Brake parts play a crucial role in vehicle safety and performance, with an alarming 22% of vehicle accidents attributed to brake failures. This statistic underscores their critical importance.

Failure Type | Percentage of Accidents |

|---|---|

Brake Failures | 22% |

The OEM procurement process for these parts involves navigating complex supply chains while ensuring adherence to stringent quality standards. Challenges such as supply chain disruptions and rising material costs often complicate the procurement of these essential components.

Key Takeaways

Brake parts are very important for vehicle safety. Bad quality can cause serious accidents.

Use a clear process for buying: check needs, choose suppliers, and make sure to check quality.

Supply chain problems can happen due to natural disasters, political issues, and money problems. Use different suppliers to reduce risks.

Keep up with changing rules to avoid legal problems and keep product quality high.

Increasing material costs need careful budgeting and smart buying plans to stay profitable.

Essential Brake Components

Types of Brake Components

When you think about brake components, several important parts come to mind. These include:

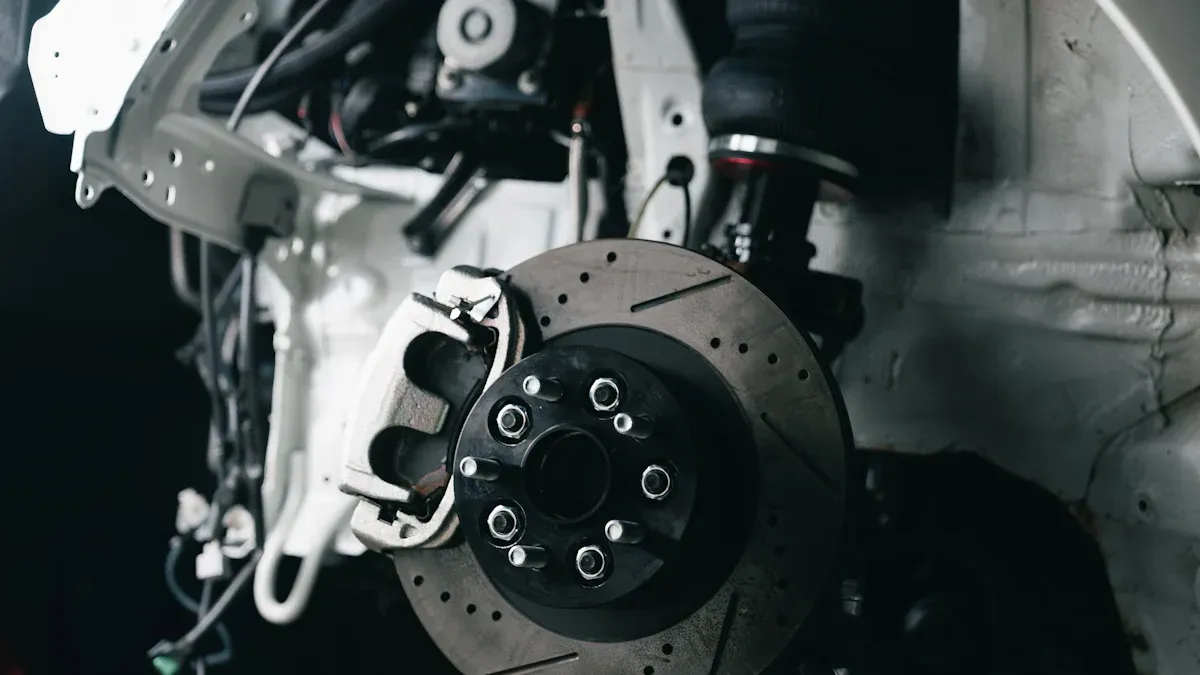

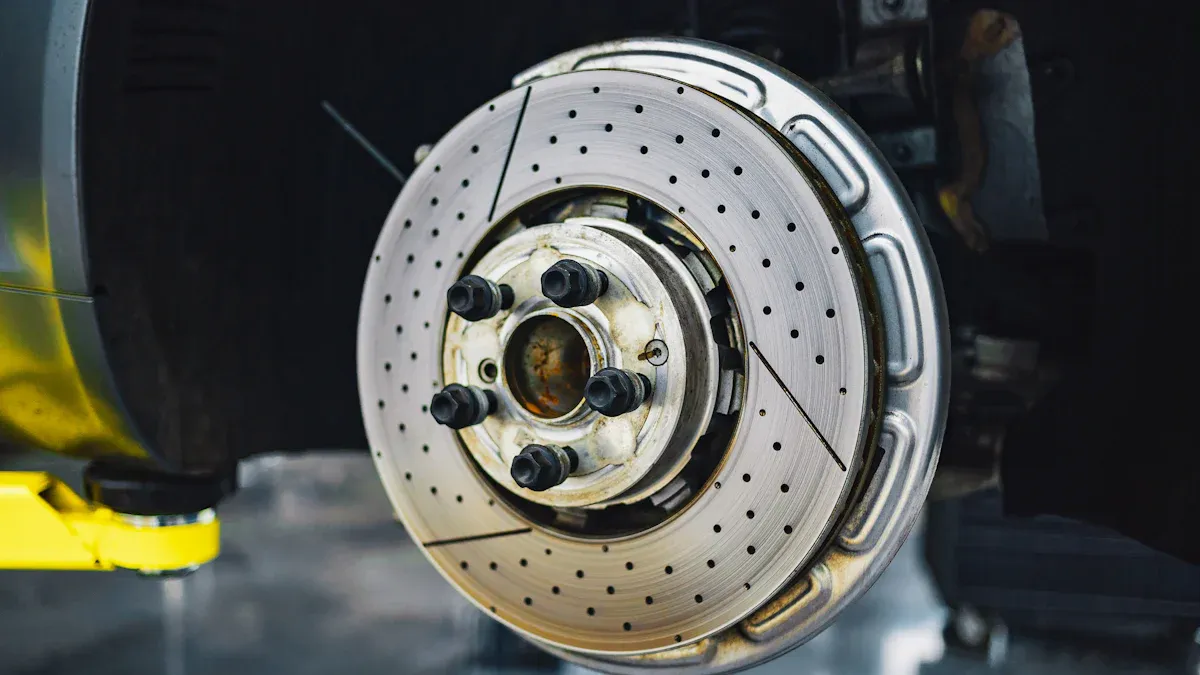

Disc Brakes: These are popular because they stop quickly. They work well in heavy-duty situations. They stay cooler than drum brakes, making them great for fast cars.

Drum Brakes: These are not as common today, but they are still liked. They are cheaper and last longer, especially for the back wheels.

Brake Pads: There are many types available. Non-Asbestos Organic pads are the most popular because they are safe and good for the environment. Other types are Semi-Metallic and Ceramic pads, each with their own strengths.

Calipers: These parts hold the brake pads and push on the brake discs. They are very important for stopping the vehicle.

Importance of Quality

The quality of brake components is very important for vehicle safety. Bad parts can cause serious accidents. Here are some reasons why quality matters:

Brake Pad Functionality | Safety Implications |

|---|---|

Energy Absorption | This is key for slowing down; bad parts can cause crashes. |

Heat Generation | It needs to be controlled to stop overheating and failures. |

Material Selection | This affects how fast parts wear out and how well they stop, which is vital for safety. |

