OEM procurement means getting parts to make vehicles, like brake systems. These parts are very important for safety. It is crucial that these parts meet quality standards. For example, ISO 26262 is about safety in vehicles. It helps make sure brakes do not have risks. Failure Mode and Effect Analysis finds possible failures. This makes safety better during design. This table shows how they are used:

Standard | Overview | Application |

|---|---|---|

ISO 26262 | Focuses on safety for electrical and electronic systems in vehicles. | Makes sure that safety systems (like brakes) are designed to avoid risks and meet safety needs. |

Failure Mode and Effect Analysis (FMEA) | Finds possible failures in products or processes. | Used during design for safety parts like brakes, helping to make safer products. |

Following quality standards helps create reliable supply chains and safer vehicles.

Key Takeaways

Quality standards like ISO 26262 and FMEA are very important. They help keep brake parts safe and reliable in cars.

OEM procurement makes sure parts are high-quality. These parts follow strict safety and performance rules. This lowers the chance of brake problems.

Kingham Technology shows its commitment to quality. They follow international standards and use modern manufacturing methods.

Choosing trustworthy suppliers is key. It is also important to follow industry standards. This helps keep a strong supply chain in OEM procurement.

Ongoing improvement methods, like teamwork and quality checks, make products more reliable. They also help keep customers happy.

Understanding OEM Procurement

Definition and Importance

OEM procurement means getting parts straight from the original makers. This way, manufacturers get high-quality parts that follow strict safety and performance rules. OEM parts usually go through tough testing and meet specific making standards. This is different from aftermarket parts, which can have different quality and performance. The table below shows the main differences between OEM and aftermarket parts:

Aspect | OEM Components | Aftermarket Components |

|---|---|---|

Manufacturing Standards | Strong alloys, advanced materials, strict testing | Different making methods, quality issues |

Performance Testing | Specific stress tests, ISO 9001 rules | May not have complete performance checks |

Warranty Coverage | Long coverage periods | Varies a lot, some have little protection |

