Yamaha Shock Absorbers

Manufacturer & OEM/Wholesale Suspension Supplier

- IATF 16949 & ISO 9001 certified processes ensure premium quality

- In-house CNC machining + anodizing control for consistency

- Built for "Commuter, Touring & Sport Programs"

- OEM/ODM support for new platform development

Built for Yamaha Distributors, Brands and Workshops

Distributors & Importers

Build a tiered Yamaha program with manageable SKUs. Start from top movers like NMAX, Aerox, and XMAX, then expand by tier depth and model-year coverage. Tiered price ladders (Good/Better/Best) available upon request.

Aftermarket & OEM Brands

Rebrand proven shock families or co-develop damping targets for commuter vs touring vs sport positioning.

We support prototype-to-production with clear validation communication.

Tuning Shops & Service Centers

Offer sellable upgrades with clear tuning logic for rider weight, load and road conditions.

We support after-sales workflow and spare parts guidance by email.

Ready to see the data?

Yamaha Scooter & Commuter Platform Overview

Platform

Typical Role

Key Markets

Main Suspension Opportunities

NMAX Series

High-volume urban commuter

SEA, LATAM

Two-up load support, daily bump compliance, stable recovery

XMAX Series

Maxi-scooter touring / premium commuting

Global

High-speed stability, long-ride consistency, luggage + passenger sag control

Aerox/NVX

Sport scooter / performance commuter

SEA / parts of EU

Braking dive control, corner stability, sharper response for tuning shops

Mio/Fazzio/Fino

Entry-level urban mobility

SEA

Comfort upgrade at value price, durability, visual options for retail

Y15ZR/Y16ZR/LC135/LC150

Underbone performance culture

SEA / emerging markets

Durability under aggressive use, rebound control for traction, consistent handling

YZF R15

Entry sportbike platform

SEA / LATAM

More precise chassis feedback, braking support, sport positioning

Product Segmentation for Yamaha Partners

We’ve segmented Yamaha suspension solutions into three key tiers: "Essential (Good)", "Performance (Better)", and "Premium (Best)". Distributors can maximize margin and ensure reliable inventory with our tiered program structure.

Essential OE-Plus

- Who it’s for: Distributors launching a Yamaha program + workshops needing a reliable “entry upgrade”

- Stock first: Mio/Fazzio/Fino + selected NMAX fast movers (your local volume platforms)

- How it makes money: High turnover + low claim risk → easiest tier to scale replenishment

Performance Adjustable

- Who it’s for: Workshops and dealers selling “feelable upgrades” with a clear adjustment story

- Stock first: NMAX + Aerox/NVX core movers (plus your top underbone platform if relevant)

- How it makes money: Margin pickup tier → upsell from Essential using “control & recovery” narrative

Premium / GT Line

- Who it’s for: Premium dealers + distributors building a flagship catalog (touring / premium riders)

- Stock first: XMAX + premium NMAX packages (only add after Tier 1/2 replenishment is stable)

- How it makes money: Premium positioning + higher ASP → “brand image SKUs” that anchor the catalog

Core Suspension Series for Yamaha

XMAX Q034

Aerox Q067

Nmax H158

Y15ZR/Y16ZR H301

Suspension Upgrades for Yamaha Underbone (Y15ZR / Y16ZR / LC135 / LC150) — High-Turnover & Durable Performance Program

The Limits of Stock Suspension

- High-frequency impacts and aggressive riding lead to early performance fade and inconsistent rebound feel

- Two-up use and uneven roads cause bottoming / harshness complaints, increasing workshop returns

- Owners demand visible upgrades; “no difference” products are hard to sell at a premium

Kingham Tech Engineering Advantage

- Durability-first build logic for high-mileage use (batch consistency + QC checkpoints to reduce claims)

- Traction-focused recovery tuning: stable rebound feel after repeated bumps (easy to explain and sell)

- Program planning: Core movers first → then premium upsell, with model-year fitment confirmed by email

JQ1006

H010

H114

H010B

H301

H161E

H161F

Performance Solutions for Yamaha XMAX — Touring Stability Program

Performance Deficiencies of Stock Unit

- High-Speed Oscillation: Lack of effective rebound damping control leads to chassis instability and a loose or “floating” sensation at highway cruising speeds.

