Shock absorber housings are critical components that significantly influence vehicle performance and safety. This blog explores two primary manufacturing methods: CNC machining of 7075 aluminum and traditional casting. We will compare these techniques to understand their impact on part accuracy and strength, which directly affects the overall functionality and lifespan of shock absorbers. CNC machining with 7075 aluminum offers superior precision & durability due to its advanced material properties and manufacturing process, resulting in highly accurate and robust components.

Key Takeaways

CNC machining with 7075 aluminum makes shock parts very exact. This helps shocks work better and last longer.

7075 aluminum is a strong material. It helps shock parts handle tough use and resist breaking over time.

CNC machined parts are smoother and stronger than cast parts. This means better performance and a longer life for your shocks.

Even though CNC 7075 parts cost more at first, they save money later. They need fewer repairs and make your ride better for a long time.

Manufacturing Processes Compared

This part looks at how CNC 7075 housings and cast parts are made. Knowing these ways helps explain their good and bad points.

CNC Machining 7075 Aluminum

CNC machining cuts material away. It begins with a solid block. This is often 7075 aluminum. Machines then cut it to shape. This way is very exact. It makes parts fit well. 7075 aluminum is strong. It is used in airplanes. It is light but very tough. It resists getting tired. These things make parts precise and strong. Kingham uses good CNC machines. They cut with 0.01mm accuracy. All key parts are CNC-made. For 7075-T6 aluminum, machines can cut to ±0.005mm. This is very precise. It is important for shock parts.

CNC machining keeps diameters exact. They are within ±0.01mm. It also keeps parts centered. This is within 0.02mm TIR. End faces are straight. They are within 0.015mm.

Casting Processes Explained

Casting adds material. Hot metal is poured into a mold. It cools and gets hard. This makes the shape. Shocks often use aluminum or iron. But casting has problems. It can make small holes. These are called porosity. The metal’s inside can be uneven. This makes the material weaker. Cast parts are less exact. They are not as precise as machined parts. They can have hidden flaws. These flaws can make parts break. They also hurt how parts work.

Precision: A Key Difference

How things are made changes how exact and smooth shock parts are. These things are very important for shocks to work well.

Exact Size & Limits

CNC machining controls sizes better. This means parts fit together very well. This is key for steady valving. It lowers rubbing. It helps seals work better. It also makes damping better. CNC machining makes things very exact.

