Sourcing good motorcycle shock absorbers from China is very important for your business. In 2023, China is expected to sell motorcycle parts worth $1 billion. This shows how important it is in the world market. To make sure you buy successfully, focus on these key steps:

Check if the supplier is trustworthy to avoid wrong information.

Manage costs well, including shipping and taxes.

Deal with language problems that might come up.

Follow laws to keep products safe.

Protect your ideas to avoid design problems.

By following these steps, you can handle the challenges of sourcing and improve your supply chain.

Key Takeaways

Make sure your supplier is trustworthy. This helps avoid wrong information and guarantees good products.

Control costs well, including shipping and taxes. This helps keep your profits.

Learn about the production process. This helps you make smart choices about quality and performance.

Look for needed certifications. This ensures safety and quality rules are followed.

Keep up with rules and work with experts. This helps make the import process easier.

Manufacturing Landscape in China

China makes a lot of motorcycle shock absorbers. This industry is lively and changing fast. Many important manufacturers lead the market. They offer different products to meet many needs. These companies care about new ideas and quality. They want their products to be good both in China and around the world.

Key Manufacturers

Some well-known shock absorber makers in China are:

Kingham Technology

YSS Suspension

Showa Corporation

Öhlins Racing

These companies spend a lot on research and development. They use modern methods to make high-quality shock absorbers for different types of motorcycles.

Market Trends

The market for motorcycle shock absorbers in China is growing quickly. More riders want better suspension systems. About 45% of them want performance upgrades. Around 38% of motorcycle users care about suspension quality when buying. Also, nearly 52% of new installations use advanced shock absorber technologies. This improves stability and customization.

New technology changes are also affecting this market. Here are some important innovations:

Description | |

|---|---|

Smart Sensors | These help adjust suspension in real-time based on road conditions for better safety and comfort. |

Adaptive Damping Systems | These change stiffness automatically for better handling, especially for electric vehicles. |

Eco-friendly Materials | These focus on being green with recyclable materials and easy designs for disassembly later. |

As manufacturers use lighter materials and smart tech, China becomes a big player in the global market. Advanced suspension systems improve ride comfort and safety. This makes these products very important for modern motorcycles.

Choosing Shock Absorber Manufacturers

When you pick shock absorber manufacturers, check their reputation and skills. This helps you work with trustworthy companies that meet your quality and performance needs.

Evaluating Reputation

To check a manufacturer’s reputation, think about these points:

Credentials: Make sure they have export licenses and certifications like ISO 9001. This shows they care about quality management.

Production & Quality: Look at the factory’s ability and quality control methods. Find out about defect rates and product testing to ensure they are reliable.

Reputation: Research the manufacturer’s background through online reviews and feedback from other buyers. This helps you see if they are trustworthy.

R&D: Think about how much they invest in research and development. A strong focus on new ideas keeps them competitive.

By looking at these factors, you can make smart choices about which manufacturers to trust for your motorcycle shock absorber needs.

Certifications and Capabilities

Certifications are very important for knowing the quality and safety of motorcycle shock absorbers. Here are some common certifications from good manufacturers:

Certification | Description |

|---|---|

Emission standard compliance | |

ISO | International quality standard |

CE | European safety standard |

EPA | Environmental protection compliance |

DOT | Department of Transportation standards |

These certifications show that the products meet global standards for quality and safety.

Besides certifications, think about the manufacturing skills of possible suppliers. Top motorcycle suspension manufacturers usually do well in these areas:

Capability Type | Description |

|---|---|

Suppliers provide custom designs for different vehicle types, ensuring tailored solutions for clients. | |

Technological Innovation | Focus on high technology and ongoing innovation to improve product quality and performance. |

Quality Assurance | Commitment to high-quality products and good after-sales service to keep customers happy. |

By paying attention to these points, you can find manufacturers that not only meet your needs but also help improve the performance and durability of your motorcycle shock absorbers.

