When you place a Rear Shock Order with a Chinese manufacturer, planning is very important. You must know key things like minimum order quantity (MOQ), mixing orders, and lead times. These factors affect how well you run your business and manage costs. For example, bigger orders might take longer to arrive, while smaller orders can cost more per item. By understanding these ideas, you can make smart choices. Working with trading agents or combining orders can help you deal with MOQ and lead times better. This way, you can enjoy the benefits of larger orders without spending too much money.

Key Takeaways

Know the Minimum Order Quantity (MOQ) to prevent extra stock and manage money well.

Combine different rear shocks in one order to meet MOQ and improve product performance.

Think about lead times by looking at order size, material availability, and seasonal issues to avoid delays.

Talk clearly with your manufacturer to make sure orders are correct and responses are quick.

Use a checklist before finishing your order to avoid mistakes and ensure quality.

What is MOQ?

Importance of MOQ

Minimum Order Quantity, or MOQ, is the least number of units a manufacturer wants you to buy in one order. Knowing about MOQ is very important when you plan your rear shock order. It affects how you buy and run your business.

When you deal with manufacturers, you will see that MOQ rules can change a lot. For example, small manufacturers usually set their standard MOQ at 50 units. Large manufacturers have the same MOQ but may ask for more units for custom orders. Here’s a quick comparison:

Manufacturer Size | Standard MOQ | Custom MOQ |

|---|---|---|

Small Manufacturers | 50 units | 500+ units |

Large Manufacturers | 50 units | 500+ units |

This table shows that both small and large manufacturers often have the same standard MOQs. But, the custom MOQ can be different, which is important to think about when planning your order.

Determining Your MOQ

Finding your MOQ means looking at your business needs and market demand. If you order too many because of high MOQs, you might end up with extra stock. This can slow down how fast you sell items and hurt your cash flow. On the other hand, if your MOQ matches your monthly demand, you can manage your stock well without overbuying.

To improve your inventory management, you should check your sales data and predict future demand. Knowing your market will help you make smart choices about your rear shock order. You want to make sure that your MOQ helps your business goals while keeping a good cash flow.

Mixing Orders for Rear Shocks

Benefits of Mixing

Mixing different types of rear shocks in one order has many benefits. Here are some important ones:

Enhanced Performance: Using various shocks can stop overheating during races. This helps a lot in high-speed or jumping situations.

Tailored Setup: Different shock designs can improve vehicle performance. They can be customized for specific needs, like towing. Manufacturers often use different shocks on the front and back of vehicles for the best results.

Diverse Applications: For example, KYB might use an Excel-G design in the front and a Gasajust in the back. Monroe could pair an OE Spectrum on the back with a Monromatic design in the front.

Effective Mixing Strategies

To mix your rear shock orders well, think about these strategies:

Increase Order Size: Try to make your order size bigger to meet MOQs better. This can help you avoid extra costs from smaller orders.

Optimize Review Period: Manage your inventory by optimizing the review period. Check your stock often to meet market demand without overbuying.

Consider Constraints: When setting MOQs, think about supply-side, demand-side, and internal limits. Knowing these factors will help you make smart choices about your rear shock order.

By using these strategies, you can get the most out of mixing orders while meeting your business needs.

Lead Times in Manufacturing

What Affects Lead Times?

Lead times for your rear shock order can change a lot based on different things. Knowing these things helps you plan better and avoid waiting too long. Here are some important factors that affect lead times:

Order Quantity: Bigger orders usually take longer to process. Manufacturers need more time to get materials and organize resources for larger batches.

Material Availability: If certain parts are popular or hard to find, this can make lead times longer. Always ask your supplier about material availability.

Production Capacity: How busy the manufacturer is affects how fast they can fill your order. If they are busy, you might have to wait longer.

Seasonal Fluctuations: Events like the Lunar New Year in China can really change lead times. Many factories close during this holiday, causing delays. It’s smart to keep extra inventory of 30-40% above average monthly sales and add 30-45 days to standard lead times during this time.

Logistics and Shipping: Problems with transportation, customs delays, and local trucking issues can also slow down how fast you get your order.

