Choosing the right motorcycle shock absorber suppliers is very important for your success in the OEM market. Suppliers that invest in research and development can greatly improve product quality and performance. New materials and smart technologies, like AI for real-time adjustments, lead to better ride comfort and safety. Additionally, as customers seek lighter and eco-friendly options, it is essential to localize suspension tuning to meet these needs. A strong partnership with the right suppliers not only enhances your products but also helps you stay ahead in the evolving market.

Key Takeaways

Pick suppliers who care about product performance and quality. Find those with strict quality checks to keep rides safe and comfortable.

Choose suppliers that use new technology. Features like electronic suspension systems and light materials improve performance and meet what customers want.

Run pilot projects to test supplier products in real-life situations. Pay attention to key performance indicators to see how well shock absorbers work in different conditions.

Adjust suspension tuning to fit local market needs. Knowing local likes and rules helps make products that customers want.

Create strong, long-lasting relationships with suppliers based on trust and communication. Working together on improvements leads to better product quality and new ideas.

Supplier Evaluation Criteria

When you look at motorcycle shock absorber suppliers, you need to think about some important criteria. These criteria will help you find suppliers who can meet your needs for performance and quality.

Product Performance and Quality

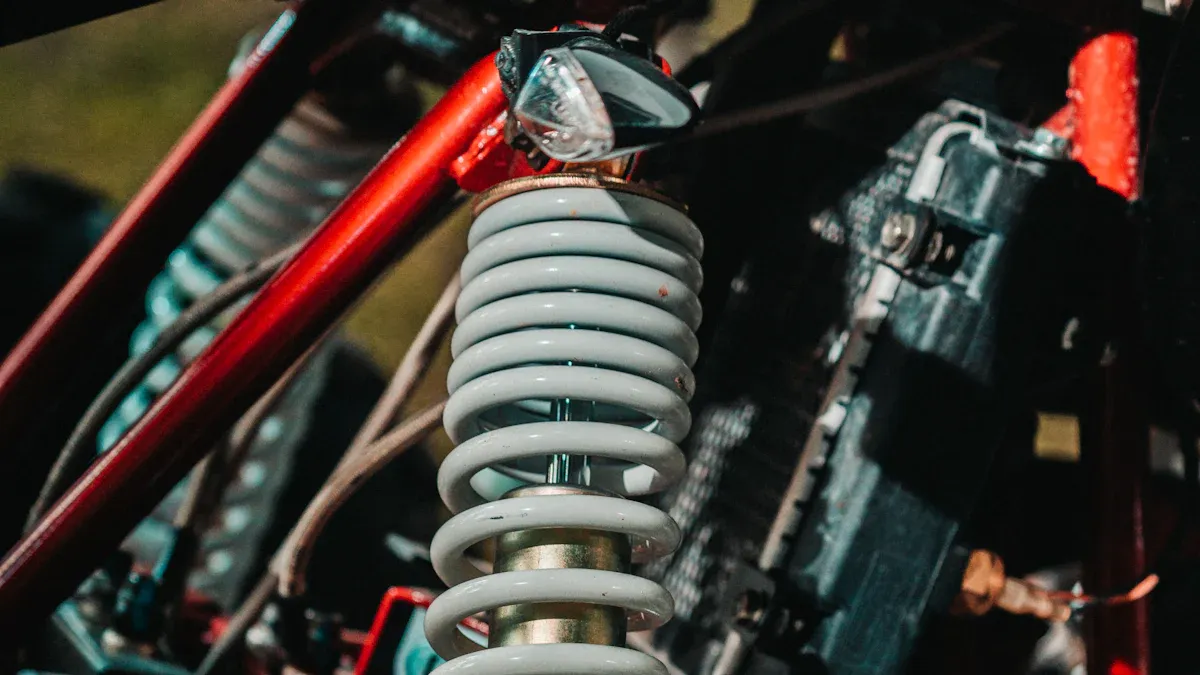

Product performance is very important in the motorcycle world. You want shock absorbers that make riding better, keeping you safe and comfortable. Top suppliers use strict quality control and testing. They make sure every product meets high industry standards. For example, Cogent Dynamics has a careful 5-step quality check. This check includes final inspection and performance records before shipping any product. This careful work ensures all parts meet tough quality rules.

