Achieving the best damping accuracy in 5-axis CNC machining depends on strong fixturing and careful batch consistency. These things are basic needs, not just good ideas. They help make sure parts have predictable, high-quality features. In tough situations, where controlling vibration is important, ignoring these factors can cause big problems.

Think about how stable processes matter. Strong fixturing and batch consistency create stability. This is key for reducing vibration in CNC work. A clear quality plan keeps size accuracy, which helps with vibration control. Consistent fixturing lets parts made at different times work the same, lowering differences in vibration.

Key Takeaways

Good fixturing is very important for keeping things steady and lowering vibrations during CNC machining.

Batch consistency makes sure that every production run has the same quality. This is very important for high-precision work.

Using standard setup steps and automated tool management can really help improve machining accuracy.

Advanced monitoring tools help find changes right away. This improves overall quality and cuts down on mistakes.

A complete process window that combines fixturing and batch control leads to better damping accuracy and product reliability.

Defining Damping Accuracy and Its Importance

What is Damping Accuracy?

Damping accuracy means how well a part, like a shock absorber, controls vibrations. For machined parts, it is very important for reducing vibrations and keeping the structure strong. High damping accuracy helps parts absorb shocks and use energy well. This is very important for high-precision uses, especially in car suspension systems. Even small mistakes can cause problems.

Why Damping Accuracy is Crucial

Damping accuracy is important for many reasons:

It affects how well the suspension system controls vehicle movement.

Good shock absorbers provide a smooth and safe ride by handling bumps.

Effective damping changes moving energy into heat, keeping tires on the road.

In high-precision uses, like Kingham‘s front-shock-absorber parts, damping accuracy greatly affects how well products work and last. For example, the right valve flow in the piston slows down energy, which reduces spring vibrations. Controlling wheel movement is key for comfort, safety, and performance.

Also, the materials, tool paths, and machine actions all help with damping accuracy. But, fixturing and batch consistency are often ignored. Manufacturers need to focus on these areas to get the best damping accuracy and make sure their products are reliable.