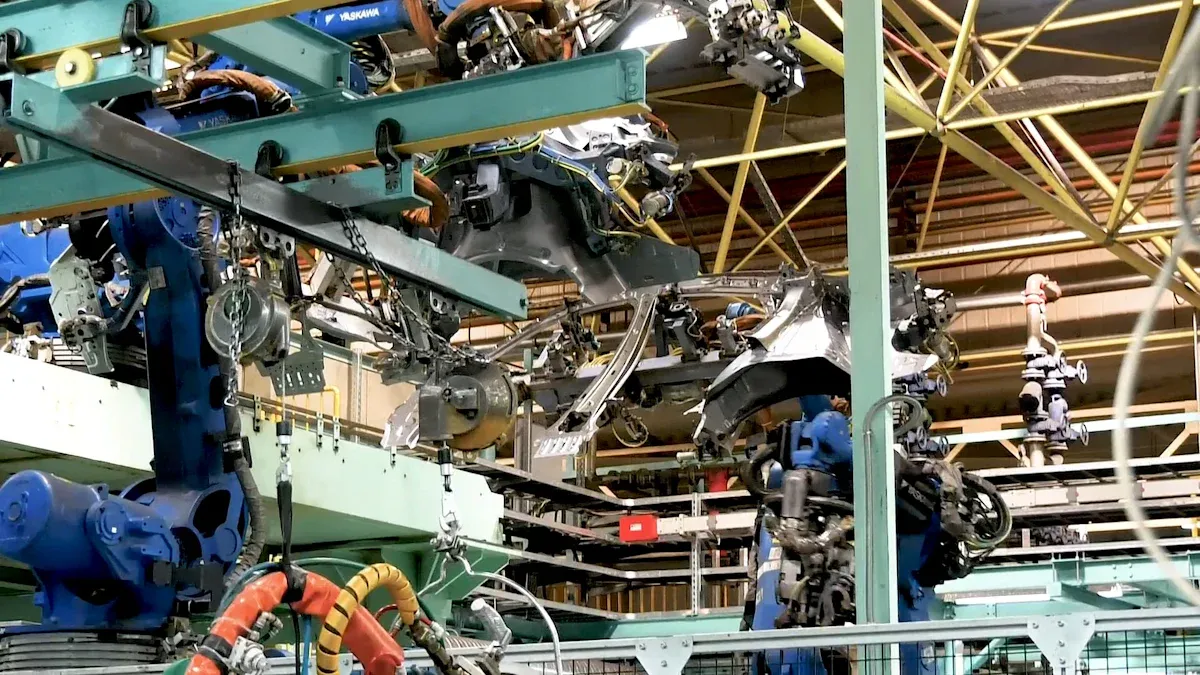

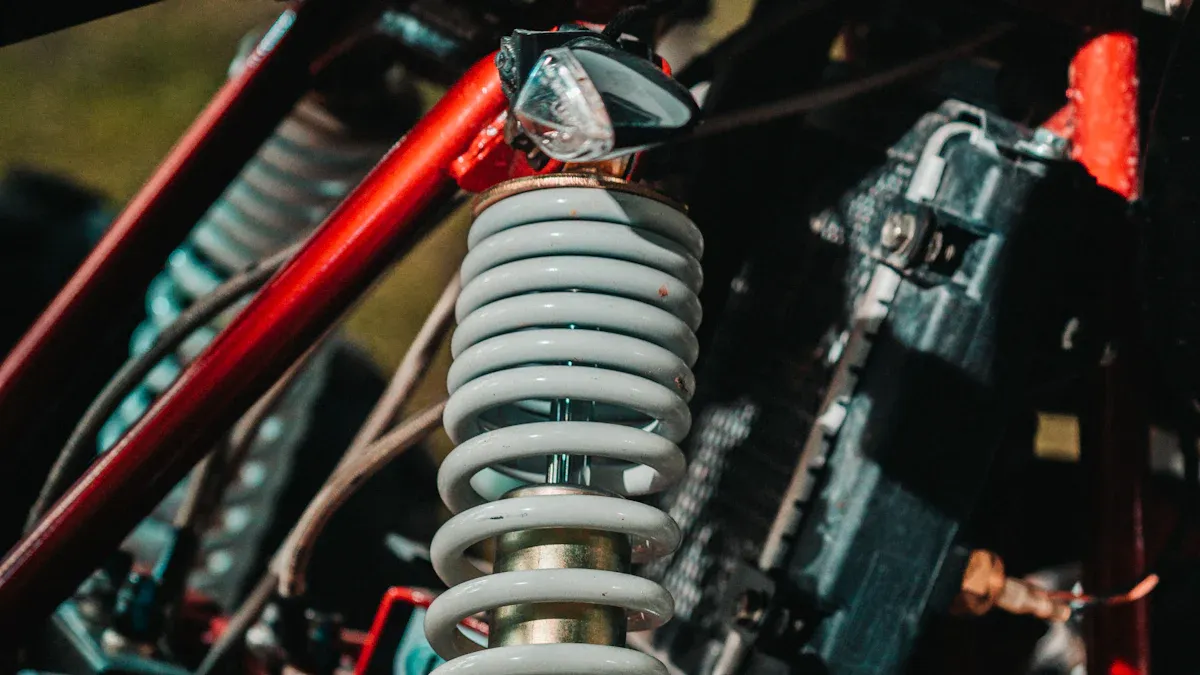

Motorcycle Shock Absorber Production Process

Making motorcycle shock absorbers involves several important steps. Each step helps make sure the final product is high quality, works well, and lasts a long time. Knowing this process helps you see how complex and precise making these parts can be.