Calculating Lead Times

To figure out lead times for your rear shock order, follow these steps:

Make a bill of materials (BOM) for your product and list how many of each part you need.

Check the time from ordering materials to expected delivery for each BOM item, including supplier processing and shipping times.

Find the part with the longest lead time from the BOM to focus on it first.

Look at the production schedule to see when product quantities will be ready, keeping weekends and holidays in mind.

Calculate the administrative lead time for paperwork and choosing suppliers.

Calculate inter-operation lead time for tasks moving between work centers, including waiting and shipping times.

Add up all lead time parts to get the total manufacturing lead time.

By following these steps, you can better understand when to expect your order.

Tips for Managing Lead Times Effectively

Managing lead times well can help you keep things running smoothly. Here are some best practices:

Find Reliable Suppliers: Pick suppliers who can deliver on time and communicate well.

Reduce Inventory and Shorten Supply Cycle: Use Just-In-Time ordering to lower stock and lead times.

Optimize Supply Chain Processes: Make order processing faster and think about using smart software for real-time inventory tracking.

Understand Typical Lead Times: Lead times change based on order size. For example, orders of 1-20 sets usually take 7 days, while larger amounts need negotiation.

Identify Common Delays: Be aware of possible problems like:

Delays in container returns due to local trucking issues.

Customs delays from wrong paperwork.

Random customs checks at ports.

Using a supply chain value stream map can help you see the whole flow of products and information. This method lets you find areas that add to lead time. Working with suppliers can lead to good strategies for cutting down lead times.

Communicating with Kingham

Effective Communication Tips

Talking well with Kingham Technology is very important. It helps make sure your order is correct and that you are happy. Here are some good ways to improve your communication:

Be Clear and Concise: Use simple words when you talk about your rear shock order. Don’t use complicated terms that might confuse the manufacturer.

Ask Questions: Always ask if you don’t understand something about your order. Kingham usually replies quickly, within two hours. This helps you make changes on time and avoid mistakes.

Provide Detailed Specifications: Write down your needs clearly. Include sizes, materials, and any special requests. This helps Kingham know exactly what you want.

Follow Up Regularly: Keep in touch during the order process. Checking in often helps you know how your order is doing and if there are any problems.

Remember, good communication can lead to a reorder rate of less than 15%. This shows that customers are very satisfied.

Negotiating Terms

Negotiating terms with Kingham can really change how your order goes. Here are some tips to think about:

Recognize Hard-Bargaining Tactics: Know about tactics like “left at the altar” or “calling a higher authority.” Understanding these can help you stay in control during talks.

Use Psychological Techniques: If someone pressures you, act surprised. This can help you get back a strong position in the conversation.

Maintain a Strong Position: Once you agree on something, don’t try to change it again. This shows you are serious and helps build respect in your relationship.

By using these tips, you can create a good relationship with Kingham and make sure your rear shock order meets your needs.

Finalizing Your Rear Shock Order

Order Review Checklist

Before you finish your rear shock order, do a careful review. This checklist will help you make sure everything is correct:

Shock Size: Check the eye-to-eye length and stroke.

Hardware Size: Look at the top and bottom width and diameter.

Compatibility: Confirm stock stroke or over stroke and frame clearance.