Optimizing Fixturing for 5-Axis CNC Damping Accuracy

Effective 5-Axis Fixturing Principles

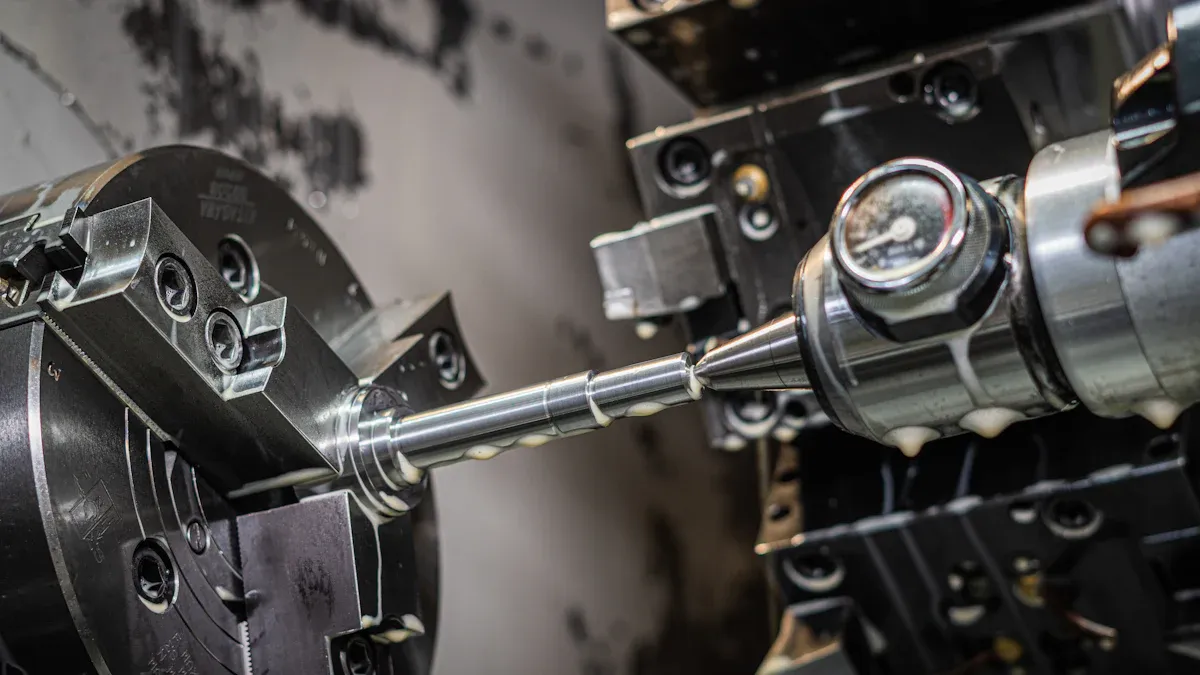

The way CNC fixtures are designed is very important for getting the best damping accuracy. Good fixturing affects how stiff parts are, how vibrations move, and how stable the machining is. Some key ideas are:

Uniform Clamping Pressure: Using the same clamping pressure while cutting stops part movement and improves stability. This helps keep everything aligned during machining.

Material Selection: Picking the right materials for fixtures is important for strength and to handle machining forces. Strong materials stop bending and vibrations, which helps with precise cutting.

System Rigidity: Making sure the whole system, like the machine table, fixture, and part, is very stiff helps it handle cutting forces and stops vibrations. This stiffness is key for keeping accuracy during machining.

Factor | Impact on Rigidity and Stability |

|---|---|

Material Selection | Affects strength and ability to handle machining forces. |

Rigidity | Stops bending and vibrations, ensuring precise cutting. |

Design Considerations | Accessibility, reducing interference, and compatibility improve performance. |

Common Fixturing Challenges and Solutions

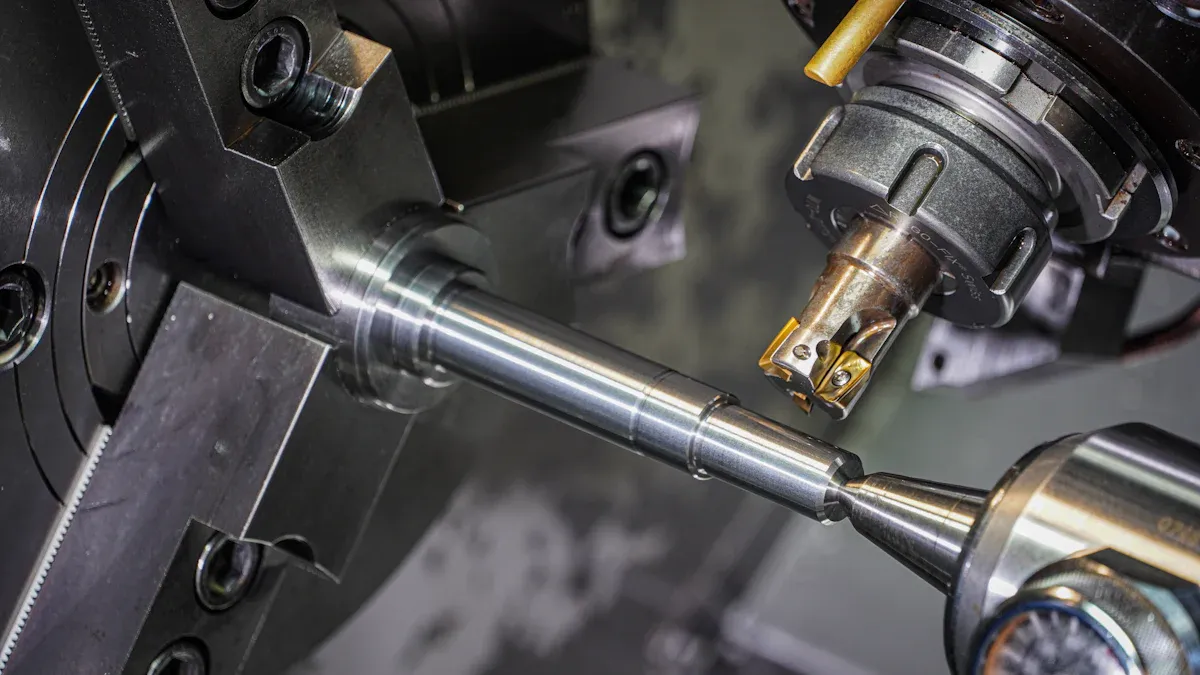

Holding a workpiece tightly during 5-axis machining can be tricky. The way parts rotate can cause instability, leading to movement that hurts quality and accuracy. Custom fixtures are often needed to ensure stiffness and precision.

