Honda Motorcycle Shock Absorber

Supplier – Platform-Based Wholesale Programs (Vario/PCX/Forza/ADV/CG)

- “Fast fitment confirmation by model-year + market (SEA/EU/LATAM)”

- “Warranty & claim-handling SOP for distributors and workshops”

- “Good/Better/Best ladder with stable replenishment rules”

- “Private label + packaging system for brand programs”

Built for Honda Distributors, Brands and Workshops

Honda scooter programs require careful planning—especially when balancing coverage, margin, and replenishment. Choose your role below and we’ll send you a recommended tiered assortment along with fitment confirmation for your market.

Distributors & Importers

Aftermarket & OEM Brands

Tuning Shops & Service Centers

Offer rebuildable solutions with clear adjustment guidance for customer setups.

Ready to see the data?

Honda Scooter & Commuter Platform Overview

Platform

Typical Role

Key Markets

Main Suspension Opportunities

Vario / Click

High-volume urban commuter

SEA, LATAM

Better control over bumps, stronger load support

PCX

Global commuter scooter

Global

Two-up comfort, long-distance stability

Forza

Premium GT scooter

EU, Asia

High-speed stability, premium appearance

ADV

Adventure-styled commuter

Asia, EU

Longer travel, mixed-surface stability

CG & Commuters

Utility / workhorse

Emerging markets

Heavy load support, durability, low life-cycle cost

Product Segmentation for Honda Partners

We’ve segmented Honda suspension solutions into three key tiers: "Essential (Good)", "Performance (Better)", and "Premium (Best)". Distributors can maximize margin and ensure reliable inventory with our tiered program structure.

Essential OE-Plus

- Stable Preload Support

- Commercial-Grade Durability

- Fitment Simplicity

- Optimized Bulk Packaging

Performance Adjustable

- Precision Rebound Tuning

- Gas-Charged Valving Tech

- Professional Tuning Guidance

- Shop-Friendly SKU Planning

Premium / GT Line

- Rebound + Compression Control

- Full CNC Machined Finish

- Stronger End-Stroke Support

- Rebuildable High-Spec Build

Core Suspension Series for Honda

Forza Q054

Vario Q058

Giorno H187B

Honda Vario / Click Suspension Program — Volume Coverage + Fast Reorder

The Limits of Stock Suspension

- Unresponsive Handling: Basic damping struggles to manage rapid weight shifts and frequent road surface changes, leading to slow reaction times and instability in dense traffic.

- Harsh Impacts: Simplistic stock springs fail to absorb sharp bumps and small obstacles, transferring unnecessary shock and fatigue to the rider.

Kingham Tech Engineering Advantage

- Refined Valving Protocol: High-precision internal valving stack optimized for quick recovery and superior stability required in constant stop-and-go urban environments.

- High-Flow Damper Rod Kit (Front): Front fork upgrades utilize advanced hydraulic control to improve steering precision and eliminate front-end bounce and dive.

Q012

Q078

Q058

Q065

H154

H154B

H154C

H171

H135

Honda PCX Suspension Program — Two-Up Comfort + Long-Distance Stability

Performance Deficiencies of Stock Unit

- Stock pain: heat fade on long rides + unstable feel under two-up riding, leading to “upgrade not obvious” feedback.

- Business pain: shops need baseline tuning guidance; distributors need a clear step-up story from Essential → Performance to protect margin.

Kingham Tech Engineering Advantage

- Engineering advantage: monotube oil volume + thermal stability to keep damping consistent during longer distance use.

- Engineering advantage: baseline tuning sheet (clicks/preload guideline) included for workshops to standardize installation and reduce aftersales disputes.

Q047

H150

H150

H171

H117

H00A

JH008

JH002

H003

Honda Forza Suspension Program — Premium GT Feel + High-Speed Stability

The Limits of Stock Suspension

- Stock pain: high-speed float + sharp-edge harshness, especially when riders expect “GT premium feel”.

- Business pain: premium buyers judge appearance and finishing—poor surface/branding consistency hurts distributor positioning.

