Harley-Davidson Rear Shocks

Manufacturer & OEM/Wholesale Suspension Supplier

- IATF 16949 & ISO 9001 certified processes ensure consistent quality

- In-house CNC machining + anodizing control for premium finish

- Built for "Touring", "Dyna", "Sportster", and "Custom Programs"

- OEM/ODM-ready engineering & validation.

Built for Harley Distributors, Brands and Workshops

Distributors & Importers

Aftermarket & OEM Brands

Tuning Shops & Service Centers

Ready to see the data?

Harley Platform Overview — What to Stock First

Platform

Typical Role

Key Markets

Main Suspension Opportunities

Touring (Bagger)

Long-distance, two-up & luggage cruising

US, EU, AU

Load support, heat/fade control, comfort over expansion joints, stability at highway speeds

Dyna

Power cruiser + aggressive street riding

US, EU

Rear support under acceleration, cornering control, stance + performance upsell

Sportster

Urban agility + custom builds

US, EU, JP

Low-profile comfort, controlled damping on short travel, custom stance compatibility

Product Segmentation for Harley Partners

We’ve segmented Harley suspension solutions into three key tiers: "Essential (Good)", "Performance (Better)", and "Premium (Best)". Distributors can maximize margin and ensure reliable inventory with our tiered program structure.

Essential OE-Plus

- Who it’s for: distributors entering Harley + workshops needing fast install SKUs

- Stock first: 4–6 core movers (standard lengths + most common finishes)

- How it makes money: How it makes money: fastest turnover + lowest claim risk

Performance Adjustable

- Who it’s for: club-style / performance cruiser shops and premium dealers

- Stock first: Dyna performance movers + 1–2 Touring upsell SKUs

- How it makes money: margin pickup via “stance + control” upsell story

Premium Touring Load-Control

- Who it’s for: bagger/touring dealers focused on two-up + luggage riders

- Stock first: flagship load-control SKUs + spare-parts policy clarified

- How it makes money: higher ASP + fewer comfort complaints → strong repeat orders

Core Suspension Picks for Harley Programs

H148

H172

H149

H01201

Suspension Upgrades for Harley Davidson Touring Family

Engineered for the long-distance haul. These iconic models demand exceptional load management and comfort to support two-up riding and fully-laden luggage over extended trips.

The Limits of Stock Suspension

- Load Management Failure: Factory suspension struggles with two-up riding and luggage, leading to frequent bottoming-out and unpredictable handling over highway undulations.

- Ride Harshness: Lack of refined compression damping translates into sharp jolts and discomfort when encountering square-edged bumps and expansion joints.

Kingham Tech Engineering Advantage

- Hydraulic Preload Adjustability: Integrating a hydraulic system for quick, tool-free adjustment of sag, ensuring optimal ride height is maintained regardless of passenger or luggage weight.

- Nitrogen-Charged Monotube Design: Utilizing a single-tube design with nitrogen charge for superior heat dissipation and consistent, fade-free damping throughout long-distance cruising.

H149

H148

H01201 BLACK

Performance Solutions for Harley Davidson Dyna

Engineered for power and aggressive riding. Celebrated for its powerful engine, unique handling, and strong presence in the custom bike scene, the platform demands stability for high-speed riding.

Performance Deficiencies of Stock Unit

High-Speed Instability: The frame and stock suspension struggle with the engine’s power output at speed, causing excessive wobble, especially in sweeping corners.

Limited Cornering Capability: Restricted ground clearance and poor rebound control limit lean angle, forcing riders to reduce speed significantly through turns.

Kingham Tech Engineering Advantage

Performance Monotube Shocks (Rear): High-end monotube design with adjustable rebound and compression to deliver aggressive cornering capability and precise chassis control.

Increased Ground Clearance: Specific shock lengths are available to raise the ride height, maximizing lean angle potential and preventing scraping under spirited riding.

