First, understand the tasks and needs for each job. This helps you see how long each task will take.

Batch Formation: Group similar tasks together. This makes the workflow better and cuts setup times, making production smoother.

Resource Allocation: Make sure all needed resources are ready and used well. This means having the right materials and skilled workers available when you need them.

Sequencing: Plan the order of tasks carefully. This cuts delays and boosts efficiency, helping you keep production on track.

Scheduling: Make a detailed timeline for production based on your capacity and demand. This gives you a clear plan to follow.

Execution: Carry out your production plan while watching progress closely. Change things as needed to stay on schedule.

Continuous Improvement: Regularly check and improve your processes. This makes efficiency and effectiveness better over time.

By following these steps, you can manage your lead time & flexibility well. This ensures you meet customer needs without lowering quality.

Monitoring Production Processes

Watching your production processes is key for keeping flexibility. When you pay attention to operations, you can quickly adjust to changes and avoid problems. Here are some good ways to monitor:

Real-time Data Collection: Use sensors and smart machines to keep updating production data. This helps you find problems before they get worse.

Advanced Monitoring Systems: Use AI and machine learning tools to spot patterns and improve efficiency. These technologies help you make smart choices.

Digital Twins: Create models of your manufacturing processes. This lets you improve operations before making changes in real life.

Companies that use real-time monitoring have seen great results. For example, production efficiency can go up by 20%. Predictive maintenance can cut equipment breakdowns by 70%. Using monitoring systems can raise productivity by 6% to 30%.

By actively watching your production processes, you can improve your manufacturing lead time and flexibility. This approach helps you respond quickly to customer needs and keep high-quality standards.

In this blog, you learned some important ways to balance lead time and flexibility in small-batch customization. Here’s a quick summary:

Managing lead time well is important for balancing customization and delivery speed.

Talking clearly with customers about lead times helps set expectations and improves flexibility.

Being efficient is key; knowing different types of lead times can help you improve processes and respond better.

Using these strategies can really increase your customer satisfaction. Take a moment to look at your current practices. Think about using methods like process mapping or KPI monitoring to find areas to improve. By doing this, you can make your operations better and stay competitive in today’s market.

FAQ

What is small-batch customization?

Small-batch customization lets you change products to fit what customers want. This method makes customers happy by giving them special solutions while keeping high quality.

How can I ensure timely delivery?

To make sure deliveries are on time, focus on getting materials efficiently, using flexible operations, and talking clearly with suppliers. Setting realistic timelines helps manage expectations and improves delivery times.

Why is material quality and consistency important?

Material quality and consistency are very important for keeping products working well and lasting long. Good materials lead to better customization results and build customer trust in your brand.

What are agile operations?

Agile operations are flexible manufacturing methods that help you quickly adjust to changing market needs. This approach helps you lower lead times and boost overall production efficiency.

How can I improve my customization process?

You can make your customization process better by collecting customer feedback, using new technology, and regularly checking production. This helps you meet customer needs while keeping material quality and consistency high.