Selecting the right suppliers for brake system parts is very important. It helps keep vehicles safe and working well. Bad choices can cause big problems. Brake failure causes 22% of vehicle accidents. Also, brake problems make up 42% of all vehicle issues in crashes.

When looking at suppliers, think about important things. These include compatibility, reliability, innovation, cost, reputation, and communication. Each of these factors helps improve safety and performance. So, it is very important to choose carefully.

Key Takeaways

Pick suppliers that have a good reputation. A strong reputation shows they are reliable and provide quality parts, which are very important for safety.

Search for suppliers with experience in the industry. Experienced suppliers know brake systems well and can offer high-quality parts.

Look for important certifications like ISO 9001. These certifications mean that suppliers follow good quality management practices.

Make sure the brake parts fit your vehicle. A proper fit helps performance and keeps safety standards.

Focus on customer service and support. Good communication and warranty policies improve your experience and protect your money.

Supplier Reputation

When you check suppliers for brake parts, their reputation is very important. A good reputation usually means they are reliable and provide quality products. You want to work with suppliers who have a history of success in the industry. This can greatly affect how safe and effective your brake parts are.

Industry Experience

Experience in brake parts is important. Suppliers with many years of experience know how brake systems work. They can make high-quality parts that follow safety rules. Look for suppliers who have worked with different types of vehicles and have a wide range of products. This experience often leads to better quality and new ideas.

Kingham Technology is a great example of a trusted partner. With over 15 years in the business, Kingham has a strong reputation for making excellent motorcycle suspension and brake parts. Their deep knowledge helps them provide reliable products that improve vehicle safety and performance.

Certifications

Certifications are another important part of checking a supplier’s reputation. They show that a supplier cares about quality and follows industry rules. Look for suppliers with important certifications like ISO 9001. This means the supplier keeps high-quality management practices during production.

Also, think about certifications for specific parts. For example, brake parts should meet safety and performance rules set by authorities. This makes sure the parts you get are safe and reliable.

To help you spot possible problems with suppliers, watch for these signs that may mean a supplier is not good enough:

Decreased braking power: If the vehicle stops slower, it may mean worn parts.

Strange noises: Sounds like squeaking or grinding can mean issues with brake pads.

Soft or hard brake pedal: Changes in how the pedal feels can mean air in the lines or other problems.

Uneven or jerky stopping: This might mean alignment problems or uneven wear on parts.

Brake warning lights: Dashboard signals can mean low fluid or sensor issues.

Air leaks or hissing sounds: Constant hissing may mean air leaks, which can hurt braking.

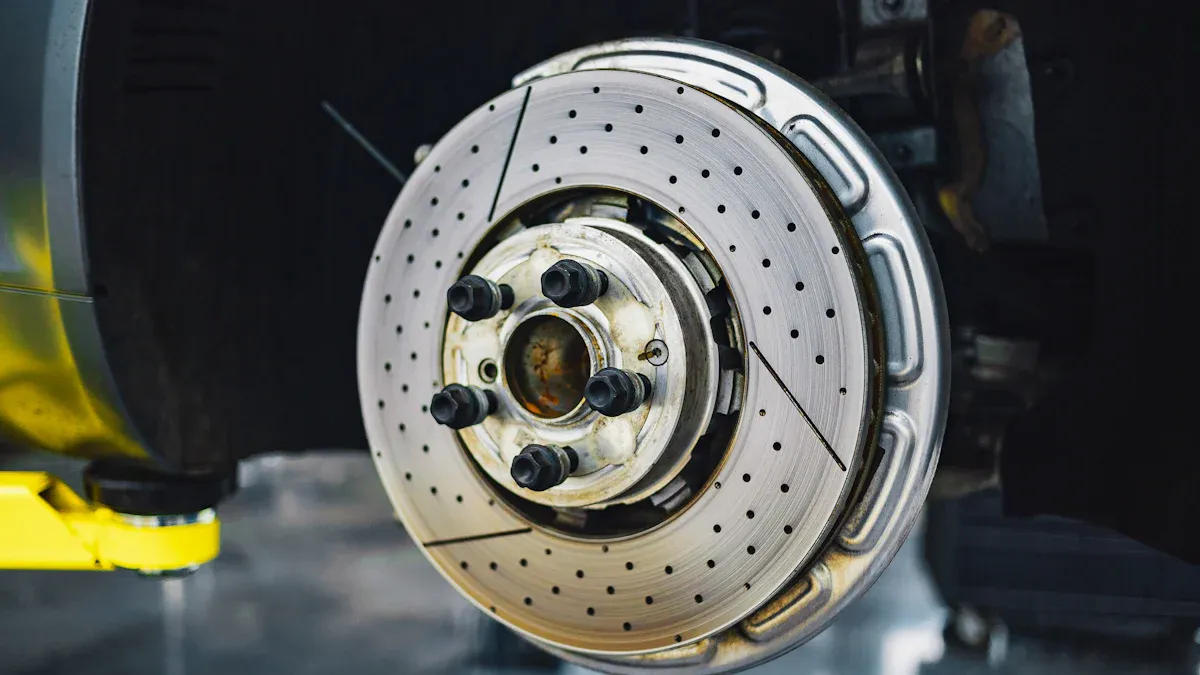

Visible damage or rust: Regular checks should find cracks, rust, or other signs of wear.