H149

H01201 BLACK

Suspension Upgrades for Harley Davidson Sportster

Engineered for agility and urban performance. This lightweight, versatile model is the perfect foundation for custom builds, demanding suspension that sharpens cornering precision and provides a more controlled, planted feel.

The Limits of Stock Suspension

Harsh Ride & Low Travel: Stock units often have limited travel and simplistic damping, resulting in a harsh, uncomfortable ride that struggles with everyday road imperfections.

Cornering Imprecision: The lack of refined damping control causes excessive chassis movement, leading to vague steering input and reduced confidence when leaned over.

Kingham Tech Engineering Advantage

Enhanced Damping Rod Kit (Front): Front suspension upgrades utilize superior valving technology to improve hydraulic control, eliminating front-end bounce and dive without sacrificing comfort.

Progressive Rate Springs (Rear): Rear springs are engineered with a progressive rate curve to improve small bump absorption while maintaining the low-profile stance desired by custom builders.

H149

H01201 BLACK

Harley Distributor Starter Program

- Coverage: Touring + Dyna + Sportster.

- SKU Count:8-10 core SKUs across Essential / Performance / Premium.

- Business Focus:Fast turnover + margin protection

Your Expert Partner in Suspension Manufacturing

Design & R&D

Our experienced R&D team, with over 15 years of industry expertise, develops more than 20 new products annually for our clients. Leveraging over 70 technical patents, we collaborate with customers to ensure their brands maintain sustained competitiveness in the market.

Advanced Manufacturing

Our modern manufacturing facility spans over 16,000 square meters, equipped with more than 90 CNC precision machines and a dedicated anodizing workshop. We utilize automated assembly and testing equipment while implementing comprehensive quality inspections to ensure every product meets the highest standards.

Global Partnership

With over 7 years of ODM/OEM service experience, we have successfully served aftermarket clients across Europe, the United States, and Southeast Asia. We provide comprehensive customization services, committed to becoming your most trusted suspension system solutions provider.

