Kawasaki Motorcycle Suspension Programs

Manufacturer & OEM/Wholesale Supplier

- IATF 16949 & ISO 9001 certified processes guarantee reliable quality

- In-house CNC machining + anodizing control for premium consistency

- Built for "Sport", "Touring", and "Streetfighter Programs"

- OEM/ODM support for new platform development

Built for Kawasaki Distributors, Brands and Workshops

Kawasaki performance platforms serve different buyer needs—street upgrades, track-day tuning, or competition setups. Plan your program with clear tiers and a fast “spec pack by email” workflow.

Distributors & Importers

Build a tiered Kawasaki program with manageable SKUs (NINJA / KR / KRR). Start with 8–12 “core movers”, then expand by tier depth and model-year coverage.

Aftermarket & OEM Brands

Rebrand proven shock families or co-develop damping targets for sport platforms. Validation materials available upon request (dyno/QC/consistency).

Tuning Shops & Service Centers

Offer tunable upgrades with clear adjustment guidance for street + track setups. Spare parts and claim workflow supported by email.

Ready to see the data?

Kawasaki Performance Platform Overview

Kawasaki performance demand is highly segmented. This page focuses on three high-intent programs we can support efficiently for B2B buyers: NINJA (street/track-day), KR 150 (two-stroke street), and KRR 150 (race-focused). Build your catalog by tier first, then confirm fitment by model-year via our spec-pack-by-email workflow.

Platform

Typical Role

Key Markets

Main Suspension Opportunities

NINJA Series

Sport platform (street + track-day)

Global / SEA sport markets

Cornering stability, braking dive control, track-day fade resistance

KR 150

Lightweight two-stroke street performance

SEA

High-speed composure, spring support, predictable rebound control

KRR 150

Competition-focused two-stroke

SEA racing / enthusiast

Thermal stability, bottom-out resistance, geometry balance under hard braking

Product Segmentation for Kawasaki Partners

We’ve segmented Kawasaki suspension solutions into three key tiers: "Essential (Good)", "Performance (Better)" and "Premium (Best)". Distributors can optimize their margin and inventory with our tiered structure.

Essential (Good)

- Who it’s for: Distributors launching a Kawasaki program

- Stock first: 4–6 core movers (street fitment)

- How it makes money: high turnover + lowest claim risk

Performance (Better)

Mid-level performance solution delivering clearer feedback and stronger braking support. Designed for spirited riding on Ninja and Z platforms.

- Who it’s for: workshops and track-day dealers

- Stock first: 4–6 margin movers + 1–2 premium upsells

- How it makes money: margin pickup via “braking support + recovery” story

Competition/Race (Best)

High-spec architecture built for track conditions and maximum thermal stability. Features superior bottom-out resistance for repeat hard runs.

- Who it’s for: race shops / competition programs

- Stock first: small set + rebuild/spares policy clarified

- How it makes money: premium ASP + service ecosystem (rebuild/spares)

Core Suspension Series for Kawasaki

KRR150 Q200C

KRR150 H182B

KR150 H010D

NINJA H031

Suspension Upgrades for Kawasaki NINJA

The Limits of Stock Suspension

- Inconsistent High-Load Damping: Factory settings struggle under aggressive riding, leading to chassis vagueness and reduced lean angle confidence.

- Lack of Progressive Feedback: Limited adjustability hinders tuners from achieving ideal geometry and precise road feedback for diverse street and track conditions.

Kingham Tech Engineering Advantage

- Focused Damping Circuitry: Utilizes dedicated valving stacks for precise control over both compression and rebound, eliminating mid-corner oscillation.

- High-Precision Adjustable Components: Features micro-click adjusters on forks and shocks, providing tuners with the ability to dial in absolute chassis control for optimal track setup.

H031 RED

Performance Solutions for Kawasaki KR

Engineered to harness raw two-stroke power. This lightweight, high-revving chassis demands superior chassis support to manage its unique engine characteristics and high-speed instability. Kingham Tech transforms the KR’s raw energy into composed, controllable performance without sacrificing its aggressive agility.

Performance Deficiencies of Stock Unit

Weak Structural Support: The stock suspension often feels undersprung and harsh, failing to manage the significant power-to-weight ratio of the two-stroke engine.

High-Speed Wallow: Insufficient damping, particularly rebound, causes noticeable “wallow” and lack of composure on fast straights and sweeping corners.

