Aprilia Scooter Suspension Programs

Manufacturer & OEM/Wholesale Supplier

- IATF 16949 & ISO 9001 certified processes ensure reliable, premium quality

- In-house CNC machining + anodizing control for consistency

- Built for “Crossover Control (SR GT)” and “Premium GT Stability (SR MAX)” programs

- OEM/ODM support for new platform development

Built for Aprilia Distributors, Brands and Workshops

Distributors & Importers

Starter assortments that look premium in dealer channels.

Fitment confirmation by model year via email.

Aftermarket & OEM Brands

Tuning Shops & Service Centers

Aprilia Platform Overview

SR GT and SR MAX serve different premium roles: SR GT is an urban crossover that needs confidence on broken roads; SR MAX is a maxi-scooter where buyers pay for GT stability and refined feel. Plan your catalog by role and tier—then expand by model-year.

Platform

Typical Role

Key Markets

Main Suspension Opportunities

SR GT

Urban crossover (city + rough roads)

EU / SEA urban markets

Better compliance on broken roads, confidence on mixed surfaces, controlled chassis pitch under braking

SR MAX

Premium GT maxi-scooter

EU / premium channels

High-speed stability, heat/fade control on long rides, premium feel & appearance

Product Segmentation for Aprilia Partners

We’ve segmented Aprilia suspension solutions into three key tiers: "Essential (Good)", "Performance (Better)", and "Premium (Best)". Distributors can optimize their margin and inventory with our tiered structure.

Essential OE-Plus(Good)

Entry-level upgrade focusing on daily urban reliability and smooth commuting. A high-durability replacement for the Aprilia SR series.

- Who it’s for: distributors entering Aprilia scooter category + workshops needing fast-install upgrades

- Stock first: 3–4 core movers (common lengths + finishes), confirm model-year by email

- How it makes money: fastest turnover + lowest claim risk → easiest replenishment tier

Performance Adjustable(Better)

Mid-tier sport solution designed for sharper braking recovery and agile handling. The core program for SR GT and SR MAX performance upgrades.

- Who it’s for: premium dealers + workshops selling a clear “control / braking recovery” story

- Stock first: SR GT control movers + SR MAX refinement movers (4–6 SKUs)

- How it makes money: margin pickup tier → upsell from Essential with simple narrative

Premium / GT Line(Best)

Flagship GT architecture offering maximum touring confidence and high-end stability. Precision components for premium Aprilia brand positioning.

- Who it’s for: premium channels and private-label programs

- Stock first: flagship GT SKUs + finish variants (add after 60–90 days sell-through)

- How it makes money: higher ASP + premium positioning SKUs that anchor the catalog

Core Suspension Picks for Aprilia Programs

Suspension Upgrades for Aprilia SR GT — Crossover Control Program

SR GT buyers expect city agility plus confidence on broken roads. A winning SR GT program sells on compliance, controlled chassis pitch, and a clear upgrade ladder for premium distributors and workshops.

The Limits of Stock Suspension

- Off-Asphalt Control: Stock damping struggles with rapid, small irregularities on rough or unpaved surfaces, causing tire chatter and loss of stability.

- Limited Travel Utility: Insufficient suspension travel management compromises ground clearance and stability when encountering obstacles, hindering its adventure capability.

Kingham Tech Engineering Advantage

- Increased Travel & Clearance: Upgraded component lengths provide essential increased ground clearance for obstacle management while maintaining optimal handling geometry.

- Dual-Rate Spring System: Utilizing a spring system optimized for comfort on small inputs and firm support on large impacts, ensuring versatile performance across all terrains.

H117 GOLD

H117 BLACK

H012 YELLOW

H012 BLACK

H012 SILVER

Q053

Performance Solutions for Aprilia SR MAX — Premium GT Stability Program

Performance Deficiencies of Stock Unit

Chassis Pitch Control: Inadequate damping control, especially under hard braking, leads to excessive chassis pitch (dive and squat), compromising rapid cornering stability.

High-Speed Thermal Fade: Continuous operation at high speeds and high load can cause standard shock oil to overheat, leading to damping fade and loss of stability over long distances.

Kingham Tech Engineering Advantage

High/Low Speed Damping Adjustment: Integrating separate adjustments for high and low shaft velocities, allowing precise tuning for both fine road chatter and aggressive cornering forces.

Sealed Monotube Design: Utilizing robust monotube construction for superior heat dissipation and structural integrity, ensuring performance consistency on demanding touring routes.

H117 GOLD

H117 BLACK

H012 YELLOW

H012 BLACK

H012 SILVER

Q035

Aprilia Starter Program

- Coverage: SR GT + SR MAX

- SKU Count: 6–9 core movers(Good/Better/Best)

- Business Focus: Premium-looking assortment without overloading inventory

Your Expert Partner in Suspension Manufacturing

Design & R&D

Our experienced R&D team, with over 15 years of industry expertise, develops more than 20 new products annually for our clients. Leveraging over 70 technical patents, we collaborate with customers to ensure their brands maintain sustained competitiveness in the market.

Advanced Manufacturing

Our modern manufacturing facility spans over 16,000 square meters, equipped with more than 90 CNC precision machines and a dedicated anodizing workshop. We utilize automated assembly and testing equipment while implementing comprehensive quality inspections to ensure every product meets the highest standards.

Global Partnership

With over 7 years of ODM/OEM service experience, we have successfully served aftermarket clients across Europe, the United States, and Southeast Asia. We provide comprehensive customization services, committed to becoming your most trusted suspension system solutions provider.