Good-quality brake components make sure your vehicle works well in different situations. They keep a steady level of friction, which is needed for stopping. When you pick parts that follow OEM standards, you make your vehicle safer and better. Choosing quality brake parts not only keeps you safe but also helps your braking system last longer.

OEM Procurement Process

Steps in Procurement

The OEM procurement process for brake parts has several important steps. You need to follow these steps for a smooth and effective process:

Needs Assessment: Find out which brake parts you need for your vehicles. This means knowing the performance needs and safety rules.

Supplier Selection: Look for suppliers who can meet your quality and delivery needs. Check their skills and past work.

Request for Quotation (RFQ): Send RFQs to chosen suppliers. This document explains what you need and asks for prices and delivery times.

Evaluation of Proposals: Look at the proposals you get. Compare prices, quality checks, and delivery times.

Negotiation: Talk with suppliers to agree on terms. Try to balance cost and quality.

Order Placement: After negotiations, place the order with the selected supplier. Make sure all details are clear.

Quality Assurance: Do strict quality checks at every step of the procurement process. This is very important because each part could fail.

Key Stakeholders

Many key people are important in the OEM procurement process. These include:

Procurement Team: They find and negotiate with suppliers. They make sure the procurement meets company standards.

Quality Assurance Team: This team checks the quality of parts. They review how parts are made and ensure they meet OEM standards.

Engineering Team: They give technical details and check if parts work with current systems.

Suppliers: They are important for delivering the needed parts on time and meeting quality standards.

A smart approach to checking quality helps keep operations running well and safe. Move from focusing only on price to a full quality check system. Look at material science, how parts are made, and if they follow global quality rules. This method lowers Total Cost of Ownership (TCO) by cutting down on downtime and major failures.

Challenges in OEM Procurement

Supply Chain Disruptions

OEMs face big problems when getting brake parts due to supply chain disruptions. These problems can happen because of different reasons, like:

Natural disasters: Things like floods and earthquakes can stop work and make raw materials hard to get.

Geopolitical issues and trade policies: Wars or tariffs can mess up the worldwide flow of goods.

Supplier financial difficulties: Money troubles anywhere in the supply chain can cause delays and raise costs.