Kingham Tech Engineering Advantage

- Engineering advantage: premium GT build spec (CNC finish + hard anodizing + consistent cosmetics) designed for higher price acceptance.

- Engineering advantage: high/low-speed damping control aimed at GT stability + comfort, with validation screenshots available in spec pack.

Q054

H117

H012

H033

H102

Honda ADV Suspension Program — Travel, Support and Thermal Stability

Performance Deficiencies of Stock Unit

- Stock pain: frequent bottoming on potholes + unstable rebound on rough city roads, not only “off-road”.

- Business pain: mixed-use customers complain unpredictably; partners need a “one-setup-fits-most” tuning baseline to reduce returns.

Kingham Tech Engineering Advantage

- Engineering advantage: longer-travel support + stronger end-stroke control for pothole-heavy roads and mixed surfaces.

- Engineering advantage: optional reservoir / higher thermal capacity to keep damping stable for longer rides and hot climates.

H152

Honda CG Suspension Program — Heavy Load Durability + Low Life-Cycle Cost

The Limits of Stock Suspension

- Stock pain: seal wear + shaft bending risk under continuous load, leading to early leakage and replacements.

- Business pain: distributors get dragged into claim disputes—what they need is predictable durability + spare parts logic.

Kingham Tech Engineering Advantage

- Engineering advantage: reinforced shaft/seal package + load-oriented spring options to extend service life.

- Engineering advantage: warranty & spare parts policy (seal kit / bushing / hardware) offered as part of distributor program to protect reputation.

H012

H133

H179

H180

H001

Honda Scooter Starter Program

- Coverage: 5 core platforms (Vario, PCX, Forza, ADV, CG).

- SKU Count: 8-10 core SKUs across Essential / Performance / Premium

- Business Focus: Fast turnover + margin protection

Your Expert Partner in Suspension Manufacturing

Design & R&D

Our experienced R&D team, with over 15 years of industry expertise, develops more than 20 new products annually for our clients. Leveraging over 70 technical patents, we collaborate with customers to ensure their brands maintain sustained competitiveness in the market.

