Rebuildable shocks are a great choice instead of disposable ones. They lower the Total Cost of Ownership (TCO) because they last longer and can be fixed. These shocks also help with spare parts programs, making maintenance easier. Plus, flexible warranty plans make them more attractive. They give fleet managers and buyers peace of mind. Buying rebuildable shocks can save money and improve how things run.

Key Takeaways

Rebuildable shocks help save money by lasting longer and costing less to fix.

Having a good spare parts program can keep vehicles running and make work faster.

Taking care of rebuildable shocks can make them last even after the warranty ends.

Training staff to rebuild shocks and having the right tools improves repairs and lessens the need for outside help.

Different warranty choices give customers confidence, making them feel safe about their investment in rebuildable shocks.

Understanding the True Cost of Vehicle Ownership with Rebuildable Shocks

Initial Investment vs. Long-Term Value

When buying shocks, the first cost is very important. Kingham‘s front-shock-absorber and rear-shock-absorber may cost more at first than disposable ones. But they last longer and can be fixed, which makes them worth it over time.

Cost Comparison:

Kingham Front Shock Absorber: Built to last and work well, these shocks can last for years if taken care of.

Disposable Alternatives: Usually need to be replaced every few months, which adds up to higher costs later.

Buying rebuildable shocks means you replace them less often and spend less on maintenance. This choice saves money and cuts down on service delays.

Minimizing Downtime and Boosting Efficiency

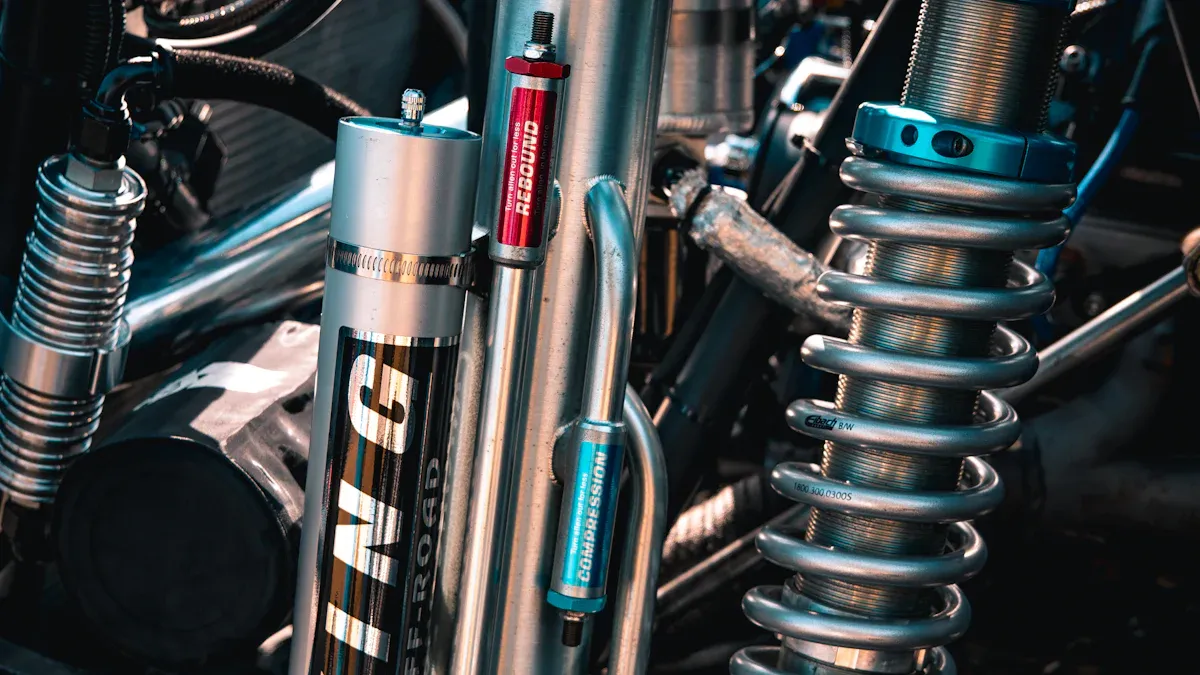

Kingham uses precise manufacturing methods, like CNC machining and automated assembly, to ensure reliable rebuilds. These modern techniques make sure each shock absorber is made to high quality standards.

Efficiency Benefits:

Quick Turnaround: Rebuilding shocks takes less time than getting and putting in new ones.

Reduced Downtime: Fleet operators can lower vehicle downtime, keeping things running smoothly.

By choosing rebuildable shocks, businesses can work more efficiently. The ability to quickly rebuild and use shocks again leads to more productivity and lower costs.

Sustainability and Environmental Impact

The effect of vehicle parts on the environment is becoming more important. Rebuilding Kingham’s products instead of throwing them away has big ecological benefits.

Sustainability Factors:

Waste Reduction: Rebuildable shocks create less waste from old parts.

Resource Conservation: Making new shocks uses energy and materials. Rebuilding uses what is already there, saving resources.

By choosing rebuildable shocks, companies save money and help the environment. This choice fits with the growing focus on being responsible in the automotive industry.