- Limited Touring Capability: Inability of the factory unit to maintain consistent damping performance over long distances, often resulting in harshness and compromised long-term comfort.

Kingham Tech Engineering Advantage

- Large Piston Damping System: Utilizes a larger-diameter piston for maximized oil flow and precise damping forces, ensuring unwavering stability in high-speed corners.

- Convenient Remote Adjustability: Options for remote preload adjusters to allow riders to quickly compensate for luggage or a passenger, eliminating sag and maintaining optimal handling geometry.

Q064

Q034

H033

H012

H00A

H003

H124

Suspension Upgrades for Yamaha Aerox/NVX — Sport Scooter Response Progra

The Limits of Stock Suspension

- Inconsistent Damping Control: Leads to unpredictable chassis response and compromised high-lean stability.

- Insufficient Front-End Support: Excessive hydraulic travel consumption under high load (braking), resulting in geometry shift.

Kingham Tech Engineering Advantage

- Motorsport-Grade Piston Technology: Precision-machined damping pistons ensuring thermal stability and fade resistance for high-intensity use.

- Optimized Damping Curve Protocol: Tunable damping curves developed specifically for the AEROX/NVX chassis geometry, maximizing tire-to-road adherence.

Q039

Q045

Q067

H170

H012

H033

H022

H082M2

H133

Performance Solutions for Yamaha Mio / Fazzio / Fino — Entry Mobility Program

Performance Deficiencies of Stock Unit

- Harsh Ride Quality: Basic stock valving struggles to absorb sharp urban bumps and potholes, transferring excessive shock directly to the rider, reducing long-term comfort.

- Unsafe Braking Geometry: Soft front forks cause rapid and severe nose-dive under routine braking, leading to poor balance and extended stopping distances in emergencies.

Kingham Tech Engineering Advantage

- Refined Comfort Damping: Custom-developed valving stack optimized for low-speed urban use, effectively absorbing small road imperfections to deliver a noticeably smoother ride.

- Enhanced Spring & Preload Support: Implementing uprated linear springs and simplified preload adjustability, providing the necessary static support to maintain optimal chassis rake and stability.

Q041

Q042

H159

H188

H131

H130

H00A BLACK

H003

H124

Suspension Upgrades for Yamaha YZF-R15 — Entry Sportbike Control & Confidence Program

The Limits of Stock Suspension

- Under hard braking, riders feel front dive and unstable pitch, reducing confidence and perceived quality

- During fast transitions (brake → turn-in → accelerate), recovery is slow, leading to “floating” feedback

- Mixed rider weights and usage make “one-size tuning” hard for workshops to sell consistently

Kingham Tech Engineering Advantage

- Braking support & chassis stability positioning (clear selling line for shops: “more confidence, less dive”)

- Faster, controlled recovery for transitions (repeatable feel; lowers return risk)

- Program planning: Core control SKU(s) + premium upsell SKU(s), with fitment confirmation by model-year via email

H031

Suspension Upgrades for Yamaha Aerox/NVX — Entry Sportbike Positioning Program

The Limits of Stock Suspension

- High-Stress Component Fatigue: Stock rear shocks often exhibit rapid wear and tear under the aggressive riding common in this segment, resulting in premature failure and inconsistent performance.

- Sub-Optimal Weight Transfer: Ineffective damping during rapid throttle and braking hinders efficient weight transfer, compromising the traction and stability essential for high-speed cornering.

Kingham Tech Engineering Advantage

- Heavy-Duty Construction & Durability: Utilization of hard-anodized alloy components and oversized shafts, engineered to withstand the extreme torsional forces and high mileage typical of the R15 segment.