By focusing on supplier reputation, experience, and certifications, you can make smart choices when picking suppliers for your brake parts. This careful checking will help you find reliable partners who care about safety and performance.

Product Quality in Brake Systems

Product quality is very important for how well your brake system works. Good brake parts help your vehicle stop safely and effectively. When you buy quality parts, you improve your vehicle’s stopping power and safety. Bad parts can cause brake failure, which is dangerous on the road.

Material Specifications

The materials used in brake parts affect how well they work and how long they last. Here are some common materials for good brake parts:

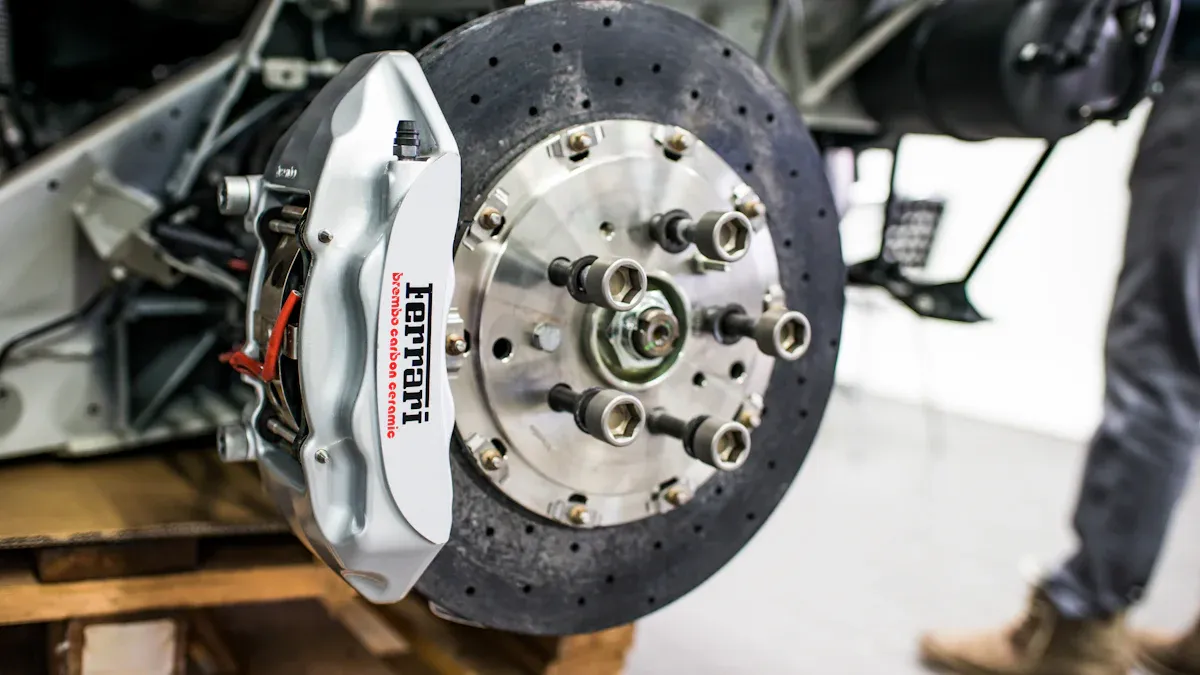

Brake calipers are usually made from aluminum or forged steel. They can also be made from cast iron or aluminum based on their functions.

Brake master cylinders often use special materials for each vehicle to improve performance. They have a smooth finish inside to help them last longer.

Choosing parts made from these materials helps them last longer and cool down better. This is important for keeping your brake system working well.

Testing Standards

To ensure safety and performance, brake parts must pass strict testing standards. Here are some important standards that manufacturers follow:

Standard | Description |

|---|---|

SAE J2975 | This defines the system for brake pad edge codes, including friction ratings. |

ECE R90 | This requires aftermarket brake pads and rotors to meet the same tests as original parts, with a performance difference of 15%. |

Groups like SAE, ECE, and ISO set tough testing rules. These tests check that brake parts meet safety needs. They look at material makeup, hardness, heat resistance, and balance.

Buying high-quality brake parts leads to better stopping power and safety. Regular maintenance with these good products helps your braking system work well. This not only improves how quickly you can stop but also reduces wear on other parts, making your vehicle last longer.

