Sourcing motorcycle suspension systems has special challenges for OEM project managers. You need to find trustworthy suppliers. Quality assurance is very important in your choices. You must also handle lead times well to meet market needs. Knowing how pricing works can help you make smart decisions. By tackling these challenges, you can create a successful sourcing plan that improves your motorcycle products.

Key Takeaways

It is very important to find good suppliers for motorcycle suspension systems. You can use industry directories and trade shows to find reliable manufacturers.

Check suppliers by looking at their production ability and technology. Look for new equipment and strong research and development to make sure the quality is good.

Customization makes riding better. Offer features like electronic suspension adjustment and lightweight materials to fit different needs.

Know about lead times and what affects them. Good inventory management and logistics can help you meet market needs quickly.

Create long-term relationships with suppliers. Strong partnerships help with communication and quality control, making sure products perform well.

Supplier Sourcing for Suspension Systems

Finding good suppliers for motorcycle suspension systems is very important for your OEM projects. You want to make sure that the parts you get are high quality and work well. Here are some helpful ways to find potential suppliers.

Industry Directories and Trade Shows

Industry directories are great tools for finding top motorcycle suspension suppliers. Some of the best names are:

KYB Corporation: Provides many OEM and aftermarket motorcycle suspension systems.

Showa Corporation: Focuses on high-performance systems with electronic damping.

Fox Factory Holding Corp.: Specializes in premium off-road suspension solutions.

Öhlins Racing AB: Known for luxury and racing-grade suspension technologies.

Going to trade shows like CIMAMotor can also help your sourcing efforts. These events let you meet manufacturers and suppliers directly, showing their newest products. Meeting people at these shows can lead to good partnerships and teamwork.

Online Marketplaces and Platforms

Online marketplaces give you another way to find reliable motorcycle suspension parts. Here are two important platforms:

Marketplace | Description |

|---|---|

A special marketplace for automotive and motorcycle parts, including suspension systems. | |

Cogent Dynamics | Provides custom motorcycle suspension services and parts, including repairs and rebuilds. |

Being close to manufacturing places can really help your sourcing speed. Areas like Guangdong Province in China have factories that lower shipping costs and speed up delivery times. This group of manufacturers allows for quick testing and large production, which is key for the motorcycle industry.

By using these resources, you can find high-quality motorcycle suspension systems that fit your project needs.

Evaluating Quality and Performance

When you source motorcycle suspension systems, you need to check the quality and performance of suppliers. This helps you pick manufacturers who can provide high-quality parts that fit your project needs.