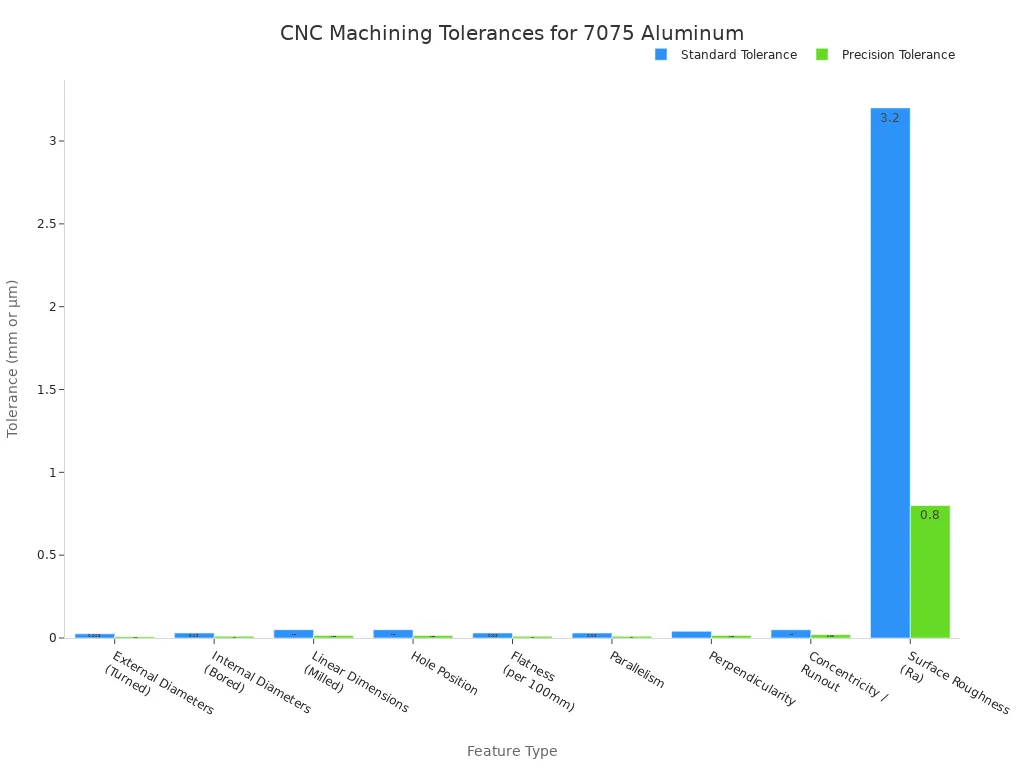

Here is how exact things can be:

Factor | Casting Limits | Machining Limits |

|---|---|---|

General | Often not as exact (±0.1 mm or more) | Very exact (up to ±0.0002″) |

Precision Machining (CNC) | Not used here | Usually ±0.025 mm, can be more exact |

For shock parts, CNC machining is much more exact than casting. Casting is usually off by about ±0.1 mm for every 25 mm. Precision machining with CNC can be as close as ±0.025 mm. It can be even closer with special tools. This exactness is needed for parts that must fit perfectly. Casting cannot do this.

Exact sizes in shock parts are key for steady valving. They are also key for how fluid moves. They stop fluid from leaking inside.

Michael O’Callaghan warns about buying cheap shocks. He says, ‘Cheap performance shocks can be very uneven in how they damp. You will easily feel this.’

Expensive shocks are “made with more care to tighter limits.” This makes them cost more to make. Cheap shocks use “helpful leaks inside from using cheaper parts.” This means they do not need to be as exact. This makes damping softer. Exact making directly affects how fluid flows. It stops unwanted leaks. This is key for steady work.

Expensive shocks are known for being “made with more care to tighter limits.” They also have bigger shafts, pistons, and valve stacks. This careful making helps valving stay steady. It also helps fluid move well. It stops leaks inside. This is why they cost more. A small gap on a Force vs. Velocity graph shows a “well-made shock.” It has steady valving and fluid flow. “Odd Force vs. Velocity graphs” can “hide problems inside the shock.” This means it is not made well. This is often due to loose limits. It makes things less steady and fluid harder to control.

Smoothness & Inside Shape

CNC machined parts are very smooth. This smooth surface makes parts last longer. It also helps seals last longer.

Good shaft surfaces are key for seals to work best. Smooth or ground shafts with round marks seal best. These shafts do not have a spiral line. If there are spiral lines, they should point to the fluid as the shaft turns. This keeps the seal working. Making shaft surfaces very good is key for great sealing. How spiral lines and tool marks look and point greatly affects how well a seal works. For the best seal, shafts should be smooth or ground. They should have round marks. This avoids any spiral line. If spiral lines must be there, they must line up with the fluid flow when the shaft turns.

CNC machining can make complex and exact inside shapes. These are vital for how fluid moves and valving in shocks. Casting finds it hard or impossible to make such complex shapes. Being able to machine these complex inside parts very exactly helps a lot with the overall Precision & Durability of the shock.

Durability: Withstanding Rigors

This part looks at how strong materials are. It checks how well they handle daily use. It also checks tough conditions.

Material Strength & Fatigue Resistance

7075 aluminum is very strong. It fights fatigue well. Fatigue means it gets weak over time. This is from stress again and again. CNC machining keeps the material’s natural grain. This makes the part stronger. Cast materials are often weaker. They break down faster from fatigue. This is because they can have small flaws inside. Their grain is also less even.

Impact Resistance & Structural Integrity

CNC 7075 is solid and even. This helps it handle impacts well. It keeps its shape and strength. Cast parts are often not as strong. They can have small holes. Or they can have uneven spots. These weak spots make them crack easier. This happens under stress. CNC 7075 has a steady structure. This gives it better overall strength.