Kingham Technology shows a strong commitment to quality in brake parts. The company uses advanced CNC machines to make parts accurately. They have strict quality control systems to keep standards high during production. Kingham also does careful inspections and tests at different stages to make sure every part meets top quality standards.

By focusing on product quality, you can greatly improve your brake system’s performance and make driving safer.

Compatibility of Brake Calipers

Compatibility is very important for how well your brake system works and for safety. When you put in brake calipers, they need to fit your vehicle’s details. This helps your brakes work their best and keeps you safe. Here are some key reasons why compatibility matters:

Compatibility helps brakes work well.

It keeps safety standards, avoiding possible dangers.

Vehicle makers design brake systems with weight and heat in mind.

Vehicle Specifications

When picking brake calipers, you need to think about your vehicle’s details. This includes the make, model, and year of your motorcycle. Each vehicle has special needs that affect how the brake caliper works. For example, the caliper must fit the rotor size and type for good braking.

Cross-Referencing Parts

Kingham Technology cares about compatibility. They check that each brake caliper fits many motorcycle models by:

Matching the caliper to the vehicle (make, model, year).

Looking at important details like piston count, piston size, overall size, mounting type, rotor size and thickness, and fluid type.

Making sure it works with the current braking system, including the master cylinder and brake lines.

Kingham also checks that they follow local and global safety rules, like ECE R90 in Europe and FMVSS 135 in the US. They stick to specific car maker rules for OEM suppliers.

Also, Kingham looks at stopping power, control, heat management, and how well it resists fading when braking hard. They check data on clamping force and stiffness to make sure their brake calipers meet high standards.

By focusing on compatibility, you can improve your motorcycle’s braking power and safety. Choosing the right brake calipers makes sure your brake system works well, giving you confidence while riding.

Customer Service and Support

When you look at suppliers for brake parts, customer service is very important. Good customer support and help after the sale are key for a trustworthy brake parts maker. You want a supplier who gives technical help and installation tips. This support makes you happier and helps you fix problems after you get the parts.

Warranty Policies

Warranty policies are important when problems happen after a sale. A good warranty shows that the maker believes in their products. Here’s a quick look at how long different brake parts usually have warranties:

Component | Warranty Duration |

|---|---|

ABS Hydraulic Units | 1 Year / 18,000 Miles |

Disc Brake Calipers | 2 Years / 24,000 Miles |

Master Cylinders | 3 Years / 36,000 Miles |

Ultra Premium Calipers | 10 Years / 100,000 Miles |

These warranties give you peace of mind. They make sure you can get replacements or repairs without extra costs if something goes wrong.

Response Times

A good communication system focuses on clear answers and customer happiness. You should expect quick replies to questions and problems. Fast response times show that a supplier cares about their customers. Here are some common issues customers face with brake parts suppliers:

Modern brake systems are complex and need advanced tools.

Following strict rules means technicians need ongoing training.

Using quality parts is important for safety and performance.

Kingham Technology is great at customer support. They provide strong warranties and quick communication. Their team is ready to help you with any questions or worries. This focus on service improves your experience and builds trust in their products.

By focusing on customer service and support, you can have a better experience when choosing suppliers for your brake parts. This attention to detail helps keep your vehicle safe and working well.

In conclusion, checking suppliers for brake parts needs careful thought. Pay attention to their reputation, product quality, compatibility, and customer service. Use organized assessments and scorecards to help with your evaluations.

Here are some important points:

Key Point | Explanation |

|---|---|

Organized Assessment | A clear way to check suppliers based on quality, delivery, cost, and rules. |

Use of Scorecards | Using scorecards with KPIs for fair evaluations on a larger scale. |

Regular Evaluations | Frequent checks to find suppliers that are not doing well and improve ties. |

To make sure you evaluate thoroughly, you can:

Do regular brake checks to spot problems early.

Fix any issues like uneven brake pad wear or fluid leaks quickly.

Start a maintenance plan to keep brakes working well.

By taking these steps, you make your vehicle’s braking system safer and more reliable.

FAQ

What should I think about when picking brake parts?

You should think about compatibility, quality, and the supplier’s reputation. Make sure the parts fit your vehicle and meet safety rules. Choose suppliers with a good history in the industry.

How often should I check my brake system?

You should check your brake system at least once a year. Regular checks help find problems early, keeping your brakes safe and working well.

What are the signs that brake parts are worn out?

Signs include less stopping power, weird noises, and a soft or hard brake pedal. If you see any of these, get your brakes checked right away.

How can I make sure brake parts are good quality?

Look for suppliers with certifications like ISO 9001. Check for product testing standards and read customer reviews to see how reliable and effective they are.

Why are warranties important for brake parts?

Warranties give you peace of mind. They make sure you can get replacements or repairs if the parts break during the warranty time, protecting your investment.