Production Capacity and Technology

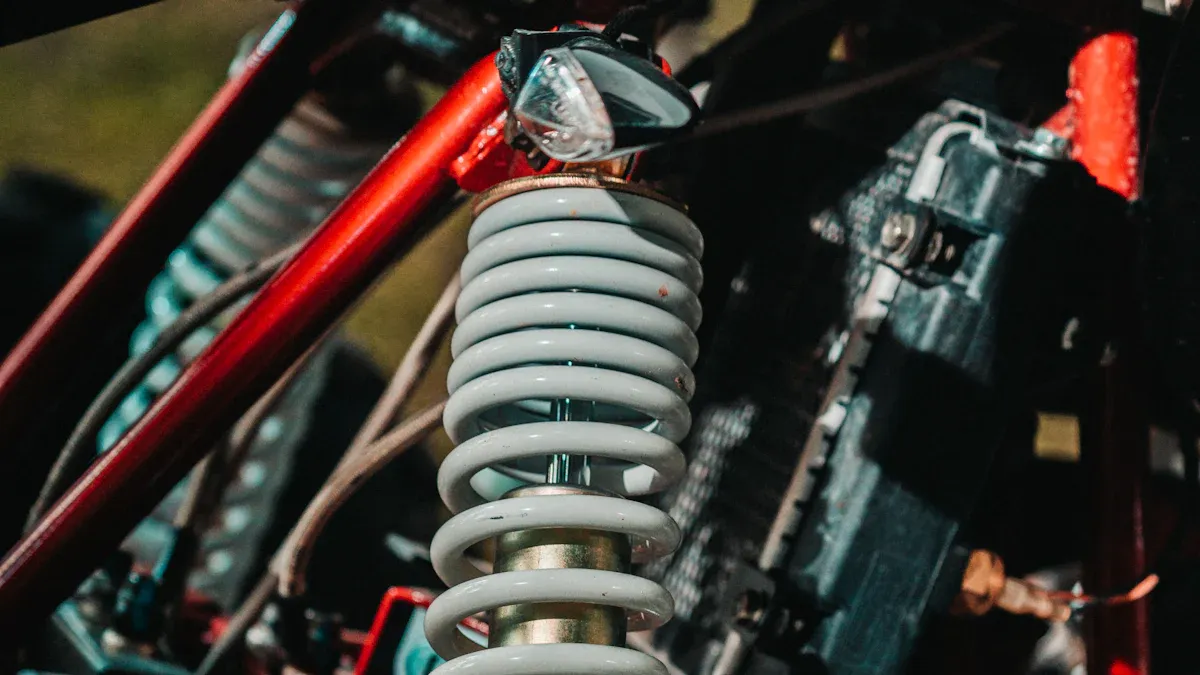

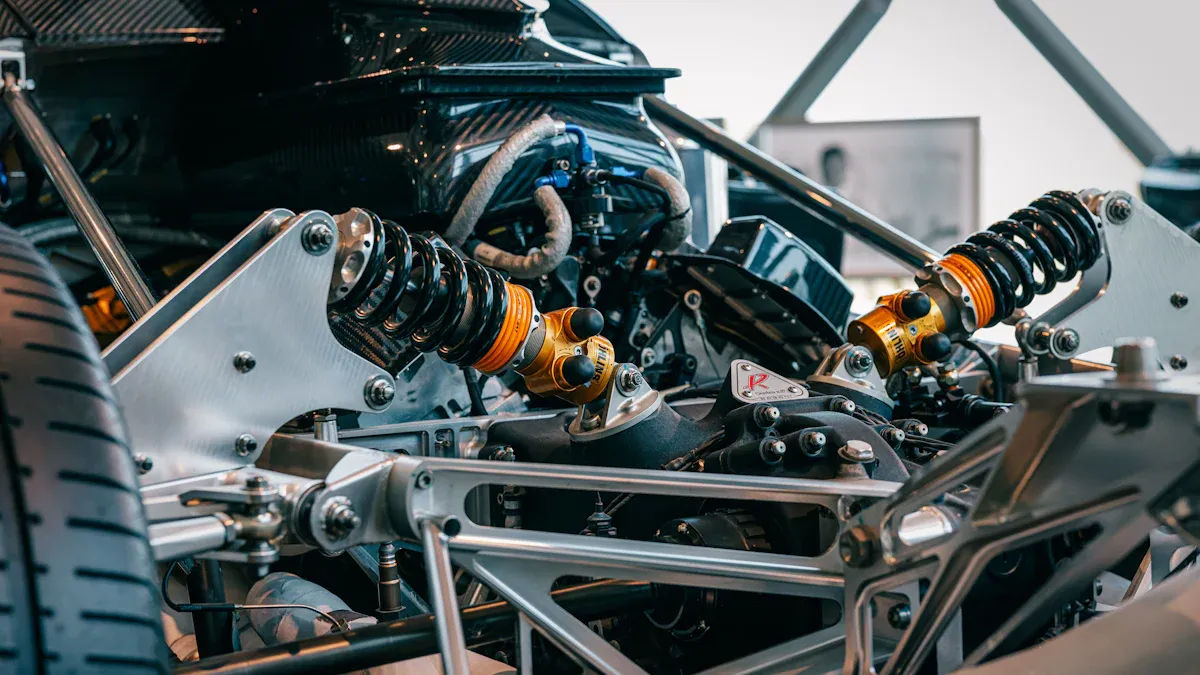

It is important to look at a supplier’s production capacity. You want to make sure they can meet your needs without lowering quality. Find suppliers with modern manufacturing technology. For example, Öhlins Racing has the CES (Continuously Controlled Electronic Suspension) system. This system uses advanced hydraulics and electronics. It allows control of each wheel based on road conditions and rider choices. This technology greatly improves ride quality and handling. It is very useful for high-performance motorcycle suspension systems.

Think about these factors when checking production capacity:

Machinery and Equipment: See if the supplier uses modern CNC machines and automated assembly lines. These tools help with precision and speed.