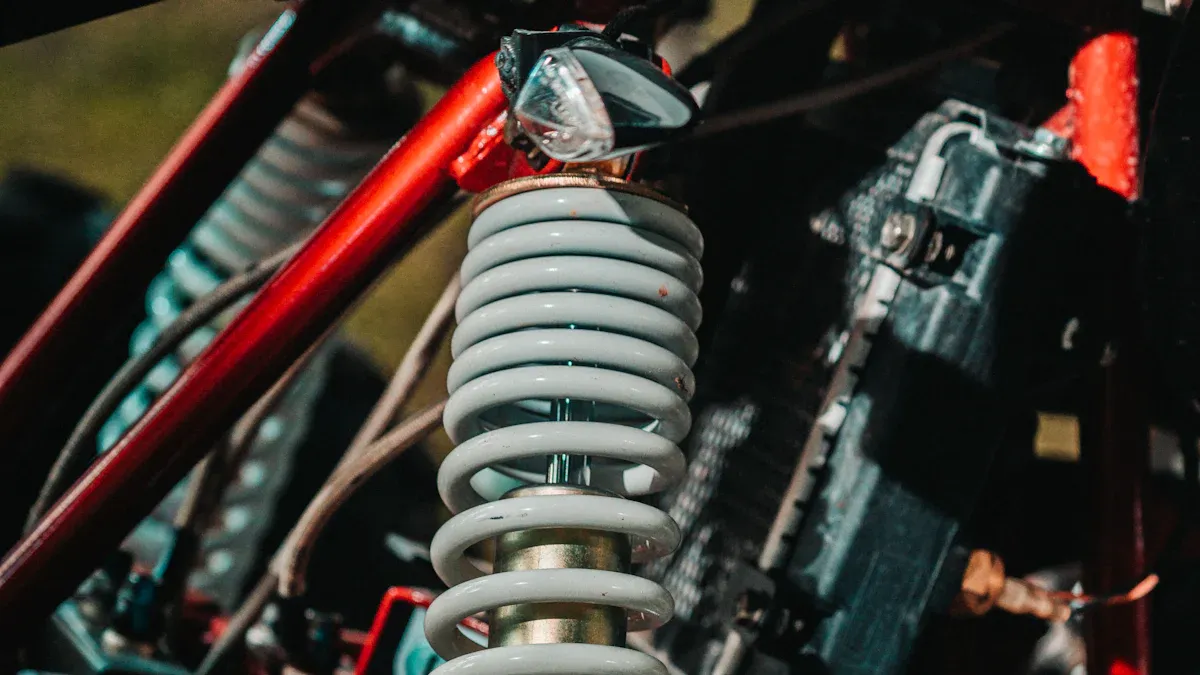

Coil or Air Shock: Choose based on bike design and rider choice.

Brand and Desired Shock Model: Make sure to specify the right model.

By using this checklist, you can avoid common mistakes during the final review. For example, wrong installation sizes can cause bad fitting of shock absorbers. Also, oil leaks can happen because of seal problems, but this is usually covered by warranty.

Payment Methods

For payment methods, you have a few choices. Most Chinese manufacturers, like Kingham, usually accept:

T/T (Telegraphic Transfer): This method needs 100% payment upfront to start work.

Knowing these payment methods is important for smooth transactions. Make sure to clarify payment terms before you place your order. This will help you avoid surprise costs and ensure your rear shock order is processed on time.

By following these steps and using the checklist, you can finish your order with confidence. This preparation will help you keep quality assurance and make the sourcing process easier for your products.

In conclusion, planning your first rear shock order with a Chinese manufacturer needs careful thought about many things. You should focus on how reliable the supplier is and if they have quality certifications. Using a tiered sourcing strategy can help you manage your inventory well. This means having one main supplier for regular stock, a second supplier for quick orders, and a special supplier for unique needs.

Knowing about MOQ, mixing orders, and lead times is very important for your success. Use metrics to check how reliable and good the suppliers are. Talk to suppliers about samples and prices to make smart choices. By doing these things, you can confidently place your first order with Kingham and improve your business operations.

FAQ

What is MOQ in rear shock orders?

MOQ means Minimum Order Quantity. It is the least number of units you need to order from a manufacturer. Knowing about MOQ helps you manage your stock and costs well.

How can I reduce lead time for my orders?

To cut down lead time, you can place bigger orders, check material availability, and talk clearly with your manufacturer. Being proactive about your order can help you avoid delays.

Can I mix different types of rear shocks in one order?

Yes, you can mix different types of rear shocks in one order. This way, you can meet MOQ needs while giving your customers a variety of products.

What factors affect lead time when manufacturing in China?

Lead time can change based on order size, material availability, production capacity, and shipping. Seasonal changes, like holidays in China, can also affect how fast you get your order.

How do I communicate effectively with my manufacturer?

To communicate well, be clear and simple about what you need. Ask questions if you don’t understand something, give detailed specifications, and check in regularly to stay updated on your order status.