Some common challenges are:

Challenge: Not enough support can cause part bending and chatter during machining.

To solve these problems, manufacturers can use several solutions:

Modular Fixturing: This method allows for flexible workholding, fitting different part shapes and sizes.

Vacuum Clamping: This technique spreads pressure evenly across the workpiece, lowering the chance of movement during machining.

Hydraulic Clamping: Hydraulic systems provide steady pressure, which is important for high-precision machining.

When choosing a clamping method, factors like workpiece material and production volume should be considered. For example, using strong hydraulic clamps for harder materials gives the needed force without causing damage. In high-volume production, pneumatic clamps can speed up setup times, improving output.

Example of Fixture Quality Impacting Damping Characteristics

Imagine a situation where a manufacturer uses a custom fixture made just for a complex part. By ensuring proper alignment and clamping, the fixture reduces vibration transfer during machining. This leads to a better surface finish and improved damping characteristics. The precise CNC machining at Kingham, with tolerances of 0.01mm, greatly depends on good fixturing to achieve these results.

Ensuring Batch Consistency in 5-Axis CNC Machining

Sources of Batch Inconsistency

Batch inconsistency in 5-axis CNC machining can happen for many reasons. Some main causes are:

Material Inconsistencies: Differences in raw materials can change sizes.

Tool Wear: Worn-out cutting tools can lose precision, causing batch inconsistency.

Machine Variability: Things like heat changes and spindle runout can create errors in machining.

Environmental Factors: Conditions like temperature and humidity can slightly change machining results.

Operator Practices: Different setups or adjustments by operators can cause changes in the final product.

Strategies for Maintaining Batch Consistency

To keep batch consistency, manufacturers can use several methods:

Standardized Setup Procedures: Having the same procedures for machine setup reduces differences.

Automated Tool Management: Using machines for tool changes ensures steady performance.

In-Process Monitoring: Tools like force sensors and acoustic monitoring give real-time feedback on machining. These systems help find changes that could affect quality.

Tip: Statistical process control (SPC) is very important for keeping quality during production. By measuring key sizes and using control charts, operators can track changes over time.

Process Windows for Batch Consistency

Setting and following strict process windows is key for keeping consistent damping properties in batches. Important factors include:

Spindle Speed: Keeping spindle speeds the same ensures even cutting conditions.

Feed Rate: A steady feed rate helps control cutting forces.

Depth of Cut: Keeping the same depth of cut stops changes in material removal.

Coolant Flow: Good coolant flow lowers heat effects and keeps tools working well.

In precision industries, even a ±0.01mm difference can greatly affect assembly. So, setting these process windows is crucial for meeting important tolerances in robotic assemblies and ensuring overall performance.

Integrating Fixturing and Batch Control for Robust Process Windows

Synergy of Fixturing and Batch Control

To get the best damping accuracy in CNC machining, fixturing and batch control must work well together. You need both parts to succeed. A strong fixture helps with steady machining. At the same time, consistent processes stop fixture problems from getting worse. How these two parts work together is very important for keeping the process stable.

Manufacturers should pay attention to some key points to ensure stability:

Careful Parameter Selection: Picking the right fixturing settings is very important. For example, using mechanical locators and edge clamps can help stop parts from moving during machining.

Rigid Workholding: A strong workholding system keeps parts still, which is key for accuracy.

Proper Tool Maintenance: Regularly checking and changing tools helps keep performance steady.

Real-Time Compensation: Using systems that adjust for changes during machining improves stability.