Production Volume: Make sure the supplier can produce the amount you need, whether it’s hundreds or thousands of units.

R&D Capabilities: A strong research and development team shows they care about improving their products.

Quality Control Measures

Quality control is very important to ensure the motorcycle suspension systems you get meet industry standards. Look for suppliers who follow known quality control standards. Here’s a list of some common standards:

Quality Control Standard | Description |

|---|---|

ISO 9001 | Ensures products and services are consistently good. |

IATF 16949 | Focuses on improving quality and preventing defects in the automotive field. |

ISO 14001 | Helps companies improve their environmental performance. |

ISO 45001 | Aims to make workplaces safer and reduce risks. |

VDA 6.3 | Checks how well processes work in the automotive industry. |

Social Compliance Audits | Ensure that operations follow social and ethical standards. |

Besides these standards, ask about the supplier’s quality assurance steps. Here are some key points to think about:

Quality Assurance Process | Description |

|---|---|

Evaluate Quality Management and Process Controls | Check how well quality management systems and document control work. |

Inspect Production, Material and Traceability Controls | Make sure you can trace materials from start to finish. |

Conduct On-Site Audits Including Staff Engagement | Do audits to see real production conditions and check staff skills. |

Performance testing is also very important for quality assurance. It makes sure the suspension systems work well in different situations. Common testing methods include:

Evaluation Method | Objective | |

|---|---|---|

Two-state skyhook damping | Describing-function evaluation in frequency-domain | Comfort and handling performance |

Linear skyhook damping | Describing-function evaluation in frequency-domain | Comfort and handling performance |

Two-state switching dampers | Describing-function evaluation in frequency-domain | Comfort and handling performance |

By carefully checking production capacity and quality control steps, you can confidently choose suppliers who will give you reliable motorcycle suspension systems that improve your products’ performance.

Customization in Suspension Solutions

Customization is very important when making motorcycle suspension systems for OEM projects. Riders have different likes and needs. By changing suspension solutions, you can make the ride better and meet different market needs.

Tailoring to Rider Needs

When you change motorcycle parts, you help meet specific rider needs. Here are some popular features in suspension systems:

Dynamic ESA (Electronic Suspension Adjustment): This feature changes damping automatically, making rides more comfortable and safe.

Lightweight materials: Using carbon fiber and titanium makes parts lighter, which helps performance and response.

Air suspension systems: These let you change ride quality easily for different conditions.

Race-spec suspension: This gives exact damping changes and improves grip by lowering the center of gravity.

AI-powered suspension: This new technology learns rider habits for the best performance.

These features not only make rides more comfortable but also improve handling and safety. By adding these customization options, you can make suspension systems for both casual riders and performance fans.

Collaboration with Suppliers

Working with suppliers is key to getting the best customization for suspension systems. You should find manufacturers that can offer a lot of customization and meet your needs. Here are some important parts of good collaboration:

Look for suppliers with an ISO-certified factory that can produce a lot.

Make sure they have many production lines and modern machines for quick development.

Check that they do thorough inspections for every OEM project to keep quality high.

Also, a strong partnership allows for these customization options:

Adjustable rebound damping for a smooth ride and good handling.

High-speed and low-speed adjustments for different riding conditions.

Custom spring preload settings for different weight loads.

A variety of hole pitch options for different motorcycle models.

Personalized stroke lengths for specific performance needs.

Kingham Technology shows this teamwork well. With a factory of 20,000 square meters and over 100 CNC machines, Kingham keeps quality high with full-line inspections. Their expert R&D team has 17 specialists who focus on full customization for OEM projects. This teamwork and innovation help you create high-performance motorcycle parts that stand out.

By focusing on customization and building strong supplier relationships, you can make motorcycle suspension systems that meet and exceed rider expectations.

Understanding Lead Times in Sourcing

Knowing about lead times is very important when sourcing motorcycle suspension systems. Lead times can change a lot based on different factors.

Factors Affecting Lead Time

Many things can affect the lead time for sourcing motorcycle suspension systems:

Supplier reliability is key. It affects how consistently parts are delivered.

Good inventory management helps you predict demand changes. This reduces the chance of running out of stock.

Shipping logistics, like choosing carriers and planning routes, can speed up delivery times.