Kingham Tech Engineering Advantage

Uprated Linear Spring Rates: Custom-specified spring rates provide the structural rigidity necessary to handle aggressive acceleration and braking common with two-stroke power.

Integrated Damping Circuit: Features a sealed, high-performance damping cartridge designed for consistent control over the unique chassis harmonics of the KR 150.

H010B YELLOW

H010B RED

H010B BLUE

Suspension Upgrades for Kawasaki KRR

Engineered for ultimate two-stroke competition. To fully unleash this machine's racing pedigree, the suspension must deliver top-tier stability and unyielding damping control under extreme stress. Kingham Tech provides the necessary component durability to maintain peak performance on race day.

The Limits of Stock Suspension

Rapid Thermal Degradation: Standard shocks suffer from quick heat build-up during hard use, resulting in significant damping fade and loss of stability during long runs.

Geometry Instability: Lack of precise front/rear balance leads to excessive chassis pitch and dive, hindering corner entry speed and exit traction.

Kingham Tech Engineering Advantage

High-Flow, Fade-Resistant Valving: Utilizes fluid dynamics optimized for continuous high piston velocity, guaranteeing consistent damping force regardless of component temperature.

Optimized Travel & Bottom-Out Resistance: Enhanced compression control provides firm support at the end of the stroke, maximizing ground clearance and cornering confidence.

H182B BLUE

H010B YELLOW

H010B RED

H010B BLUE

H010 YELLOW

H010 RED

Q200C GOLD

Kawasaki Starter Program

- Coverage: 3 core platforms (NINJA, KR 150, KRR 150).

- SKU Count: ~8–12 SKUs across Essential / Performance / Competition.

- Business Focus: Enough depth to build a serious program without overloading inventory.

Your Expert Partner in Suspension Manufacturing

Design & R&D

Our experienced R&D team, with over 15 years of industry expertise, develops more than 20 new products annually for our clients. Leveraging over 70 technical patents, we collaborate with customers to ensure their brands maintain sustained competitiveness in the market.

Advanced Manufacturing

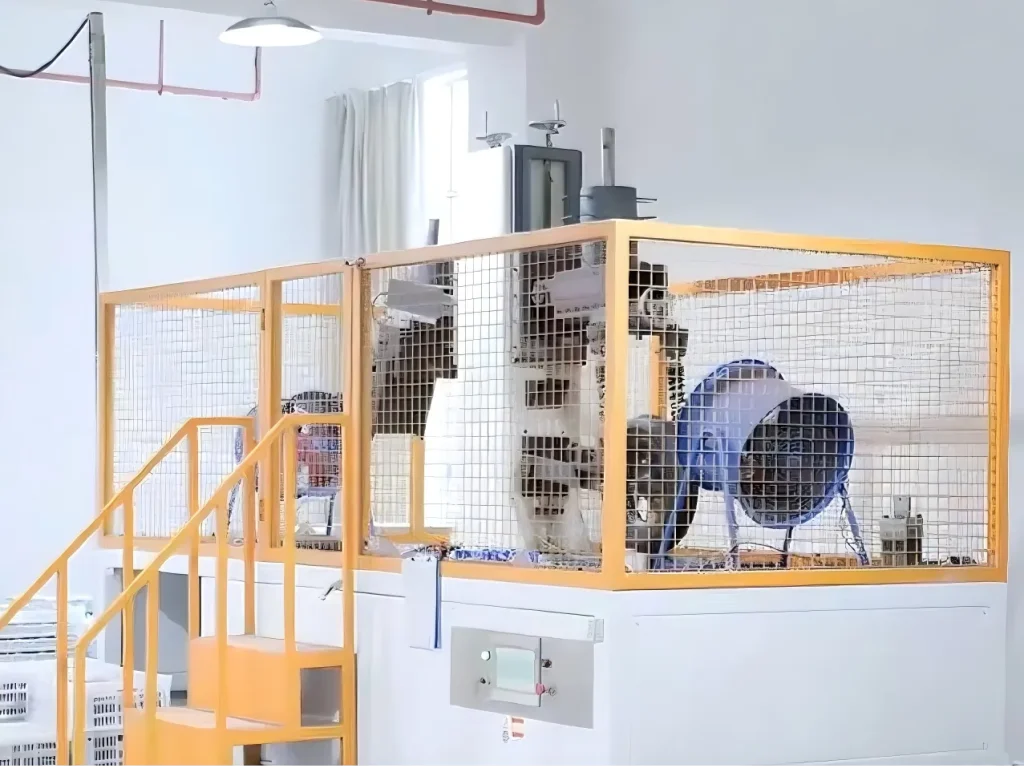

Our modern manufacturing facility spans over 16,000 square meters, equipped with more than 90 CNC precision machines and a dedicated anodizing workshop. We utilize automated assembly and testing equipment while implementing comprehensive quality inspections to ensure every product meets the highest standards.