By focusing on these points, manufacturers can create a more dependable machining environment. This leads to better quality and accuracy.

Developing a Comprehensive 5-Axis Process Window

Creating a complete 5-axis process window involves several important steps. Each step helps ensure damping accuracy and overall machining performance. The table below shows these steps:

Step | Description |

|---|---|

1 | Check the acceleration/jerk curve through simulation to find instability points. |

2 | Improve the tool axis vector to lower dynamic errors and make surfaces smoother. |

3 | Use a layered machining plan (roughing, semi-finishing, finishing) with a uniform finishing allowance of 0.5–1.0 mm. |

4 | Use strong toolholders and the right cutting settings to keep stability. |

5 | Check and fix RTCP to make sure spatial accuracy is correct. |

6 | Fix thermal errors with data-driven online compensation models. |

7 | Improve geometric tolerances using sensitivity analysis and multi-objective optimization. |

8 | Set up real-time detection and closed-loop compensation systems. |

9 | Make a practical plan that covers toolpath optimization, RTCP checking, thermal error modeling, and regular QA cycles. |

By following these steps, manufacturers can create a process window that includes both fixturing settings and batch control methods. This complete approach makes sure that damping accuracy stays the same across different production runs.

Advanced Tools for Enhanced Control

Advanced metrology and simulation software are very important for creating and keeping strong process windows in CNC machining. These tools let manufacturers watch and change processes in real-time, improving overall quality and accuracy. The table below shows key features of these advanced tools:

Feature | Description |

|---|---|

Automated Tool and Work Offset Correction | Continuously checks machining conditions and changes tool paths to adjust for tool wear and thermal changes. |

Statistical Process Control (SPC) | Offers real-time monitoring and detailed reports to track trends and keep quality control. |

Provides support for operators, reducing training time and improving interaction with the software. | |

Gives context-aware help to operators, assisting them with settings and tool configurations. |

Also, adaptive control systems improve process window stability by constantly checking cutting loads. These systems automatically change the cutting feed rate based on real-time information. This ability is very important for keeping stability, especially when unexpected changes happen during machining, like differences in material hardness or tool wear. By using these advanced tools, manufacturers can achieve higher precision and better surface finish in their machining processes.

Getting accurate and steady damping in 5-axis CNC machining comes from well-made fixtures and careful batch consistency. A clear process window that combines these parts is very important for making high-quality parts reliably.

Manufacturers who understand these combined process controls enjoy many long-term benefits, such as:

Benefit | Description |

|---|---|

Keeps machining accuracy the same over time, which is key for high-precision industries. | |

Reduced Dimensional Deviations | Cuts down on errors in part sizes, leading to better fitting and working parts. |

Enhanced Quality Consistency | Makes sure quality is the same across production runs, lowering differences in output. |

Extended Tool Life | Damping technology helps tools last longer, which means lower replacement costs and less downtime. |

Improved Surface Finish | Better surface finishes improve overall product quality and cut down on extra work needed. |

Reduced Operational Costs | Overall gains in efficiency and productivity lead to lower manufacturing costs. |

By focusing on these points, Kingham works towards its goal of providing professional component solutions that improve the riding experience.

FAQ

What is the role of fixturing in CNC machining?

Fixturing gives support and stability during CNC machining. It keeps parts in place, which reduces vibrations and helps with precision. Good fixturing affects the quality of the final product.

How does batch consistency affect damping accuracy?

Batch consistency makes sure each production run has the same quality and performance. Changes in materials or processes can cause differences in damping accuracy, which affects how well components work.

What are common challenges in maintaining batch consistency?

Common challenges include differences in materials, tool wear, and environmental factors. These issues can cause variations in machining. It is important to use standard procedures and monitoring systems.

How can manufacturers optimize their CNC processes?

Manufacturers can improve CNC processes by setting strict process windows, using advanced monitoring tools, and ensuring proper fixturing. These steps help keep quality consistent and improve damping accuracy in batches.

Why is damping accuracy important in robotics component development?

Damping accuracy is very important in robotics component development. It affects how stable and well robotic systems work. High damping accuracy ensures smooth operation and helps parts last longer.