Outside factors, such as the economy and market demand, can change lead times unexpectedly.

Typical lead times for major suppliers can be different. Here’s a quick overview:

Supplier | Lead Time |

|---|---|

Kawasaki Ninja ZX-10R | 30–60 days (standard), up to 90 days (custom/high-volume) |

LABA7 | 1–2 weeks (typical), up to 4 weeks (rare cases) |

Kingham CNC | 20-45 days (universal), 30-60 days (customized) |

Efficient Manufacturing Processes

To shorten lead times, you can use several smart strategies in your sourcing process. Think about these:

Strategy | Benefits |

|---|---|

Primary and backup suppliers | Reduces geographic risk |

Component-level segmentation | Faster delivery and less operational risk |

Hybrid sourcing strategies | Better compliance with local rules |

Also, you can improve efficiency by using modular subassemblies, standardized mounting interfaces, and customizable modules. These methods allow for quicker assembly and easier upgrades, which leads to shorter lead times.

By understanding these factors and using efficient manufacturing processes, you can greatly improve your sourcing strategy for motorcycle suspension systems. This will help you meet market needs while keeping high-quality standards.

Ensuring Quality Consistency

Keeping quality the same during production is very important for your motorcycle suspension systems. When quality is consistent, every part meets the needed standards. This helps improve performance and keeps riders safe. You need to have strong quality assurance processes to keep this consistency.

Quality Assurance Processes

Kingham Technology shows its focus on quality with different assurance methods. Here are some key practices:

Quality Assurance Method | Description |

|---|---|

Rigorous Testing | Products are tested before shipping to meet quality standards. |

Advanced Manufacturing | CNC machining and quality control help ensure precision and consistency. |

Customization | Tailored suspension solutions meet specific brand needs for the best performance. |

Kingham uses advanced tools like Coordinate Measuring Machines (CMMs) for accurate measurements. Optical Comparators find small flaws, improving the quality of the parts made. This focus on customization helps Kingham create unique suspension solutions based on client needs.

Building Long-Term Supplier Relationships

Creating long-term relationships with suppliers is key for keeping quality consistent. Strong partnerships lead to better communication and teamwork, which improves quality control. Suppliers can do regular quality checks to keep standards high across many production batches.

Quality Control Measure | Description |

|---|---|

Incoming Material Inspection | Each part is checked when it arrives to ensure it meets quality standards. |

Systematic Quality Checks | Parts are checked at different stages of manufacturing to catch defects early. |

Advanced Testing Equipment | Uses 3D measurement systems and durability testing chambers for accurate evaluations. |

Stringent Quality Control Protocols | Each production batch follows strict protocols with documentation and traceability. |

By building these relationships, you can make sure your suppliers stay focused on quality. This will help your motorcycle suspension systems and improve your brand’s reputation.

In conclusion, sourcing motorcycle suspension systems needs careful thought about some best practices. First, check the manufacturer’s registered address to avoid problems with fake addresses. Make sure you have correct customs paperwork and follow safety rules. Use strong packaging to keep your products safe during shipping. Also, pick the right shipping method for your needs.

Creating a strong suspension supply chain is just as important. Use different suppliers to avoid relying on just one. Map out your supply chain to see it better and find risks. Being flexible and adaptable will help you handle market changes well. By using these strategies, you can improve your sourcing process and boost the performance of your motorcycle products.

FAQ

What types of motorcycles can use Kingham’s suspension systems?

Kingham’s suspension systems work with many motorcycles. This includes popular brands like Yamaha, Honda, Kawasaki, Harley-Davidson, and Aprilia. Check the product details to see if it fits your bike.

How does Kingham ensure quality in its products?

Kingham uses strict quality control steps. They have ISO 9001 certification and use advanced manufacturing methods. They also do thorough performance testing. This makes sure every suspension system is high quality.

Can I customize the suspension systems for my motorcycle?

Yes, you can customize Kingham’s suspension systems. You can change features like spring preload, rebound, and compression settings. This helps you make the suspension fit your riding style.

What is the typical lead time for receiving suspension systems?

Lead times can change based on customization and order size. Usually, expect 20-45 days for standard orders and 30-60 days for custom solutions.

How can I contact Kingham for support or inquiries?

You can contact Kingham through their website’s contact page. They offer support for questions about products, customization, and technical help.