In your work on front suspension OEM/ODM projects, understanding the sample, validation, and PPAP timeline is very important. These parts help make sure that car parts are good quality and reliable. Teaming up with a Chinese partner can help you learn more about these steps. Their knowledge can make production easier, lower costs, and boost efficiency. By paying attention to these timelines, you can match your goals with what your partner can do. This leads to better project results.

Key Takeaways

Know the difference between OEM and ODM. OEM lets you customize a lot, while ODM uses existing designs with few changes.

Keep up with market trends in suspension systems. This helps you make smart choices and adjust to changes in the industry.

Follow strict validation steps. Make sure all parts are safe and work well to avoid expensive recalls and improve reliability.

Talk clearly with Chinese partners. Regular updates and open talks can stop misunderstandings and make projects better.

Build strong relationships based on trust and respect. Knowing cultural differences can help teamwork and lead to successful partnerships.

Overview of OEM/ODM Projects

OEM vs. ODM

In the car industry, you will see two terms: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). Knowing the differences between these two is important for your projects.

Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

Design Control | High; buyer gives design, OEM makes it | Low; ODM designs and makes, buyer can change a little |

Intellectual Property Ownership | Buyer keeps ownership of IP | Supplier usually keeps ownership of IP |

Customization Levels | High; lots of customization possible | Limited; mostly small changes allowed |

Time to Market | Longer; needs full design and testing | Shorter; uses existing designs and tests |

Investment Profiles | Higher upfront cost for research and tools | Lower upfront cost; costs shared with many clients |

The OEM model allows for a lot of customization. You can choose every part and material, which is important for products needing special performance. On the other hand, the ODM model focuses on small changes, limiting your ability to make big changes without extra costs.

Market Trends in Suspension Systems

The car suspension market is changing fast. Here are some key trends affecting the industry:

The market is growing because of new technology and more cars being made.

There is a higher demand for electric and hybrid cars, which need special suspension systems.

Advanced systems like adaptive and active suspensions are being used to improve ride comfort and handling.

The Asia-Pacific area is leading the market because of its factories and more people owning cars.

You should also know about the challenges. High costs of new technologies and supply chain issues can affect your projects. The move towards advanced and lighter suspension systems is important to meet safety rules. Also, using IoT sensors and vehicle control modules is becoming common in luxury and self-driving cars.

As you work in the OEM/ODM world, keeping up with these trends will help you make better choices for your projects.

