Choosing the best manufacturer for your motorcycle front fork upgrade is very important. It affects how well your bike performs and how safe it is. Good materials make your bike last longer and work better, which is key for safe riding. Precise engineering in fork design helps with handling and stability. You can have more control and comfort with adjustable features. These features let you change things based on your riding conditions.

Think about the reputation of the manufacturers. Ask important questions about their engineering skills and material quality. Your choices can greatly change your riding experience.

Key Takeaways

Picking the right manufacturer is very important for performance and safety. Look into their reputation and engineering skills.

Match your performance goals with what the market needs. Focus on features that interest your target audience, whether they are racers or commuters.

Make sure it works with current motorcycle models. Know how changes in shape and size can affect handling and stability.

Choose strong materials for durability and performance. Good materials can make your motorcycle forks last longer and work better.

Follow industry rules and standards during testing. This keeps safety and reliability in check, which are important for rider confidence.

Fork Upgrade Considerations for New OEM Projects

When you think about upgrading a motorcycle front fork, you need to balance performance goals with market needs. Your performance goals should match what your audience wants. For example, if you want to attract racing fans, focus on features like adjustable damping and lighter weight. But if your target market is daily commuters, you should focus on comfort and reliability.

Performance Targets vs. Market Positioning

Knowing your performance goals helps you find your product’s unique selling points. You should ask yourself:

What specific upgrades do you want?

How do these upgrades fit with your brand’s image?

Are you targeting a small market or a larger audience?

By answering these questions, you can create a clear plan for your motorcycle front fork upgrade. This plan will help guide your design and engineering choices, making sure your product meets both performance needs and market demands.

Compatibility Constraints with Existing Platforms

Compatibility is very important when adding upgraded forks to current motorcycle models. You might face several challenges, such as:

Differences between front and rear wheel sizes, which can change balance.

Changes in geometry that may affect handling.

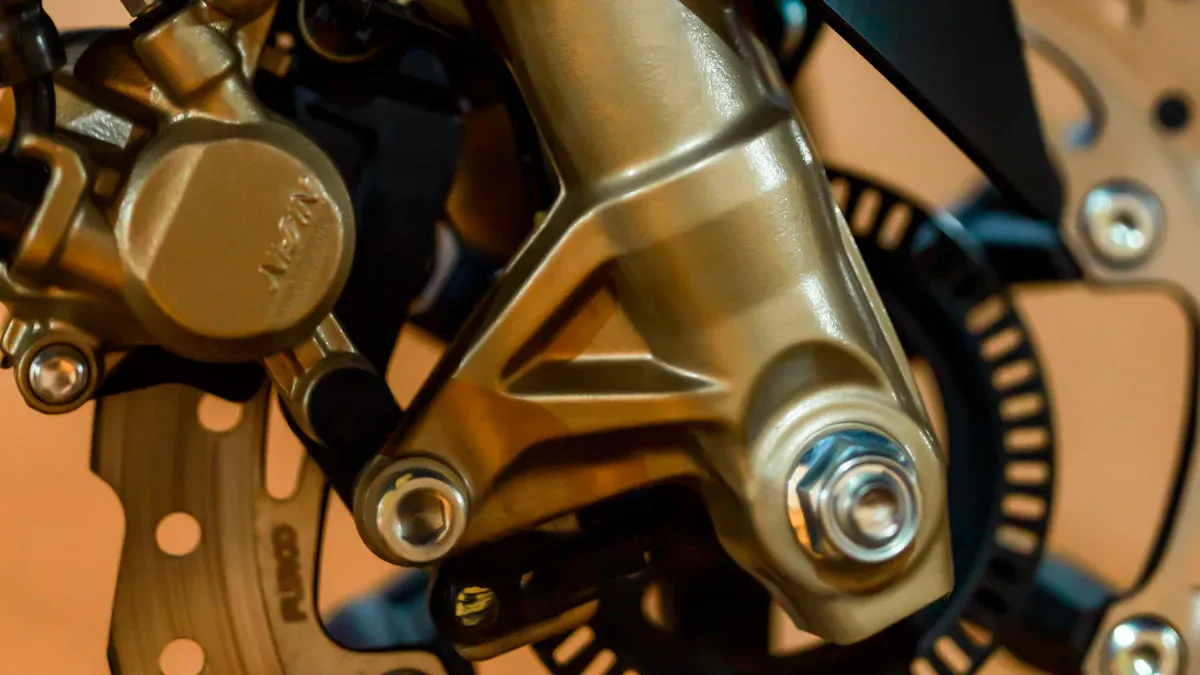

Brake parts that may need adjustments for proper fit and performance.

These compatibility problems can change the overall riding experience. So, you must do thorough research on existing models before making any changes.

Following regulations is also very important when choosing manufacturers for motorcycle front fork upgrades. Manufacturers must follow different regional rules and safety standards. These rules affect material choices and design requirements. For example, a front fork must handle impacts while not creating extra dangers, like breaking into sharp pieces during a crash. This balance is key for rider safety and is influenced by regulations.

Choosing materials is also linked to compliance. While carbon fiber is popular for being strong and light, its long-term performance in different conditions must meet regulatory standards. This affects both the product’s performance and its costs over time.

Technical Specs and Geometry Impact

Upgrading your motorcycle forks means knowing how technical specs and geometry affect handling. The design of your front fork is very important for how your motorcycle works on the road.

Geometry Changes and Handling Trade-offs

When you change the geometry of your motorcycle forks, it can greatly affect handling and stability. Important factors include:

Parameter | Effect on Handling and Stability |

|---|---|

Affects how quickly you can steer and stability at high speeds. | |

More trail makes it stable but harder to turn. | |

Axle Offset | Changes the height of the front end and affects the trail. |

More trail improves stability, especially when going fast. But it can make your motorcycle tougher to turn. You need to find a balance to get the riding experience you want.