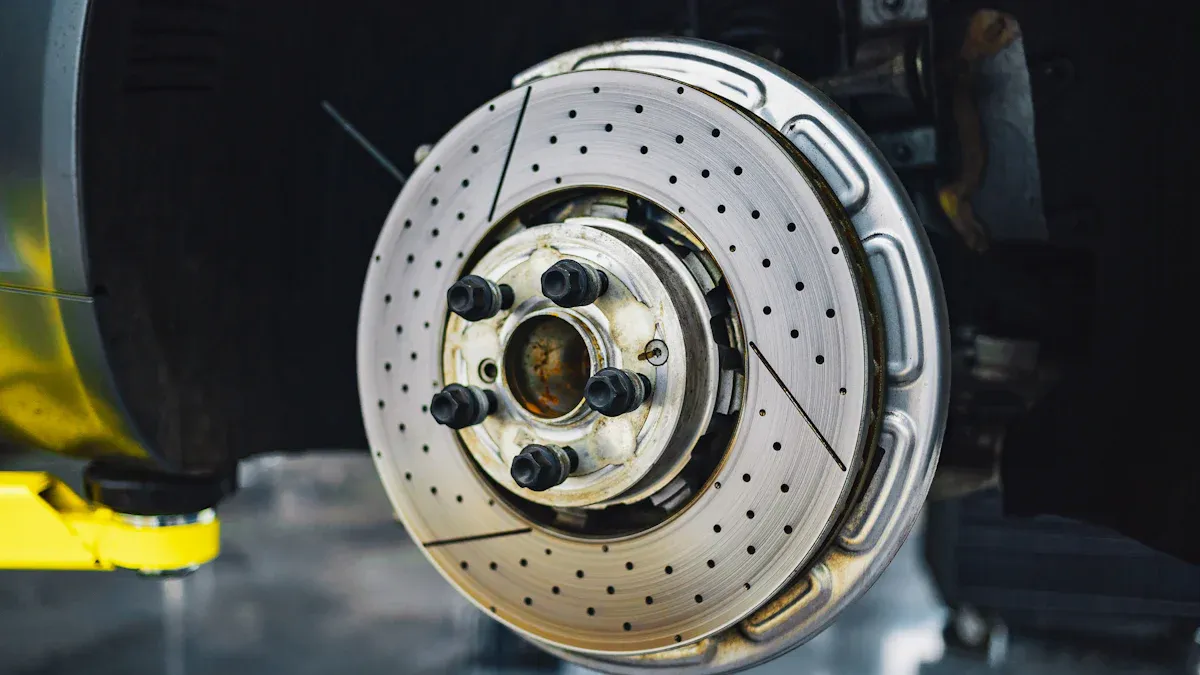

OEM procurement is important because it helps make vehicles safer and more reliable. By using parts that meet quality rules, manufacturers can lower the chances of brake failures. This is very important in the car industry, where safety matters most.

Kingham’s Role in Brake Components

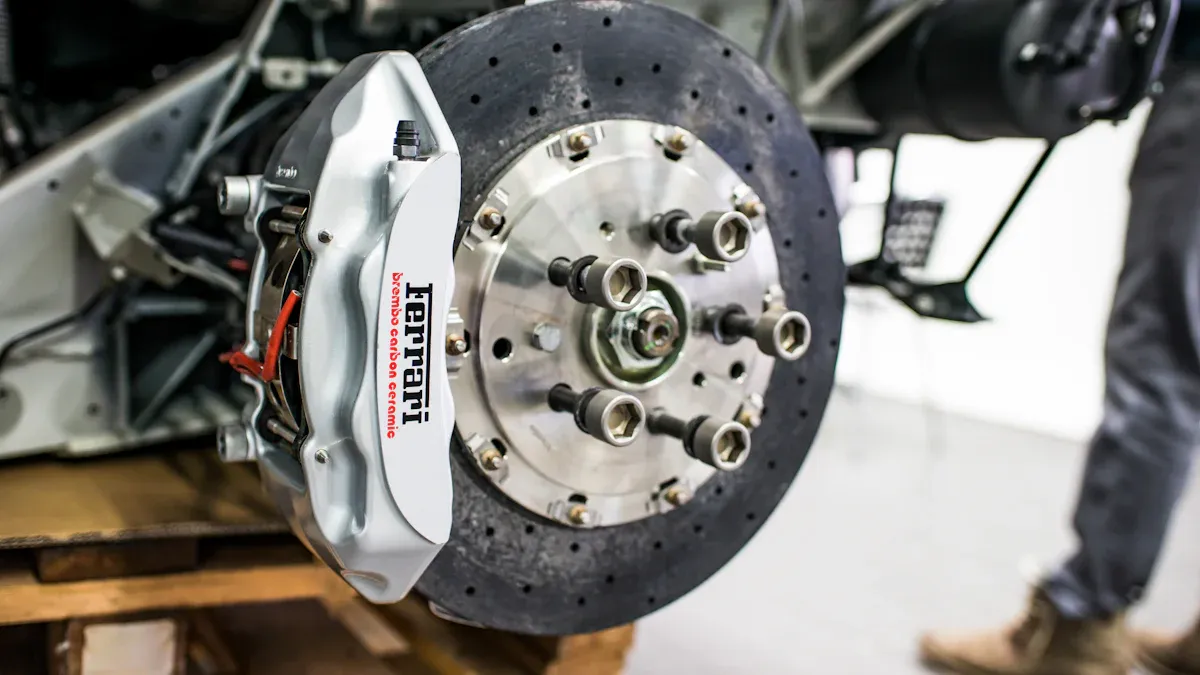

Kingham Technology is important in getting brake parts through OEM procurement. With over 15 years of experience, Kingham focuses on providing high-performance brake system parts. The company follows international quality rules to make sure its products meet the needs of everyday drivers and competitive racers.