Design and Prototyping

The design stage is very important for making good motorcycle shock absorbers. Manufacturers often use special CAD software to create detailed designs. This software helps engineers make 3D models of the shock absorbers. By simulating real-life conditions, they can improve designs using finite element analysis (FEA). This method allows quick changes before actual production starts.

After designing, manufacturers create prototypes to test how well the shock absorbers work. This step is key for finding any problems early on. By using CNC machining, manufacturers can make prototypes that look like the final product. This way, the prototypes meet the needed specifications and performance standards.

Assembly Techniques

Once the design and prototyping are done, the assembly process starts. This process has several key steps that help ensure the quality of the shock absorbers. Here’s a list of the main steps in making motorcycle shock absorbers:

Step | Description |

|---|---|

Compacting | Uses 25T-150T compacting machines to shape the shock absorber parts. |

Sintering | Heats the compacted powder to stick particles together without melting them. |

Machining | Creates complex shapes that powder metallurgy cannot form, like holes and threads. |

Blackening | Uses steam treatment to add an oxide layer for rust protection and more hardness. |

Hardening | Increases strength and hardness through methods like carburizing or nitriding. |

Inspecting | Checks quality and performance using BLUE inspection standards before shipping. |

Packaging | Uses anti-rust paper and vacuum methods to keep the product safe during transport. |

These steps make sure the shock absorbers work well and are reliable. Manufacturers in China usually take 25 to 45 days to produce after getting approval. Some suppliers can even finish in less than 30 days because of their efficient workflows. This speed is a big plus in the competitive market.

By knowing the production process, you can make smart choices when buying motorcycle shock absorbers. This understanding helps you ensure that the products you select meet your quality and performance needs.

Quality Control in Motorcycle Suspension

Quality control is very important for making good shock absorbers. It makes sure that every product works well and lasts a long time. You need to know the main testing standards and steps that manufacturers use to keep quality high.

Testing Standards

In China, there are several testing standards for making motorcycle shock absorbers. These standards help make sure that products are safe and dependable. Here are some important standards:

Standard Type | Code | Description |

|---|---|---|

Voluntary | Motorcycle shock absorber | |

Voluntary | QC/T 62-2021 | Motorcycle and moped shock absorbers |

These standards help manufacturers create shock absorbers that meet both local and global needs.

Implementing QC Processes

To keep high-quality standards, manufacturers use different quality control steps. Here are some key stages:

Quality Control Stage | Key Focus Areas |

|---|---|

Incoming Quality Control (IQC) | Size accuracy, Material quality, Surface issues |

In-Process Quality Control (IPQC) | Important torque values, Assembly order, Process mistakes |

Final Inspection and Testing | Electrical checks, Engine start and idle tests, Brake and suspension checks |

By focusing on these areas, manufacturers can reduce problems and make customers happier. Good quality control systems are necessary for steady product quality. Regular factory checks help find ways to improve, making sure you get reliable products.

Regulatory Compliance for Importing

When you bring in motorcycle shock absorbers from China, you need to follow certain rules. These rules make sure the products are safe and good quality. Knowing these rules helps you avoid delays and fines.

Necessary Certifications

Before you import, check for important certifications. These certifications show that the shock absorbers meet global standards. Here are some key certifications to look for:

Certification | Description |

|---|---|

ISO 9001 | Quality management system certification |

CE | European safety standard |

DOT | Department of Transportation compliance |

EPA | Environmental protection compliance |

These certifications prove that the manufacturer keeps high quality and safety in their products. Always ask your supplier for copies of these certifications.

Navigating Compliance Challenges

Importing can have challenges. You might deal with customs clearance, paperwork, and local laws. Here are some tips to help you manage these challenges:

Stay Informed: Keep updated on rule changes. Laws can change often, affecting your imports.

Work with Experts: Think about hiring a customs broker. They can help you understand the paperwork and ensure compliance.

Prepare Documentation: Make sure you have all needed documents ready. This includes invoices, packing lists, and certificates of origin.