Performance Validation & Reliability Metrics

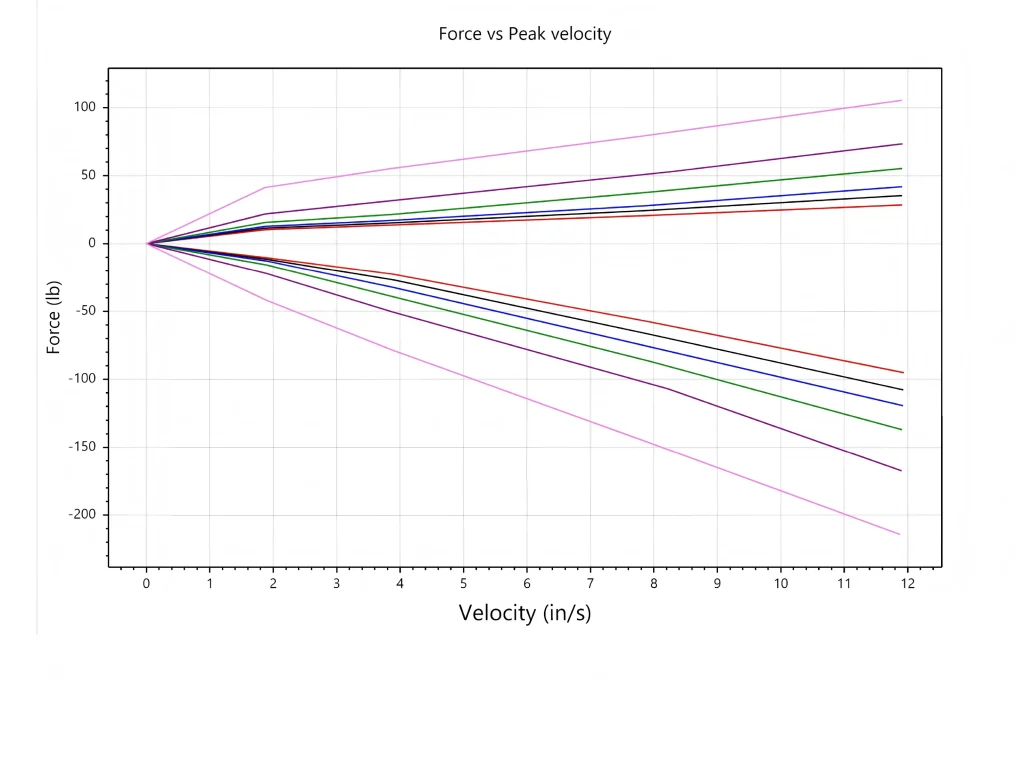

Quantified Damping Performance

This Force vs Velocity curve is the definitive proof of our performance. It confirms that our damping system maintains predictable force output and consistency, ensuring balanced and superior handling across all operating speeds.

Structural Reliability

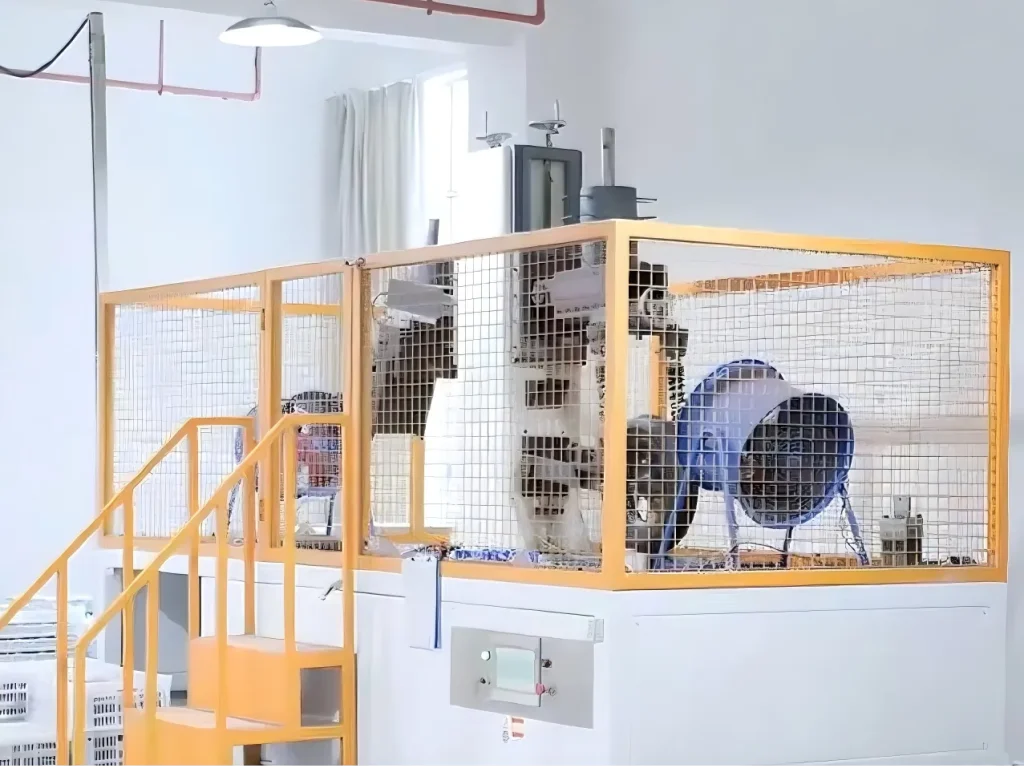

Testing

Critical components undergo rigorous fatigue testing on specialized equipment. This protocol validates the structural integrity of our components, providing partners with confidence in the long-term durability and warranty commitment.

Production Quality & Consistency

Every unit undergoes high-speed dyno validation to verify precision before packaging. This quality control step guarantees that all production batches meet the same high standard of control and stability.

Component & Environmental Verification

We confirm material integrity and component precision using dedicated inspection equipment. All external alloys are tested for superior corrosion resistance, confirming their durability in diverse global environments.