- Focused Rebound Control: Precisely tuned rebound damping to manage the lightweight rear swingarm and wheel assembly, ensuring instantaneous chassis recovery and peak tire contact for superior acceleration out of corners.

Q039

Q045

Q067

H170

H012

H033

H082M2

H133

JH030

Yamaha Scooter Starter Program

- Coverage: 6 core platforms (NMAX Series,XMAX Series,Aerox/NVX,Mio/Fazzio/Fino,Y15ZR/Y16ZR/LC135/LC150,YZF R15).

- SKU Count: 8-10 core SKUs across Essential / Performance / Premium.

- Business Focus: Fast turnover + margin protection.

Your Expert Partner in Suspension Manufacturing

Design & R&D

Our experienced R&D team, with over 15 years of industry expertise, develops more than 20 new products annually for our clients. Leveraging over 70 technical patents, we collaborate with customers to ensure their brands maintain sustained competitiveness in the market.

Advanced Manufacturing

Our modern manufacturing facility spans over 16,000 square meters, equipped with more than 90 CNC precision machines and a dedicated anodizing workshop. We utilize automated assembly and testing equipment while implementing comprehensive quality inspections to ensure every product meets the highest standards.

Global Partnership

With over 7 years of ODM/OEM service experience, we have successfully served aftermarket clients across Europe, the United States, and Southeast Asia. We provide comprehensive customization services, committed to becoming your most trusted suspension system solutions provider.

Performance Validation & Reliability Metrics

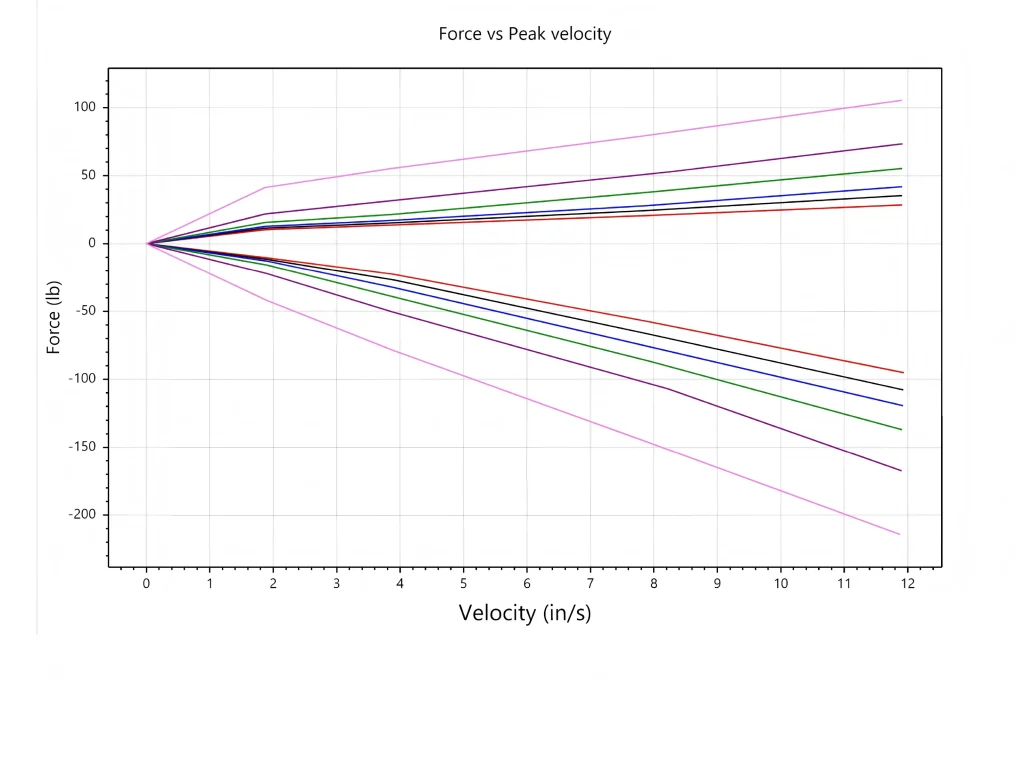

Quantified Damping Performance

This Force vs Velocity curve is the definitive proof of our performance. It confirms that our damping system maintains predictable force output and consistency, ensuring balanced and superior handling across all operating speeds.

