Upgrading the brakes on your scooter or small motorbike can greatly improve safety and performance, especially with our Brake Upgrade Line. The global scooter market was worth USD 70.26 billion in 2022 and is expected to grow by 6.1% each year from 2023 to 2030. This growth indicates that more people are seeking better braking solutions. As cities expand, more riders are looking for efficient ways to navigate their surroundings.

Customers are demanding high-quality brake parts that meet safety standards, and they also desire enhanced performance, which increases the need for innovative brake upgrade options like our Brake Upgrade Line. These factors make brake upgrades essential for today’s riders, ensuring they can stop safely when it matters most.

Key Takeaways

Upgrading brakes makes scooters and small motorbikes safer and better. It meets the need for improved braking options.

Design brake kits to fit different models. Choose between specific kits and shared kits for better fit and flexibility.

Divide the market by how users ride and the conditions. This helps create products that fit different customer needs well.

Use a clear pricing plan with different product levels. Offer basic, mid-range, and premium kits to attract various customers.

Keep control of profits by improving your supply chain. Use market prices to stay profitable and competitive.

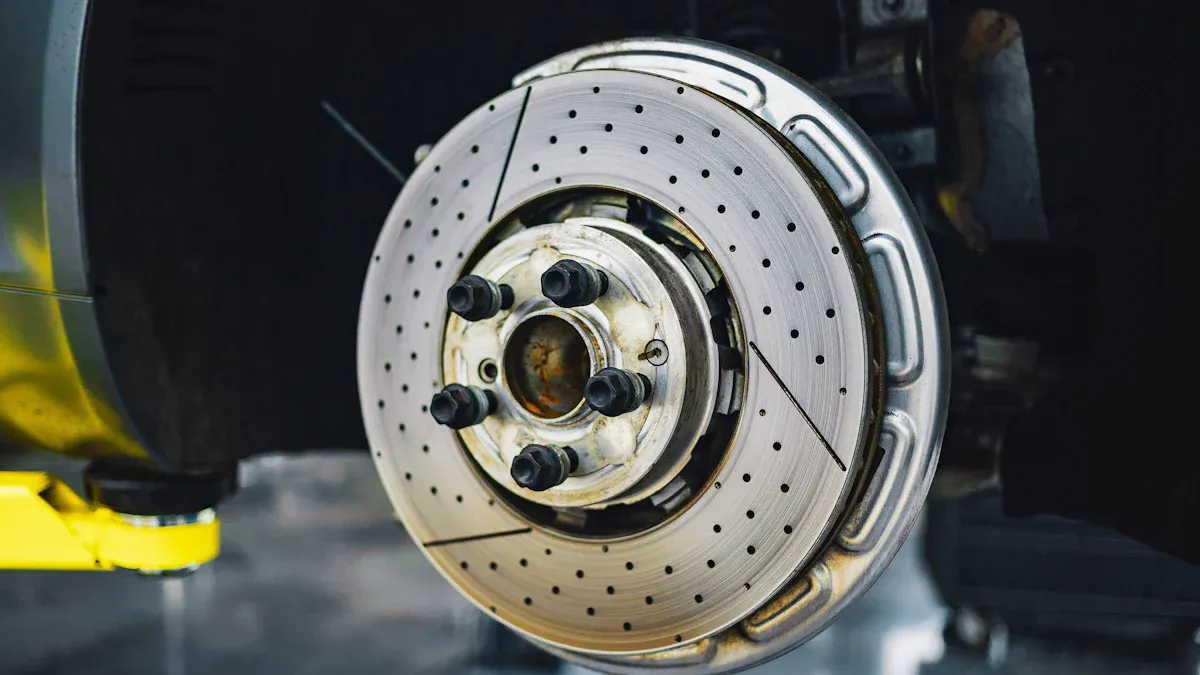

Brake Kit Design for Scooter and Small Motorbike Platforms

Platform-Based Kit Architecture

When you design brake kits for scooters and small motorbikes, you can pick between two types: model-specific and platform-shared kits.

Model-specific kits are made for each scooter or motorbike model. They fit perfectly and work best.

Platform-shared kits can be used on many models. This gives you flexibility and saves money. You can keep fewer parts in stock while still helping different customers.

Compatibility is very important in brake kit design. You need to think about the caliper, disc, and hose compatibility. Each part must work well together for good braking performance. For example, if you use a caliper for a certain model, it must match the disc size and hose fittings to work right.

Performance and Compliance Standards

Setting performance standards is key for brake kits. You should aim for certain braking force targets, especially for city and commuter use. Riders need dependable stopping power in all conditions.

Here are some important performance tests that brake kits must pass:

Performance Test | Description |

|---|---|

Stopping Distance | The brake system must stop the motorcycle from 30 mph and 60 mph within set distances. |

Fade Resistance | The system must keep working well under repeated use without losing effectiveness. |

Water Recovery Test | Compares braking performance before and after being in water, ensuring little performance loss. |

Partial Failure Test | The system must still work well even if a pressure part fails. |

Durability Inspection | The brake system must pass a durability check after all tests are done. |

Also, you must make sure your brake kits meet regulatory standards. Different areas have their own rules. For example:

Region | Regulatory Body | Key Standards | Description |

|---|---|---|---|

US | NHTSA | FMVSS 121 | Sets performance rules for air brake systems, including testing for reliability and safety. |

EU | UNECE | ECE R13 | States performance rules for braking systems on heavy commercial vehicles, focusing on agreement among member countries. |

China | National Standards | GB 5767-2008 | Sets performance rules for pneumatic braking systems, with less strict enforcement than US and EU rules. |

Installation and Service Considerations

Easy installation is very important for dealer workshops. You want your brake kits to be installed quickly and easily. This lowers labor costs and makes customers happy.