Cyberattacks: These attacks can mess up logistics and steal important info, causing delays.

Pandemics and health crises: Health problems can stop production and transport, hurting supply chains.

These supply chain problems can cause money risks, process risks, and legal risks. You need to know about these risks to lessen their effect on your buying plans.

To fix these problems, try using different suppliers. This plan makes sure you have backup sources for important parts. Also, keeping extra stock of risky parts can help keep things running without using too much money.

Regulatory Compliance

Following rules makes the OEM buying process harder. You have to deal with different rules that change a lot between places. Here are some main problems with following rules:

Challenge | Description |

|---|---|

Different places have their own safety rules, making it harder and costlier for makers. | |

Evolving Standards | Rules keep changing, needing more spending on research and getting certified. |

Certification Processes | Tough testing and paperwork are needed to follow rules, which takes a lot of resources. |

Environmental Regulations | Rules affect what materials you use and how you make things, adding more rules to follow. |

These problems can stretch your budget and resources. You need to focus on being strong and saving money while keeping up with changing rules. Focusing on being green and energy-saving can also make your buying plans better.

Rising Material Costs

Rising material costs are a big worry for OEMs in the car industry. In the past five years, these costs have really hit buying budgets. Here are some important things to think about:

Rising material costs put more pressure on OEMs’ money plans and choices.

OEMs deal with higher prices and less productivity because EMS providers choose more profitable deals.

Higher borrowing costs make it hard for OEMs to fund big projects, making money planning tricky.

As you deal with these rising costs, think about adding smart buffers in your buying process. This way, you stay ready and efficient, managing costs without losing quality.

Solutions for OEMs

Kingham’s OEM/ODM Solutions

Kingham Technology provides smart solutions for OEMs in the car industry. Our OEM/ODM services let you customize brake parts to fit your needs and performance goals. Here’s how we can assist you:

Comprehensive Development Process: We handle every step from idea to mass production. This makes sure each part meets your exact engineering needs.

Advanced Manufacturing Facilities: Our modern facility has over 100 CNC machines. This helps us make high-quality brake parts quickly.

Rapid Prototyping: We use advanced 3D modeling and quick prototyping to check designs fast. This cuts down lead times and speeds up your market entry.

Collaborative Partnerships: We build strong partnerships with our clients. This helps us understand your needs and adjust our solutions as needed.

By using these skills, you can improve your products and stay competitive in the market.

Quality Control Measures

Quality control is very important when buying brake parts. At Kingham, we have strict quality checks to ensure safety and reliability. Here are some key practices we follow:

Testing Protocols: We do thorough tests for heat handling and performance under pressure. This includes:

Checking for leaks and seals in rotors, pads, calipers, and lines.

Lab tests for thermal, friction, wear, and endurance.

NVH (Noise, Vibration, Harshness) and fit checks to ensure quiet operation and compatibility.

Real-World Validation: We conduct field tests, including vehicle tests and fleet trials, to confirm how our parts perform in real-life situations.

Quality Management Systems: Our processes follow IATF 16949 and ISO 9001 standards. This ensures we keep high quality during production.

Continuous Improvement: We welcome new ideas in our manufacturing. For example, we use just-in-time (JIT) inventory to lower storage costs while keeping enough stock. We also use digital tools like blockchain to improve supply chain visibility, allowing real-time tracking of parts.

By focusing on quality control and innovation, you can reduce risks from poor parts and quality differences. This commitment not only boosts the reliability of your brake components but also helps with cost management and efficiency.

In conclusion, you have some big challenges when buying brake parts. Problems like supply chain issues, following rules, and rising material costs can slow you down. To deal with these problems, think about using solutions like finding different suppliers and using digital tools.

Keep in mind, more than 65% of companies are using AI and IoT tools to make their supply chains better. This shows how important it is to be active in your buying plans.

Always check and change your methods to stay strong in the changing car industry. By doing this, you can stay ahead of the competition and meet your customers’ needs well.

FAQ

What are the key factors to consider when selecting brake components?

You should think about quality, fit, and how well they work. Make sure the parts meet industry rules and match your vehicle’s needs. Good quality parts make your vehicle safer and last longer.

How can you manage supply chain disruptions in the automotive industry?

Use different suppliers and keep extra stock of important parts. This plan helps reduce risks and makes sure you have the parts you need.

Why is regulatory compliance crucial in the automotive industry?

Following rules keeps things safe and high quality. It helps you avoid legal problems and keeps your good name. Staying updated with changing rules is key for doing well.

How do rising material costs affect the automotive industry?

Higher costs affect budgets and pricing plans. You need to improve buying processes and look for cheaper options to stay profitable.

What role does quality control play in the procurement process?

Quality control makes sure parts meet safety and performance rules. It lowers the chance of failures and makes customers happier.