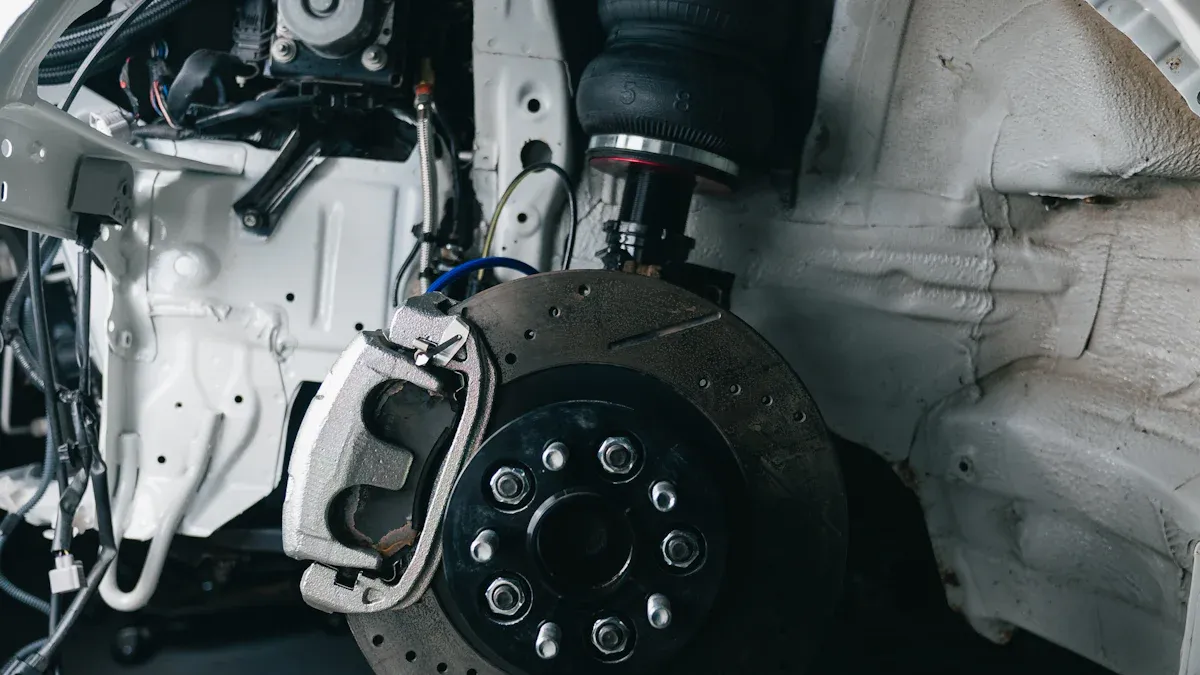

Sample Development in Suspension Projects

Initial Design and Prototyping

The sample development process for front suspension parts has several important steps. You begin with the initial design and prototyping. This is very important to make sure the parts are safe and work well. Here are some good methods used in this stage:

Methodology | Description |

|---|---|

Use CAD software to create models of front and rear suspension systems, keeping vehicle limits in mind. | |

Finite Element Analysis (FEA) | Use FEA to find out stresses and changes in the suspension parts. |

Simulation | Run simulations in software like ADAMS to see how the suspension system works. |

Chinese manufacturers often focus on making prototypes and testing them in-house. For example, companies like SYM offer many prototyping services. This helps car makers test and improve their designs before starting full production. These practices help speed up development and fix problems early.

Material Selection and Sourcing

Choosing materials is very important for how well suspension parts work and last. You must pick materials that can handle different stresses while being lightweight. Common materials for front suspension parts include:

Component Type | Material |

|---|---|

Alloy Steel | |

Shock Absorber Linkage | Aluminum (AL 6061-T6, 6063, 7075-T, etc.) |

When getting materials, think about cost, availability, and how well they perform. Kingham Technology focuses on finding high-quality materials that improve their suspension systems. By using their wide network of suppliers, they make sure each part meets the needed strength and durability standards.

Validation Procedures for Automotive Components

Validation is very important in OEM/ODM projects. This is especially true for car parts like front suspension systems. You need to make sure every part meets strict safety and performance rules. This process helps you avoid expensive recalls and makes your products more reliable.

Quality Assurance Standards

To keep high-quality standards, you should follow set guidelines. Many Chinese manufacturers follow international quality assurance standards. Here are some key practices:

Manufacturers check ISO 9001 certification as a starting point for process control.

Following IATF 16949 is important for suppliers aiming at North American or European markets.

The documents needed include:

Material traceability (like steel batch numbers)

Hardness testing reports for forged parts

Fatigue cycle test results for load-bearing parts

Bushing durability data under stress conditions.

For example, Guangdong Tenneco has a strict quality management system. They do many quality checks during production. Similarly, Tiroflx follows ISO/TS 16949, CE, and E-mark standards, checking quality throughout production.

Testing Methods and Protocols

You can use different testing methods to check front suspension parts effectively. Each method has a specific purpose to ensure the quality and performance of the parts. Here are some common testing procedures:

Testing Procedure | Description |

|---|---|

X-ray inspection | For BGA, QFN, and hidden joints |

Electrical tests | Flying probe or ICT for open and short detection |

Functional tests | For mission-critical products |

Fatigue and performance testing | Needed for thorough validation |

Different project types may need different validation focuses. For example:

Project Type | Validation Focus |

|---|---|

ODM | Extra validation at the prototype stage |

OEM | Focus on keeping stable yields and repeatability |

Using these testing methods in your validation process helps ensure your suspension parts meet high quality and performance standards. By focusing on thorough testing, you make your products more reliable and build trust with your clients.