Kingham shows its commitment to quality in how it makes parts. The company uses advanced CNC machines and strict quality checks to create reliable brake components. Also, Kingham’s focus on new ideas helps it keep up with market trends, especially as the car industry moves toward electric vehicles.

Different regions also affect OEM procurement practices. For example, the Americas focus on strict safety rules, while Europe pushes for new sensor technology. Kingham changes its strategies to meet these different market needs, making sure its brake parts stay competitive worldwide.

Key Quality Standards for Brake Components

ISO 9001 and IATF 16949

Quality standards are very important for making brake parts. They help make sure products are safe and work well. This is key for keeping vehicles safe. Two main standards in this area are ISO 9001 and IATF 16949.

ISO 9001 sets up rules for quality management systems. It focuses on having steady processes and happy customers. This standard is used in many industries, including cars, to ensure high-quality products.

IATF 16949 is based on ISO 9001 but is for the car industry. Its main goal is to keep improving, prevent problems, and cut down waste in the car supply chain. Important requirements include:

Choosing suppliers

Control Plans (CP) and second-party checks

Standardized Work (SW)

Total Productive Maintenance (TPM)

Managing products that do not meet standards

Kingham Technology follows these standards closely. The company has an ISO-certified factory that is 20,000 square meters big. It has three separate production lines, its own mold and anodizing shops, and over 100 CNC machines. Kingham checks quality with full inspections for every Motorcycle Suspension OEM project. This focus on quality helps Kingham win OEM contracts and keep a good name in the industry.

Compliance with Industry Standards

Brake parts must follow certain industry standards to be used for OEM. These standards include:

ISO 9001: A worldwide standard for quality management systems, ensuring steady processes and happy customers.

IATF 16949: The car industry’s quality management standard, combining ISO 9001 with special rules for cars.

Kingham shows it meets these standards with different tests. The company uses shock dyno curves, salt-spray test results, fatigue test data, and chosen road test results to check how well its brake parts work and last. This thorough way of checking quality makes sure Kingham’s products meet and go beyond industry standards.

By following these quality standards, Kingham makes its brake parts more reliable and safe. This focus on quality helps the company and also makes vehicles safer on the road.

Supply Chain Management Considerations

Supplier Selection and Compliance

Picking the right suppliers is key for OEM brake parts. Manufacturers must check suppliers to ensure they meet quality and performance needs. Here are important things to consider:

Product Quality and Standards: Suppliers need international certificates and must follow OEM rules. This makes sure parts are safe and work well.

Range of Products: Having many products makes sourcing easy and can save money.

Supplier Reliability & Delivery Timelines: Checking a supplier’s delivery skills helps prevent running out of stock.

Support and Warranty: Good customer service and warranties help fix problems after buying.

Cost vs. Value: Manufacturers should find suppliers with good parts at fair prices to get the best value.

Adherence to Industry Standards and Regulations: Following rules like ISO 9001 is important for keeping safety and quality.

Logistics and Shipping Capacity: A supplier’s skill in handling shipping is key for on-time delivery.

By focusing on these points, OEMs can create a strong supply chain that improves brake part quality.

Logistics and Timely Delivery

Logistics plans affect how fast brake parts get to OEMs. Good logistics make sure manufacturers get parts on time, reducing delays. Here are key strategies for better logistics:

Strategy | Description |

|---|---|

Proximity of Warehouses | Warehouses should be near OEM plants to cut delivery times. |

Optimized Warehouse Layout | A smart design saves space, important for big car parts. |

Sequencing of Parts | Parts must be ordered before delivery to stop delays. This needs skilled management. |

Compliance | Warehouses should have certificates (like ISO 9001) for proper part handling. |

Transportation | Using contract carriers is key for Just-in-Time (JIT) delivery needs. |

Besides these plans, using advanced warehouse systems can improve tracking and inventory. Using AI and data helps see and manage risks in logistics, so OEMs can quickly react to demand changes.

