Motorcycle Shock Absorber

Manufacturer & OEM Suspension Supplier

- IATF 16949 & ISO certified factory with end-to-end in-house manufacturing.

- 100+ CNC machining centers and 3 independent production lines.

- 15+ years of R&D and 78+ technical patents.

- 92% of new brand clients expand to full series after first trial.

Choose How You Work with KINGHAM

Kingham Tech offers suspension solutions tailored to distributors, OEM/brands, and tuning workshops. Whether you're stocking parts or launching new products, we ensure the right fit for your business.

For Distributors & Importers

Build a suspension line-up that sells — with strong coverage on high-volume scooter and motorcycle platforms, consistent quality, and healthy margins.

- Wide platform coverage for fast-moving scooters & motorcycles

- Tier ladder (Value / Performance / Premium) to protect margins

- Stable lead time + reorder rhythm (monthly/quarterly replenishment)

For Brands (OEM/ODM)

- Platform-based development: targets → valving window → prototype

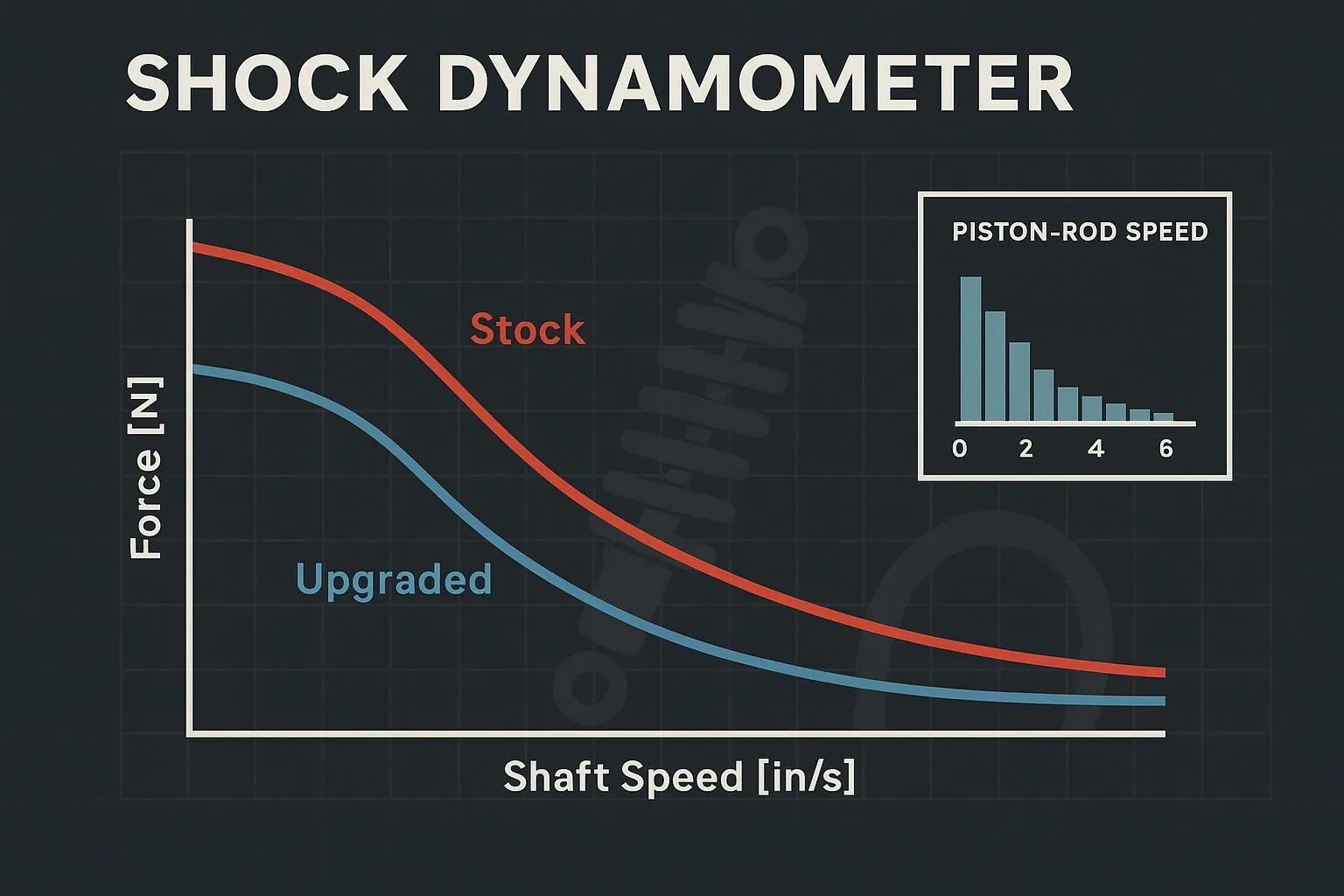

- Dyno curves + fatigue/salt-spray validation aligned to your spec

- Branding: color/laser logo/packaging + controlled SOP consistency

For Tuning Shops

Offer your riders rebuildable and tunable front & rear shocks with clear adjustment ranges, spare parts support and shock dyno data.

- Clear adjustment ranges + setup guidance per platform

- Spare parts & rebuild support for long-term service revenue

- Spec pack by email: fast fitment confirmation by model-year

Shop by Brand Platform

Start from the motorcycle brands that matter most in your market.

Kawasaki

Harley-Davidson

Aprilia

Shop by Products & Vehicle Type

By Product Family

By Vehicle Type

Motorbikes

Sport, commuter & touring.

ATV / UTV

High travel & impact resistance.

Golf Cart & RV

Stability & load capacity.

Why Partner with Kingham?

- National High-tech Enterprise

- Leading Small and Medium Enterprise

- Intellectual Property Advantage Enterprise

Engineered for Your Business's Success

End-to-End In-House Manufacturing

Self-owned mold workshop, CNC/NC workshops, and anodizing workshops.

Direct-from-Factory Advantage

Greater controls on quality and delivery.

Flexible OEM/ODM Customization

17 Expert R&D staff support full customization for Motorcycle Suspension OEM projects. Rapid turnaround: drawings in 10 days, samples in 30-45 days.

Market-Proven Reliability

Over 92% brand clients chose to work the whole shock absorber series with us after their first products' trial order.(data from 2022-2025 sales)

B2B Suspension Programs

SEA Scooter Distributor

Yamaha NMAX/XMAX Upgrade Ladder

Solution: Shared architecture across 3 price levels, coordinated colors.

Result: Higher average ticket per unit.

EU Harley Specialist

Touring & Dyna Heavy-Duty

Solution: Rebuildable twin shocks, higher load capacity.

Result: Improved ride ratings & repeat orders.

Aftermarket Brand

Kawasaki NINJA Performance Line

Solution: Monotube rear + performance front, backed by dyno data.

Result: Differentiated positioning vs low-cost rivals.

B2B Suspension Use Cases

Suspension Buyer Resources

Sourcing Motorcycle Shock Absorbers from China

Checklist for supplier evaluation, quality control and compliance.

Batch Consistency & Warranty Performance

How to think about batch stability and warranty risk.

Using Shock Dyno Data with Road Testing

Combining lab data with rider feedback for optimal tuning.

Heavy-Duty Supplier Criteria

Long-term criteria beyond unit price for utility vehicles.

Get a Suspension Program Quote

FAQ for OEMs, Distributors & Service Centers

What is your typical lead time?

Can I mix different models in one order?

Do you provide testing data and validation reports?

What kind of customization do you support?

2. We can customize body design, length, spring rate, stroke, installation parameters and adjustment functions

3. We can customize colors, logo, packaging, stickers and instructions