Corrosion Resistance

7075 aluminum fights rust. CNC machining does not hurt this. Some casting can make parts rust easier. But 7075 aluminum rusts easier. This is compared to other aluminum types. This is true in wet or salty places. Its copper makes it rust more.

To fix this, makers use special steps. Kingham uses its own anodizing place. This makes the surface harder. It also helps it last longer. It stops rust for their front-shock parts. Anodizing makes a strong layer. This layer makes 7075 aluminum resist rust much more. It works well in tough places. This includes ocean areas.

Type III black anodizing is key for shock parts. It makes a thick, hard coat. This coat is 25-100 micrometers thick. It makes the surface hardness 400-600 HV. This protects almost like ceramic. It is vital for extreme wear. It helps with harsh rubbing. It also helps with chemicals. It handles heat up to 200°C. It does not break down. This top durability and hardness are key. This is for high-stress parts. Shock parts are an example. This process makes parts precise and durable.

Performance: How Exactness & Strength Help

This part shows how good CNC 7075 parts help shocks work better. It means a better ride.

Steady Damping & Ride Feel

CNC 7075 parts are very exact and strong. This makes shocks damp steadily. They also cool down better. Riders get a ride that feels the same and is good. Kingham’s front shocks can be set in two or three ways. This helps with comfort and steadiness. Good shocks make the ride much better. Changing springs and dampers can make rides 7% more comfy. Riders also get 20% better road grip. This makes bikes handle better and feel safer.

Long Life & Trustworthiness

Shocks with CNC 7075 parts last longer. They also break down less often. This is because they wear out less. They handle tough use better. Parts last longer. For example, suspension parts can last 30% longer. This means less fixing is needed. They work well for many years. Strong CNC 7075 parts handle hard places. They are a good choice for any rider.

Cost vs. Value: Making the Choice

Initial Cost Considerations

CNC 7075 parts cost more at first. The making process is hard. It needs special tools. It needs trained workers. 7075 aluminum also costs more. This is true compared to other metals. These things make the price higher. Buyers see this right away.

Long-Term Value & Performance

CNC 7075 parts are more exact. They last longer. They work better. This makes the higher cost worth it. These parts give good value over time. They need less care. They last longer. This means fewer new parts are needed. The user also has a better time. Shocks with CNC 7075 parts damp steadily. They work well for many years. This saves money in the long run.

For example, Kingham uses good CNC machines. This is for its 7075 parts. This makes sure they are very good. They care about exact making. This means buyers get strong and true parts. This makes them more trusted. It also gives a smoother ride. Putting money into CNC 7075, like Kingham does, pays off. It gives peace of mind. It gives top performance. This makes it a smart pick for smart riders.

CNC 7075 housings are better. They offer more precision & durability. This is true for shock absorbers. They are better than cast parts. The way they are made is advanced. 7075 aluminum is a strong material. It makes parts very exact. They are also stronger. They work better. They last longer. Cast parts cost less at first. But CNC 7075 housings are worth the money. They save money later. They need less fixing. They make riding better. Kingham uses good CNC machining. This is for its 7075 parts. This makes sure they are top quality. They care about new ideas. They care about good quality. This shows why these materials and methods are key. This is for motorcycle shocks.

FAQ

Why is CNC 7075 aluminum better than cast parts for shocks?

CNC 7075 aluminum is more exact. It lasts longer. It has a strong, even build. This material fights wear better. Cast parts often have flaws. Their strength is not steady. So, CNC 7075 is a better choice for shocks.

How does exactness change how shocks work?

Exactness makes damping steady. It helps fluid flow better. Small gaps mean less rubbing. Seals work better. This makes the ride smoother. It also helps the shock work best always.

Why is 7075 aluminum strong for shocks?

7075 aluminum is used in planes. It is strong but light. It fights wear very well. CNC machining keeps its strong grain. This makes parts tough. They last long, even in hard use.

Does Kingham use CNC machining for its shock parts?

Yes, Kingham uses good CNC machines. This is for its main shock parts. This makes them very exact and good. Kingham’s 7075 parts are great. This is because of this tech. They meet tight 0.01mm limits. This promise gives great work and trust.