Kingham Factory Tour: End-to-End Suspension Manufacturing Process

From raw aluminum to finished product, our comprehensive Suspension Manufacturing Factory Tour shows how we control every step to guarantee unparalleled quality and precision.

R&D and

Engineering

A professional team with over 15 years of industry experience, dedicated to technological innovation and product development.

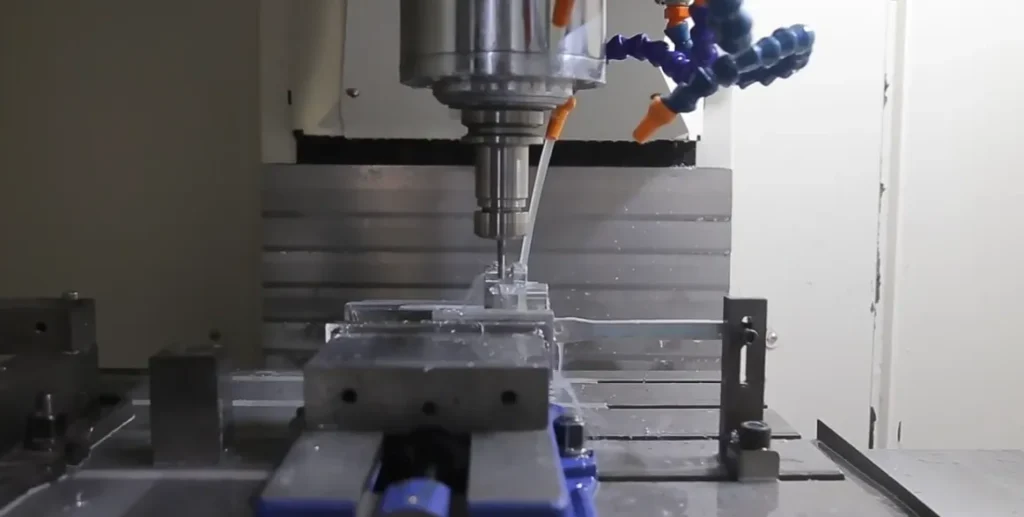

Precision CNC Machining

Over 100 state-of-the-art CNC machining centres ensure dimensional accuracy and consistency for every component.

Automated Assembly & Testing

Assembly and performance testing are conducted using automated production lines to ensure high product reliability.

In-House

Anodizing

The Cornerstone of Performance: Our CNC Department

At the heart of our manufacturing lies our CNC department, equipped with over 100 advanced machines. This large-scale precision machining capability enables us to transform the most complex designs into physical reality, ensuring exceptional dimensional accuracy and product consistency while delivering stable, reliable fulfillment for large-volume orders.

0.01mm

100%

Quality Control Throughout the Entire Process

Incoming Material Inspection

Production Process Quality Control

Perform random inspections using precision instruments such as coordinate measuring machines.

Finished Product Performance Testing

Validate extreme durability through millions of fatigue cycles.

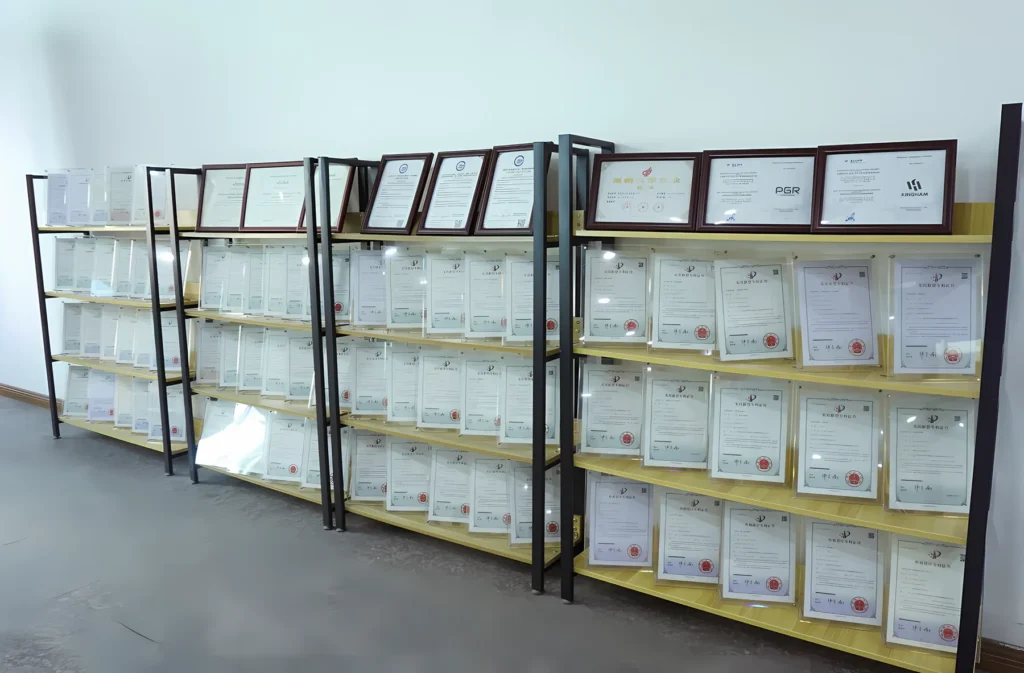

Certifications and Standards

The Fusion of Durability and Design: Our Anodizing Facility

Our dedicated in-house anodizing facility embodies our commitment to complete control over final product quality. This ensures exceptional color consistency and longevity, and significantly enhances surface hardness. For OEM/ODM clients, this means flexible, higher-quality custom color options that perfectly realize your brand’s visual identity.

The Art of the Finish: In-House Anodizing

A Meticulous Process: The Final Step

Anodizing is a specialized, meticulous process performed in our independent facility. Through precision chemical treatments in dedicated tanks, we maintain meticulous control over every step from pre-treatment to final coloring.

This controlled treatment creates a hard, nanometer-level surface, providing superior wear, corrosion resistance, and significantly improving the component’s durability and reliability. The result is a robust, high-quality finish with uniform aesthetic consistency for your final product.

Take you Closer to Kingham

Partner with a Manufacturer You Can Trust

Our factory stands as our pledge to quality. Now that you have witnessed our manufacturing capabilities, let us explore together the product lines that deliver outstanding performance for your market.