By following these steps, you can make the import process smoother and ensure your motorcycle shock absorbers meet all rules. This care protects your business and improves your reputation in the market.

Logistics and Shipping Solutions

Customs Clearance

When you bring in motorcycle shock absorbers from China, you need to go through customs clearance. This process checks that your products follow all laws before they enter your country. Here are the important documents you need for easy customs clearance:

Document Type | Description |

|---|---|

Bill of Lading | Confirms that the shipping company received the cargo. This is important for tracking. |

Commercial Invoice | Shows the value, amount, and sale terms. This helps customs figure out duties and taxes. |

Import Declaration | A formal statement to customs about the shipment. |

Certificates of Origin and Compliance | Proves where the products come from and that they follow local rules. More tests may be needed. |

Make sure to get these documents ready in advance. This helps prevent delays and makes the import process easier.

Delivery Timelines

Knowing delivery timelines is important for planning your stock and meeting customer needs. The time it takes for motorcycle shock absorbers to arrive from China can change based on the supplier and shipping method. Here’s a look at typical delivery timelines:

Supplier | Delivery Timeline |

|---|---|

Supplier 1 | 15 ~ 30 days |

Supplier 2 | 1-7 days (in stock), 20-30 days (made to order) |

Supplier 3 | 20-45 days (standard), 30-60 days (customized) |

By understanding these timelines, you can manage your supply chain better. This way, you will have the right products when your customers want them. Always talk to your suppliers for the most accurate order estimates.

By following these logistics and shipping tips, you can make your import process smoother and improve how you source motorcycle shock absorbers from China.

Kingham’s Custom Solutions

Kingham Technology has many custom options for motorcycle shock absorbers. These options fit different needs, so you can find what works best for your brand. Here’s what they offer:

Product Offerings

Kingham gives OEM buyers several ways to customize. You can pick from different prices and features to match your needs. Here’s a list of the choices:

Customization Option | Price Range | Features |

|---|---|---|

Entry-Level | Better stability and comfort | |

Mid-Range | $1,095 | Adjustable settings for better performance |

Premium | $1,499 | Remote adjustability and improved damping control |

These choices help you pick shock absorbers that make riding better for your customers.

Advantages of Kingham’s Solutions

Kingham’s OEM/ODM options have many benefits that make them stand out from other shock absorber makers. Here are some key advantages:

Advantage | Description |

|---|---|

Kingham makes special suspension systems that fit specific brand needs. | |

Advanced Technology | Uses new research and manufacturing methods for better performance. |

Quality Assurance | Follows strict quality checks and has certifications like IATF 16949. |

Cost-Effectiveness | Improves manufacturing efficiency, giving quality solutions at fair prices. |

Global Reach & Support | Provides strong support and a wide network for successful project execution. |

By choosing Kingham, you get high-quality motorcycle shock absorbers made to fit your needs. Their advanced technology and focus on quality ensure you receive reliable products that boost your brand’s reputation.

In conclusion, getting motorcycle shock absorbers from China needs careful planning and action. You should pay attention to these important areas:

Evaluate Manufacturers: Look at their reputation and certifications.

Understand Production Processes: Learn about the steps in making the products.

Implement Quality Control: Make sure to keep high standards with testing and checks.

Doing thorough research and being careful can really help your success in buying. Think about these points:

Evidence Type | Description |

|---|---|

Supplier Certifications | Make sure suppliers have well-known certifications like ISO 9001. |

Third-Party Inspections | Ask for inspection reports from companies like SGS or TÜV. |

Communication Efficiency | Quick communication helps teamwork. |

Holistic Evaluation | Choose manufacturers that are open about their production processes. |

By following these steps, you can improve your sourcing plan and get high-quality products for your customers.

FAQ

What types of motorcycles work with Kingham’s shock absorbers?

Kingham’s shock absorbers fit many motorcycles. This includes popular brands like Yamaha, Honda, Vespa, and Aprilia. Check the product details for compatibility.

How long does it take to get an order from Kingham?

Delivery times depend on the supplier. Usually, expect 15 to 45 days for regular orders. Custom orders might take longer, so always check with your supplier.

What certifications should I look for when buying shock absorbers?

Look for certifications like ISO 9001, CE, and DOT. These show that the products meet global quality and safety standards.

Can I change the shock absorbers for my brand?

Yes, Kingham provides OEM/ODM services. You can change features, materials, and designs to fit your brand’s needs.

What quality control steps does Kingham use?

Kingham has strict quality control steps. This includes checking incoming parts, in-process checks, and final testing. This makes sure every shock absorber meets high performance standards.