Kingham Technology shows great supply chain work by using these logistics plans. The company keeps good ties with suppliers, ensuring quality standards and on-time parts delivery. By using tech and improving logistics, Kingham boosts its buying process, leading to better product quality and happy customers.

Best Practices for Quality Maintenance

Quality Control Processes at Kingham

Kingham Technology uses strict quality checks to make sure its brake parts work well. These checks include:

Testing materials to see if they match design rules and standards.

Doing random checks with special tools to keep things accurate.

Checking how long parts last by testing them many times.

Following world quality rules like IATF 16949 and ISO 9001 to keep high standards.

These steps help Kingham make brake parts that are safe and make customers happy.

Continuous Improvement Strategies

Improving all the time is key in making things, especially brakes. Kingham uses many ways to keep getting better:

Workers learn easy ways to improve, like 5S, to make work smoother.

Small team events let workers solve problems together.

Quick weekly meetings let teams share ideas to fix problems fast.

A system tracks ideas and shows which ones work, helping new ideas grow.

Teams from different areas use reports to fix big problems, making sure they find good answers.

Bosses learn how to coach and solve problems to help teams do better.

These ways not only make making things better but also cut down on problems. By making sure brake parts are top quality, Kingham lowers mistakes and makes products more reliable.

Case Studies of Successful OEM Procurement

Example: Kingham’s Brake System Parts

Kingham Technology is a top company for getting brake parts. They work with many motorcycle makers to provide high-quality parts that follow strict OEM rules. For example, Kingham teamed up with a famous motorcycle brand to create a new type of brake caliper. This teamwork led to a product that improved braking and met the latest safety rules. This partnership shows how trust between manufacturers can lead to new ideas that help everyone.

Example: Collaboration with Major Brands

Kingham’s teamwork goes beyond single projects. The company has built strong partnerships with big names in the motorcycle world. These partnerships aim to create special brake parts that fit specific performance needs. For instance, Kingham worked with a leading brand to make a special brake pad for racing. This product was tested thoroughly to ensure it met OEM standards for strength and performance. The success of this collaboration shows how important trust and quality standards are for great results.

These case studies show that successful OEM procurement depends on strong partnerships and a focus on quality. Kingham’s ability to meet OEM standards while building trust with major brands shows its important role in the automotive supply chain.

Quality standards are very important in OEM procurement, especially for brake parts. Following these standards keeps things safe and makes the supply chain work better. Manufacturers gain from:

Certified compliance, which ensures products are made the same way and lowers risks.

On-time delivery, which is key for keeping production on track.

Careful checks that make sure parts last and work well.

By focusing on quality standards, manufacturers can build strong supplier relationships. This leads to more predictable deliveries and better production quality. In the end, focusing on safety standards not only makes products more reliable but also makes the whole supply chain stronger, helping the car industry succeed for a long time.

FAQ

What are the key guidelines for OEM procurement of brake components?

OEM guidelines make sure brake parts are safe and work well. These rules include following industry laws and quality standards. Manufacturers must stick to these guidelines to keep the parts real and dependable.

How does Kingham ensure compliance with industry standards?

Kingham follows strict rules to meet industry standards. The company uses advanced tests and quality checks to confirm that its brake parts are real and perform well, making sure they meet all needed standards.

Why is regulatory compliance important in OEM procurement?

Regulatory compliance makes sure brake parts are safe and work properly. It helps manufacturers avoid legal problems and keeps the parts genuine. Following these rules also makes the final product more reliable and safe.

How does Kingham verify the authenticity of its brake components?

Kingham uses careful testing and quality checks to confirm its brake parts are real. The company follows OEM guidelines and industry standards to ensure each part meets safety and performance needs.

What role do standards play in the supply chain compliance?

Standards make sure all parts in the supply chain are safe and meet quality needs. Following these standards helps keep the final product genuine and reliable, ensuring it meets all necessary rules and guidelines.