Material Selection and Durability Expectations

Picking the right materials for your motorcycle front fork upgrade is key for performance and how long it lasts. Common materials are:

Material Type | Durability Features |

|---|---|

Lasts long and resists rust | |

Zinc-Plated Components | Lasts longer and looks good |

Low-Friction Bushings | Works better and wears down less |

High-Performance Seals | More reliable and needs less maintenance |

Using good materials helps your forks handle the tough conditions of riding. For example, anodized parts resist rust well, which is important for lasting a long time.

Manufacturer Evaluation for Front Fork Upgrade Programs

When you look at manufacturers for your motorcycle front fork upgrade, pay attention to their engineering help and teamwork skills. These things can really affect how well your project does.

Engineering Support and Co-Development Capability

A good partnership with your manufacturer can improve your product’s performance and fit in the market. Here are some important points to think about:

Evidence Description | Key Points |

|---|---|

Modular product platform | |

R&D consultation services | Offers expert advice for improving and fitting products. |

Rapid prototyping | Quickly checks physical fit, speeding up project time. |

Real-world testing | Makes sure products meet different customer needs and performance goals. |

By using these skills, you can make sure your motorcycle front fork upgrade meets what your target market wants. This teamwork can lead to new designs and better performance.

Production Capacity, QC and Consistency at Scale

Next, check the production ability and quality control of possible manufacturers. Good manufacturers have strict processes to keep quality high in mass production. Here are some methods they use:

Strict quality control steps, including full size checks.

Use of CMM (Coordinate Measuring Machine) reports.

Material certifications to ensure quality.

Also, following ISO 9001 and IATF 16949 certifications shows that manufacturers keep high quality from design to production. They stick to international standards all through the process, ensuring quality from raw materials to finished products.

Top motorcycle front fork manufacturers stand out by using advanced materials like aluminum and carbon fiber. These materials improve performance and durability, helping with shock absorption and handling. As the market changes, manufacturers that create lightweight solutions are more likely to gain market share. This focus on lowering weight while keeping strength meets the growing demand for efficient and high-performance suspension systems.

Project Risks, Validation and Installation Readiness

Upgrading your motorcycle front fork has some risks and things to think about. You need to focus on how well parts fit together and the risks during assembly to keep everything safe and working well.

Installation Tolerance and Assembly Risks

If the installation is not done right, it can cause serious safety problems. Here are some common assembly risks to know about:

Issue | Description |

|---|---|

The front fork tube pinch bolts might not be tightened enough during making. | |

Safety Impact | If the clamp pressure is too low, the tubes can slide, which raises the chance of losing control and crashing. |

Warranty Implications | Problems can lead to warranty claims since manufacturers need proof for repairs related to safety issues. |

To avoid these problems, always follow the manufacturer’s installation instructions. Use a torque wrench to make sure all parts are tightened correctly.

Testing, Validation and After-Sales Implications

Before you sell your upgraded forks, you need to check their performance. Following industry standards is very important. Here are some key testing needs:

Standard/Requirement | Description |

|---|---|

Make sure the fork meets ISO or SAE standards for strength and load capacity. | |

Compatibility | Check that it fits with the current frame geometry (like a 1-1/8″ steerer tube and 15x110mm Boost axle). |

Safety Regulations | Ensure it follows local safety rules, especially for e-bikes. |

Shock Absorption | Focus on products that have proof of shock absorption tests and resistance to wear. |

Third-party Validation | Look for suppliers that provide third-party lab tests or real-world results. |

After installation, proper debugging is very important. This step makes sure everything works safely and correctly. You should also think about after-sales service. Here are some steps to take:

Assess your needs: Decide if you are fixing, upgrading, or building a custom bike.

Determine fork compatibility: Make sure new forks fit your current setup.

Choose service level: Pick between a basic rebuild or performance revalving.

Get multiple quotes: Compare prices and services from different providers.

Verify technician expertise: Look for certified mechanics with good reviews.

Ask about warranty: Good shops should offer labor warranties.

Confirm turnaround time: Plan for how long the service will take based on your transport needs.

By following these tips, you can improve the safety and performance of your motorcycle front fork upgrade.

Picking the best manufacturer for your motorcycle front fork upgrade is very important. You need to do careful research to check quality and fit. This helps keep riders safe and makes them happier.

Custom builds can improve performance and safety checks, which is key for rider trust.

More than 40% of motorcycle fans say they feel happier after custom upgrades.

Using OEM parts helps keep resale value high, since buyers like motorcycles with real parts.

Focus on these points to make a better riding experience and keep your motorcycle working well.

FAQ

What are the benefits of upgrading my motorcycle’s front fork?

Upgrading your motorcycle’s front fork improves handling, stability, and comfort. You get better control over your ride, especially in tough conditions. Custom forks also let you make changes based on your riding style.

How do I know if a fork upgrade is compatible with my bike?

Look at your motorcycle’s specifications and compare them with the fork’s details. Check for compatibility with your bike’s frame shape and axle size. Ask your manufacturer or a trusted dealer for help.

Can I install the upgraded forks myself?

You can install upgraded forks yourself, but it needs mechanical skills and the right tools. If you’re not sure, think about hiring a professional mechanic to make sure it’s safe and done right.

What materials are best for motorcycle front forks?

High-quality aluminum and steel are good choices for strength and performance. Anodized parts resist rust, while low-friction bushings help with handling. Pick materials based on your riding needs and conditions.

How often should I replace my motorcycle’s front forks?

Change your motorcycle’s front forks when you see signs of wear, like leaks or less performance. Regular checks help you spot problems early, keeping your ride safe and enjoyable.