Building an Effective Spares Program for Rebuildable Shocks

Key Components for Spares Inventory

A good spares program for rebuildable shocks needs careful choice of important parts. For Kingham’s front-shock-absorber and rear-shock-absorber, these parts should be kept in stock for quick rebuilds:

Seals

Oil

Shims

Shafts

These parts are very important for keeping the shock absorbers working well. By having these key parts ready, fleet managers can reduce downtime and make rebuilding easier.

Inventory Management Strategies

Using strong inventory management strategies is important for tracking rebuildable shock parts. Using special inventory software can really help with efficiency. The table below shows the benefits of good inventory management:

Benefit | Description |

|---|---|

Cost Savings | Reduces extra purchases by tracking parts in stock, cutting down on overstocking or running out. |

Improved Efficiency | Automates inventory tasks, letting fleet managers focus on important work. |

Reduced Downtime | Makes sure key parts are ready, leading to faster repairs and less delay. |

Enhanced Accuracy | Increases accuracy in tracking, helping with better decisions and planning. |

Better Resource Management | Gives insights into parts use for smart resource allocation. |

By using these strategies, businesses can keep the right inventory levels, making sure they have the parts needed for quick rebuilds.

In-House Rebuild Training and Tools

Setting up in-house rebuilding skills has many benefits. It helps teams fix things quickly and well, reducing the need for outside help. To do this, companies should buy important tools and equipment for rebuilding Kingham’s shocks. Here’s a list of what is needed:

Spanner Wrench

High Quality Snap Ring Pliers

Safety Glasses and Gloves

Shop Rags and Paper Towels

Nitrogen Fill Kit

Pressure Gauge

Piston Bleed Screws

Schrader Valve Caps and Cores

Valve Core Tool

Abrasive Blocks (Emery Sticks)

Loctite / Threadlocker

IFP Setting Tool

Bearing Lubricant

24″ Adjustable Wrench

Propane Torch

Penetrant and Lubricant

Caliper

Preload Pin / Punch

1/2″ Heat Shrink

Training workers on how to use these tools helps them rebuild shocks well, keeping the high quality of Kingham’s products. This investment in skills and tools not only improves efficiency but also helps the spares program succeed.

Optimizing Warranty Strategies for Rebuildable Shocks

Manufacturer Warranty Coverage

It is important for fleet managers to know about warranty coverage for rebuildable shocks. Usually, manufacturers give warranties that cover problems with materials or how they are made. The length and details can change by brand. The table below shows common warranty terms for different manufacturers:

Manufacturer | Warranty Duration | Covered Components |

|---|---|---|

Arnott | Limited 2-Year | Problems with materials or workmanship |

Monroe | Limited Lifetime | Problems with materials or workmanship |

KYB | Limited Lifetime | Problems with materials or workmanship |

Eibach | Limited Lifetime | Problems with materials or workmanship |

Tokico | 3 Years | Problems with materials or workmanship |

Rancho | Limited Lifetime | Problems with materials or workmanship |

These warranties usually do not cover damage from misuse, changes, or not keeping up with maintenance.

Rebuilt Component Warranty

Kingham gives warranties for rebuilt shock parts. This ensures customers get good service. The main points include:

Warranty period: 90 days from the purchase date

Coverage: Manufacturing defects

Exclusions: Crash damage, abuse, changes, using non-Kingham parts, not maintaining, and wrong specs on custom orders.

This warranty setup helps customers feel secure about their choice in rebuildable shocks.

Extending Shock Life Post-Warranty

To make Kingham’s front-shock-absorber and rear-shock-absorber last longer after the warranty ends, regular maintenance is very important. Recommended practices include:

Check for oil leaks often

Listen for strange noises

Watch for too much body movement

Also, do not remanufacture shock absorbers. This can cause sealing and alignment issues. Be careful, as remanufactured absorbers might squeak or knock. Following these tips can greatly increase the life of rebuildable shocks.

Rebuildable shocks are a smart investment that helps lower total costs. They make maintenance easier with good spare parts programs and strong warranty options. By using these benefits, businesses can work better and save money over time.

As the car industry changes, rebuildable shocks will change too. We can expect them to work well with self-driving cars, use advanced AI, and focus on being eco-friendly. These trends will keep rebuildable shocks a good choice for people who want strength and performance in tough situations.

FAQ

What are rebuildable shocks?

Rebuildable shocks are parts of the suspension that can be used many times. They can be taken apart, fixed, and put back together. This makes them last longer than disposable shocks.

How often should I rebuild my shocks?

How often you rebuild your shocks depends on how you use them and the conditions. Usually, check your shocks every 10,000 miles or after big bumps. Regular checks help keep them working well.

Can I rebuild shocks myself?

Yes, if you have the right tools and training, you can rebuild shocks. But getting help from a professional can make sure the work is done well.

What parts are typically replaced during a rebuild?

Parts that are often replaced include seals, oil, shims, and shafts. These parts are important for keeping the shocks working well and lasting longer.

Do rebuildable shocks come with a warranty?

Yes, Kingham gives warranties on rebuildable shocks. This usually covers problems from manufacturing, which helps users feel secure.