Also, suppliers test their products a lot. This testing makes sure each shock absorber works well in different situations. RFY SHOCK focuses on ongoing technology improvements and great craftsmanship in making their products. These methods are key for creating high-quality motorcycle shock absorbers that improve rider safety and performance.

Technological Innovation in Suspension

New technology is very important for motorcycle suspension systems. You should find suppliers who spend money on research and development to stay ahead in this tough market. Recent new ideas include:

Electronic Suspension Systems: These systems change damping based on road conditions.

Adaptive Suspension: Changes preload automatically based on rider weight and terrain.

Lightweight Materials: Using carbon fiber and titanium cuts weight while boosting performance.

These new features not only make motorcycles perform better but also meet the rising demand for high-performance bikes. Suppliers are also working on advanced safety features like anti-lock braking systems (ABS) to meet strict rules.

Manufacturing Capabilities and Reliability

Manufacturing abilities are another key part of checking suppliers. You want to work with suppliers who show they can be reliable and grow in their production. Look for proof of their quality commitment, like certifications such as ISO 9001 and ISO TS/16949. These certifications show a supplier follows high-quality management rules.

Certification Type | Importance | Description |

|---|---|---|

ISO 9001 | High | General quality management standard |

ISO TS/16949 | High | Quality management for automotive production |

Also, check their sourcing methods. A clear product information system and great customer service make sourcing and ordering easier. Good after-sales support is also very important. It builds trust and helps create long-term partnerships.

Importance of Pilot Projects

Pilot projects are very important for checking motorcycle shock absorber suppliers. These projects let you test products in real-life situations. This way, you can see if they meet your performance needs. By doing pilot projects, you can collect useful information on how well a supplier’s products work in different conditions.

Testing Supplier Products

During pilot projects, focus on key performance indicators (KPIs) to check how well the shock absorbers work. Think about these KPIs:

KPI | Description |

|---|---|

Manufacturing Expertise | Experience in making specific shock absorbers, backed by technical documents. |

Quality Management Systems | Certifications like ISO 9001 and IATF 16949 show strong quality control and process discipline. |

Production Capacity | Ability to handle current and future orders, showing flexibility and growth. |

Supply Chain Reliability | Information on timely delivery and good communication, which is key for smooth operations. |

You can use advanced testing machines with sensors to gather data on different performance measures like force, displacement, temperature, and speed. This data helps you check how well the shock absorbers dampen and if they meet the required standards.

Assessing Compatibility with OEM Standards

It is very important that shock absorbers fit OEM standards. This ensures they work well in your motorcycle designs. Be aware of possible problems, such as:

Bad handling and instability if the shock doesn’t fit the suspension.

Damage to parts like rods and bushings, which can cause cracks or misalignment.

Overloading shocks by not considering rider, passenger, or luggage weight, which can lead to sagging or broken parts.

By fixing these compatibility issues during pilot projects, you can avoid expensive mistakes. This ensures the products you choose improve your motorcycles’ overall performance.

Localizing Suspension Tuning

Understanding Market Needs

To do well in the motorcycle business, you need to change your suspension systems to fit local market needs. Each area has different requirements that affect how you design and adjust your products. For example, North America focuses on fun riding, while Europe has strict safety rules. In the Asia-Pacific area, more people are buying motorcycles for everyday travel because they have more money. At the same time, cities in the Middle East and Africa want motorcycles for fun.

Knowing these market trends helps you adjust your suspension systems better. You can learn more through different ways, like:

Methodology | Description |

|---|---|

Experimental Analysis | Check how comfortable passengers are with different rear springs on motorcycles. |

Data Collection | Use triaxial accelerometers to track vibrations during real-world tests. |

Market Surveys | Ask people what they like and expect from motorcycles. |

By using these methods, you can make sure your products fit local needs and wants.

Adapting Products for Regional Preferences

After you know what the market needs, you can change your suspension systems to match. OEMs look at several things when adjusting suspension tuning:

Market Conditions: Look at local market conditions to guide your tuning plans.

Consumer Preferences: Knowing what consumers want is key for adjusting suspension systems.

Regulatory Environments: Following local rules affects how you design and tune suspensions.

For instance, Showa’s dual bending valve front fork technology is a smart choice for suspension tuning. This technology is lighter and gives good performance like more expensive options, which is great for OEMs focused on market needs.