Global Partnership

With over 7 years of ODM/OEM service experience, we have successfully served aftermarket clients across Europe, the United States, and Southeast Asia. We provide comprehensive customization services, committed to becoming your most trusted suspension system solutions provider.

Performance Validation & Reliability Metrics

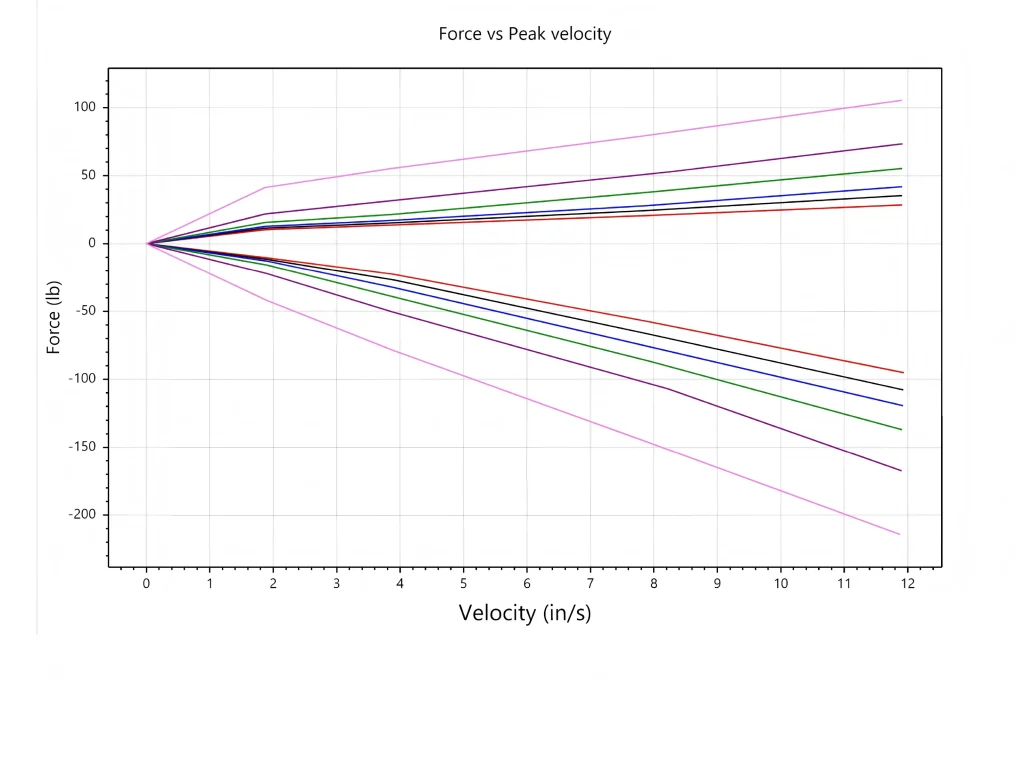

Quantified Damping Performance

This Force vs Velocity curve is the definitive proof of our performance. It confirms that our damping system maintains predictable force output and consistency, ensuring balanced and superior handling across all operating speeds.

Structural Reliability

Testing

Critical components undergo rigorous fatigue testing on specialized equipment. This protocol validates the structural integrity of our components, providing partners with confidence in the long-term durability and warranty commitment.

Production Quality & Consistency

Every unit undergoes high-speed dyno validation to verify precision before packaging. This quality control step guarantees that all production batches meet the same high standard of control and stability.

Component & Environmental Verification

We confirm material integrity and component precision using dedicated inspection equipment. All external alloys are tested for superior corrosion resistance, confirming their durability in diverse global environments.

FAQ

Can we mix multiple platforms in one order?

Do you offer private label packaging?

What is the lead time for Kawasaki suspension orders?

Can we adjust the damping settings?

Get a Kawasaki Suspension Proposal

Share details about your Kawasaki platforms. Usually reply within 1–2 days.