Compatibility with stock master cylinders and wheels is also very important. If your brake parts do not fit well with existing systems, it can cause performance problems. So, designing kits that work with popular stock parts can make installation easier and improve overall performance.

Assortment Strategy: Building a Sellable Brake Line

Segmenting the Market by Use Case

To build your brake upgrade line well, divide the market by how users ride and where they ride. Knowing these things helps you create products that fit their needs. Here’s how different factors affect your design:

Influence Factor | Description |

|---|---|

User Behavior | More motorcycle sales and city growth create a need for better brakes. |

Safety Features | More people care about safety, so companies add better braking technology. |

Regulatory Compliance | Tougher safety rules require new braking solutions that follow safety standards. |

Performance and Customization | Riders want brakes they can customize, especially sportbike fans, which affects design. |

Assortment Layering and SKU Structure

When you create your product line, think about layering your items for different prices and customer needs. Top brands often look at their competition and pricing plans. They use market research to check how products do at stores. This helps them understand pricing and promotions. Here are some good strategies:

Offer a basic line for riders on a budget.

Provide mid-range options for regular users.

Create high-end products for performance lovers.

This layered method helps you reach different market groups while maximizing your sales.

Managing Complexity Without Overloading Dealers

As you create your brake upgrade line, keep things simple. Giving dealers too many products can confuse them and cause problems. Focus on a clear product line that balances variety and simplicity. Here are some tips:

Limit how many versions of each product you have.

Make sure to explain product features and benefits clearly.

Offer training and support to help dealers understand what you offer.

By keeping things simple, you help dealers sell your products better, boosting their confidence and your brand’s image.

Margin Control Across the Brake Upgrade Line

Pricing Architecture and Product Laddering

To make more money, you need a good pricing plan. Start by making a product ladder. This lets you offer different prices for different types of customers. You can include:

Basic Kits: Cheap options for riders on a budget.

Mid-Range Kits: Good choices for regular users wanting better performance.

Premium Kits: Top-quality products for fans who want the best.

This setup helps you reach more customers while keeping good profits.

Cost Structure and Supply Chain Levers

Improving your cost structure is key to boosting profits. You can do this by making your supply chain work better. Use strategies like:

Lowering variable costs.

Increasing production amounts.

Standardizing parts across models.

For instance, cutting shipping costs from 55% to 35% can raise your operating profits by 2 percentage points. Also, making 7,000 units instead of 800 lowers the fixed cost for each unit. This method protects your profit margins and increases earnings.

Margin Protection at Dealer Level

Keeping margins safe at the dealer level is important for lasting success. Think about these smart strategies:

Market-Based Pricing: Set prices based on what competitors charge to stay competitive without starting price wars.

Value-Based Pricing: Focus on how much customers think your products are worth. Show benefits and unique features to explain higher prices.

Parts Pricing Matrix: Use a clear pricing method that applies different markups based on part costs. This keeps profits steady across your different products.

High-quality, limited-fit kits can allow for higher dealer markups. Customers often pay more for better performance and brand trust, so it’s important to highlight these points in your marketing.

In conclusion, making a good brake upgrade line needs careful planning. You should think about kit design, making sure parts fit and work well. A smart product mix helps you meet different customer needs while keeping things simple. Good margin control protects your profits and keeps your business running.

As you start your own brake upgrade projects, keep these important points in mind:

Vehicle safety rules affect your designs.

More people want high-quality products.

City growth increases the need for better brakes.

By using these ideas, you can build a brake upgrade line that stands out in the market.

Check out your options and improve your designs to boost rider safety and performance! 🚀

FAQ

What are the benefits of upgrading my scooter’s brakes?

Upgrading your scooter’s brakes makes stopping easier. It also improves safety and boosts overall performance. You will have better control, especially in busy areas. This makes your rides safer and more fun.

How do I know which brake kit to choose?

Pick a brake kit that fits your scooter model and riding style. Think about things like how well it performs, your budget, and if it works with your current parts. Looking into options helps you make a smart choice.

Can I install the brake upgrade kit myself?

Yes, many brake upgrade kits are made for easy setup. But if you are not sure, ask a professional mechanic for help. Proper installation is important for good performance and safety.

Are there any maintenance tips for upgraded brakes?

Check your brake pads often for wear and change them when needed. Keep the brake fluid levels full and look for leaks in the hoses. Regular maintenance helps your upgraded brakes work well.

How do I ensure my brake upgrade meets safety standards?

Make sure your brake upgrade kit follows local rules and safety standards. Look for certifications from trusted organizations. This guarantees your upgrade gives the safety and performance you need.