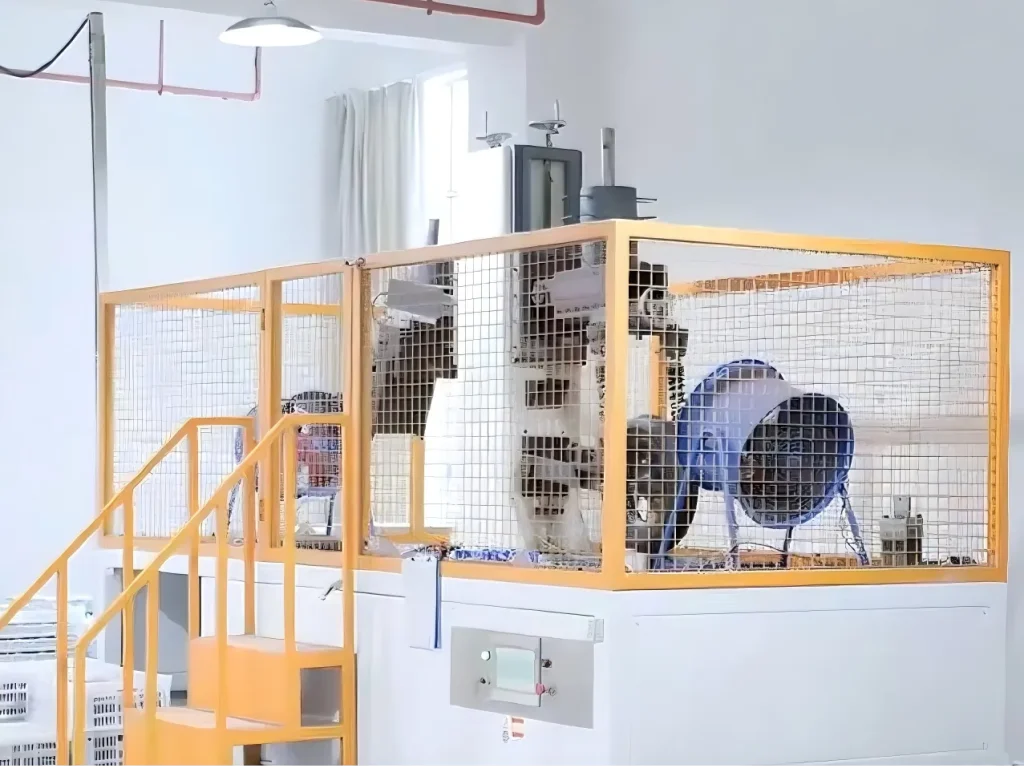

Advanced Manufacturing

Our modern manufacturing facility spans over 16,000 square meters, equipped with more than 90 CNC precision machines and a dedicated anodizing workshop. We utilize automated assembly and testing equipment while implementing comprehensive quality inspections to ensure every product meets the highest standards.

Global Partnership

With over 7 years of ODM/OEM service experience, we have successfully served aftermarket clients across Europe, the United States, and Southeast Asia. We provide comprehensive customization services, committed to becoming your most trusted suspension system solutions provider.

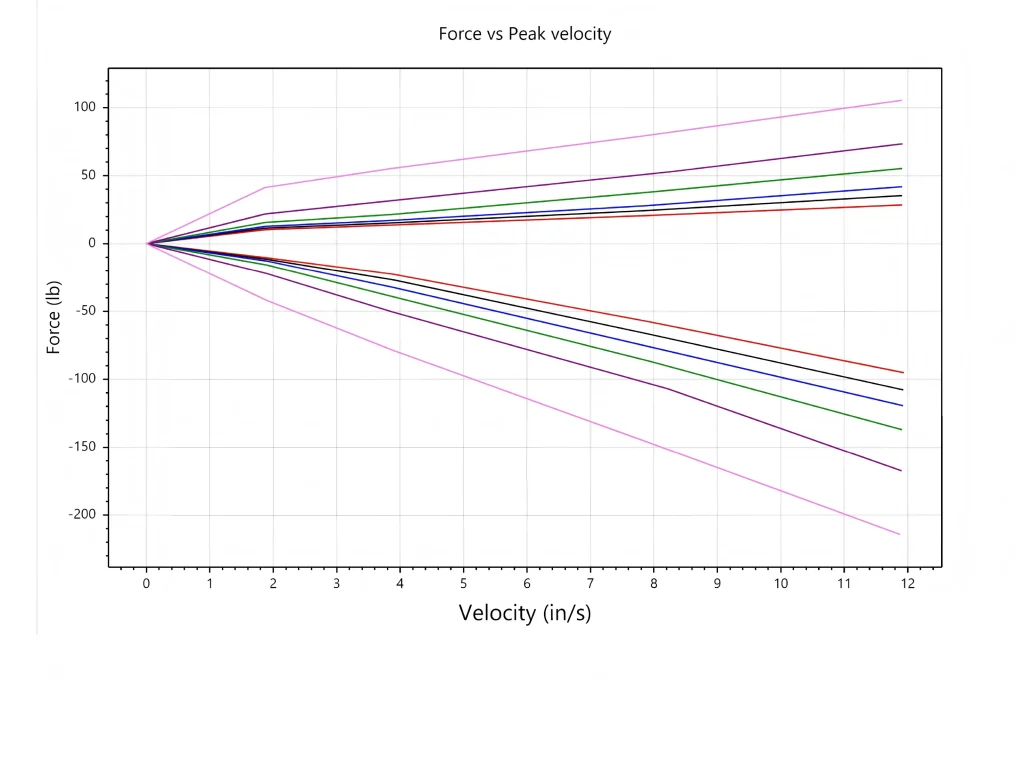

Performance Validation & Reliability Metrics

Quantified Damping Performance

Structural Reliability

Testing

Production Quality & Consistency

Component & Environmental Verification