Also, cultural and environmental factors are important for suspension needs. In Japan, the motorcycle culture wants high-quality suspension systems. In the United States, many people like to customize their bikes, leading to a need for different suspension options.

Kingham is great at customizing suspension solutions for special market needs. The company does detailed market research to understand global rules and trends. They work with brands to set performance and style goals, making sure the suspension systems are comfortable and safe. Kingham’s focus on advanced research and development helps them keep improving suspension technology.

Aspect | Description |

|---|---|

Market Analysis | Kingham does detailed market research to understand global rules and trends. |

Collaboration | They partner with brands to set performance and style goals. |

Advanced R&D | Focus on advanced research and development to improve suspension technology. |

Precision Manufacturing | Uses precise manufacturing methods to ensure quality and fit. |

Compliance with Standards | Makes sure products meet global safety rules and fit vehicle needs. |

By localizing suspension tuning, you make your products more valuable and ensure they connect with your target audience. This not only makes riders happier but also strengthens your brand in the competitive motorcycle market.

Building Long-Term Supplier Relationships

Establishing Trust and Communication

Trust is very important when working with your suppliers. It helps create a good partnership. You can build trust by talking openly and working together. Guillermo Cano told a great story about changing a unsure customer into a loyal fan. His team started working together early, even during tough times like COVID. They made parts on time and met quality and cost goals. This success happened because they had an open way of solving problems together.

To build trust, think about these ideas:

Strong support and collaboration with suppliers makes customers happier.

Effective communication and solving problems help the partnership succeed.

Transparency in how things work builds long-term loyalty.

Continuous Improvement and Innovation

Always improving is key to keeping high-quality products. Good relationships with suppliers help ensure timely deliveries and high standards. Working together leads to new ideas that help both sides. Here are some ways suppliers improve quality and innovation:

Using advanced technologies like IoT and AI for real-time checks.

Using Just-In-Time (JIT) and lean inventory to reduce waste.

Keeping strict quality control standards with careful testing.

Also, OEMs and suppliers often work together on research and development for better suspension systems. For example, a U.S. EV startup is teaming up with a Japanese company to create special dampers. These partnerships speed up the use of new technologies and improve product performance.

By focusing on trust, communication, and continuous improvement, you can create strong, lasting relationships with your suppliers. This not only improves your product quality but also helps you succeed in the competitive motorcycle market.

Checking motorcycle shock absorber suppliers carefully gives you important long-term benefits. You can look forward to:

Better product quality from trustworthy supplier partnerships.

Improved safety and performance by following industry rules.

Easier communication and quick responses from suppliers, making operations smoother.

Less risk in the supply chain, which helps avoid problems.

Also, adjusting suspension tuning to local needs is very important for your success in the market. Think about these key points:

Key Points | Description |

|---|---|

Changing products to fit local needs boosts performance and safety. | |

Regulatory Compliance | Local tuning helps OEMs follow local laws. |

Market Strategies | Focusing on new ideas and efficiency increases customer interest. |

By focusing on these strategies, you can make your OEM partnerships stronger and keep customers happy.

FAQ

What are the key benefits of using high-quality motorcycle shock absorbers?

High-quality motorcycle shock absorbers make rides more comfortable. They also help with handling and safety. These shock absorbers give better stability and control, especially on tough roads. This means a smoother ride for you.

How can I determine if a supplier meets OEM standards?

You can check if a supplier meets OEM standards by looking at their certifications. Review their quality management systems and past performance records. Doing pilot projects can also help you see if their products fit your needs.

Why is localizing suspension tuning important?

Localizing suspension tuning is very important. It helps you meet the needs of different markets. Each area has its own riding conditions and preferences. These factors affect how suspension systems should work for safety and comfort.

What should I look for in a supplier’s manufacturing capabilities?

When checking a supplier’s manufacturing abilities, think about their production capacity. Look at their quality control processes and the technology they use. Certifications like ISO 9001 show they are serious about keeping high standards in manufacturing.

How can I ensure a long-term partnership with my suppliers?

To build a long-term partnership with suppliers, focus on open communication and trust. Work together and talk about improvements and new ideas. Giving feedback regularly can help make the relationship stronger.