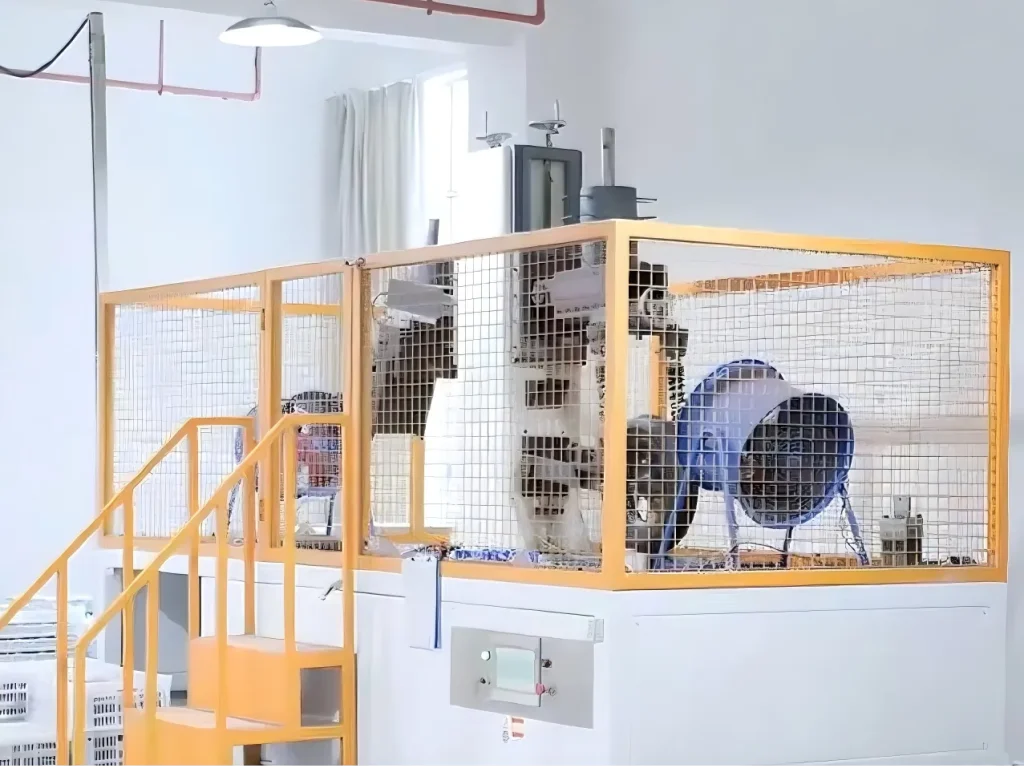

Structural Reliability

Testing

Critical components undergo rigorous fatigue testing on specialized equipment. This protocol validates the structural integrity of our components, providing partners with confidence in the long-term durability and warranty commitment.

Production Quality & Consistency

Every unit undergoes high-speed dyno validation to verify precision before packaging. This quality control step guarantees that all production batches meet the same high standard of control and stability.

Component & Environmental Verification

We confirm material integrity and component precision using dedicated inspection equipment. All external alloys are tested for superior corrosion resistance, confirming their durability in diverse global environments.

FAQ

Can we mix multiple platforms in one order?

Do you offer private label packaging?

What is the lead time for Yamaha suspension orders?

Can we adjust the damping settings?

Get a Yamaha Suspension Proposal

Share details about your Yamaha platforms. Usually reply within 1–2 days.