PPAP Requirements and Timeline

Understanding PPAP

The Production Part Approval Process (PPAP) is very important in the car industry. It makes sure that parts meet design rules and quality checks. This process shows that your ways of making parts are good and can produce them the same way every time. Here are some main benefits of the PPAP process:

It lowers the chance of mistakes.

It builds better relationships between suppliers and customers.

It improves openness and responsibility.

The PPAP process needs a clear submission of proof, like design papers, control plans, and early process studies. This paperwork helps you make sure that your suspension parts will work well.

Timeline for PPAP Submission

The timeline for PPAP submission can change based on how complex the project is. But, you can usually expect these steps:

Initial Design Review: Check the design and collect needed documents.

Prototype Development: Make prototypes for testing and checking.

Testing and Validation: Do tests to confirm parts meet rules.

Documentation Preparation: Gather all needed papers, including:

Control Plans

Dimensional Results

Chinese manufacturers often have problems with PPAP paperwork and submission. They need to make sure that all parts, like design papers and measurement system checks, are finished. By following the PPAP rules, they can keep quality steady and cut down on rework. This carefulness helps build trust with clients and makes sure that the final products meet high standards.

Best Practices for Working with Chinese Partners

Communication Strategies

Good communication is very important when working with suppliers in China. Here are some ways to improve teamwork:

Strategy | Description |

|---|---|

Set up regular updates to talk about progress and keep everyone informed. Make sure to assign clear communication tasks to avoid confusion. | |

Open Communication | Encourage feedback from both sides to ensure everyone is on the same page and can quickly solve problems. |

Consider Time Differences | Find overlapping work hours and use apps like WeChat for faster communication. |

Simplified Language | Use simple words and break down complex projects into easy parts to prevent misunderstandings. |

Keeping close communication helps you solve problems early. Regularly checking progress lets you spot delays quickly and adjust to surprises.

Cultural Considerations

Knowing cultural differences can greatly improve your partnership with Chinese manufacturers. Here are some important points to think about:

Building Relationships: Trust is very important. Spend time building personal connections with your partners. This can lead to better teamwork and understanding.

Respect for Hierarchy: Chinese companies often have a hierarchy. Recognize and respect this structure in your talks and decisions.

Patience and Flexibility: Be ready for a different work pace. Patience and flexibility can help you handle challenges better.

Working together in joint ventures can use shared knowledge. Starting knowledge exchange programs lets you learn from the best practices around the world. Encouraging innovation through teamwork helps you meet market needs.

By following these best practices, you can build a strong base for successful teamwork with your Chinese partners in the automotive industry.

In conclusion, you should focus on having a clear timeline for your front suspension OEM/ODM projects. This timeline helps you handle each step well, from making samples to validation and PPAP submission. Working with Chinese partners can improve your project results. Their knowledge can make processes easier and lower costs. By paying attention to communication and understanding cultures, you can create strong relationships that lead to successful teamwork. In the end, these strategies will help you get great results in your front suspension projects.

FAQ

Why is sample development important in OEM/ODM projects?

Sample development helps make sure your front suspension parts meet design and performance needs. It lets you test and improve designs before making a lot of them. This lowers the chance of expensive mistakes.

How does Kingham keep its products high quality?

Kingham follows strict quality rules, like ISO 9001 and IATF 16949 certifications. They do careful testing and checks to make sure every part is safe and works well.

What problems might I face when working with Chinese manufacturers?

You might deal with language issues, cultural differences, and different quality standards. Good communication and understanding cultural details can help you handle these problems better.

How long does the PPAP process usually take?

The time for the PPAP process can change based on how complex the project is. Usually, it takes several weeks to months, depending on how many prototypes and tests are needed before getting final approval.

Can I change my suspension parts with Kingham?

Yes, Kingham has many options for customizing suspension parts. You can adjust designs, materials, and performance features to fit your specific needs and wants.