Performance Validation & Reliability Metrics

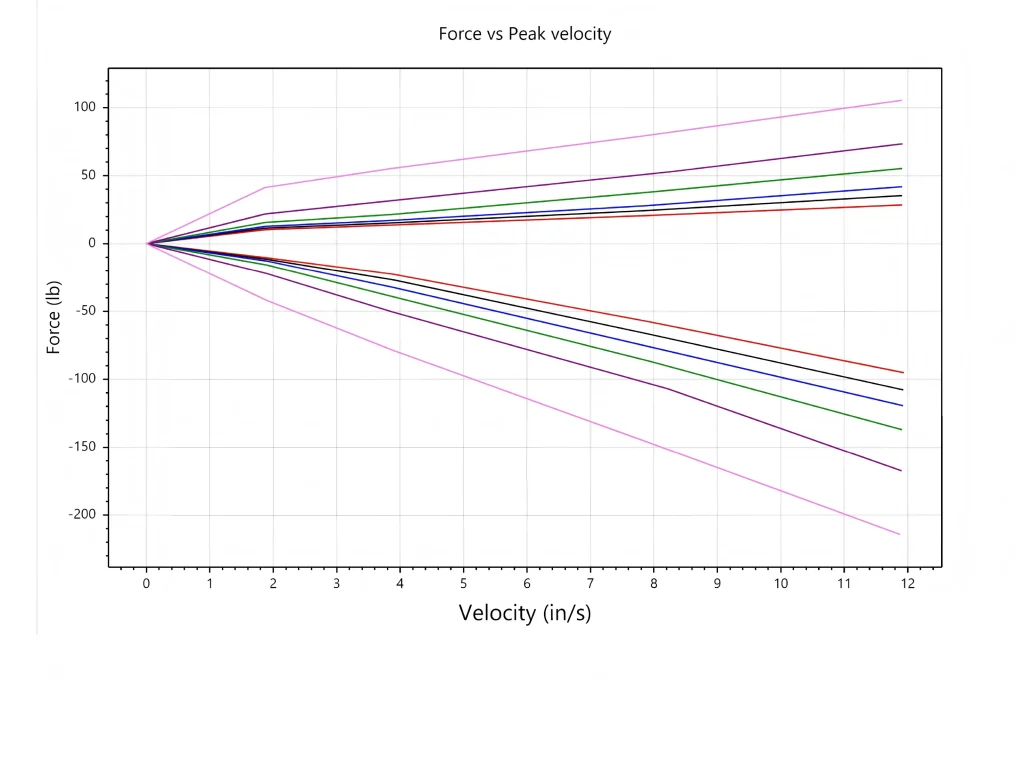

Quantified Damping Performance

This Force vs Velocity curve is the definitive proof of our performance. It confirms that our damping system maintains predictable force output and consistency, ensuring balanced and superior handling across all operating speeds.

Structural Reliability

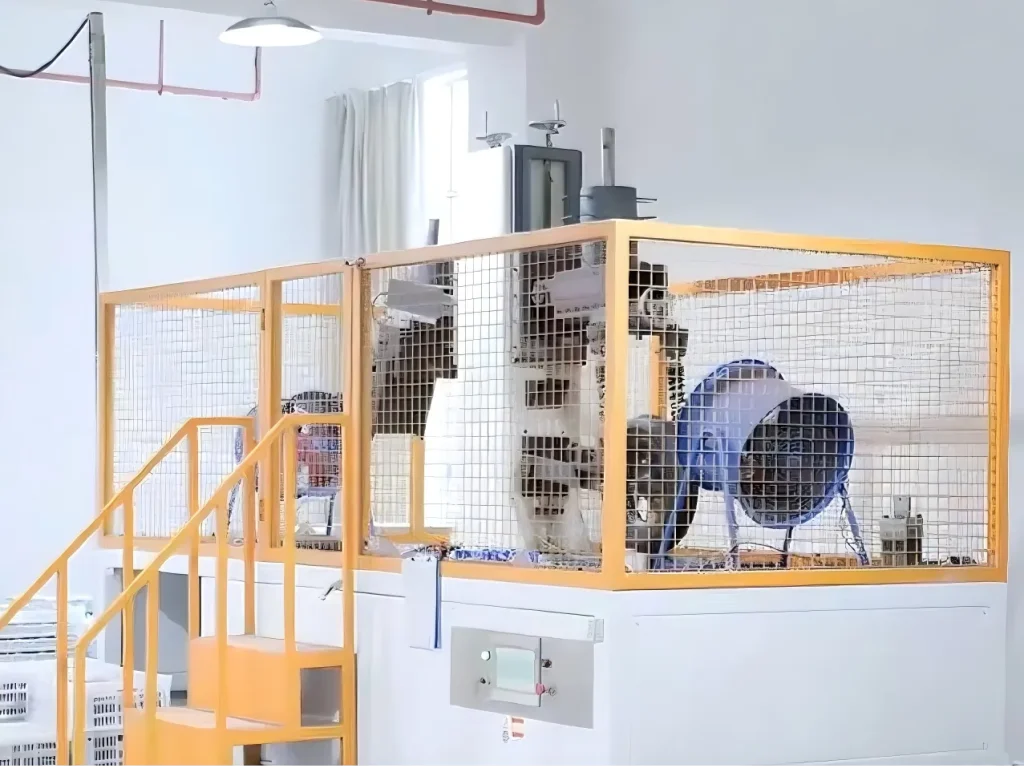

Testing

Critical components undergo rigorous fatigue testing on specialized equipment. This protocol validates the structural integrity of our components, providing partners with confidence in the long-term durability and warranty commitment.

Production Quality & Consistency

Every unit undergoes high-speed dyno validation to verify precision before packaging. This quality control step guarantees that all production batches meet the same high standard of control and stability.

Component & Environmental Verification

We confirm material integrity and component precision using dedicated inspection equipment. All external alloys are tested for superior corrosion resistance, confirming their durability in diverse global environments.

FAQ

Can we mix multiple platforms in one order?

Do you offer private label packaging?

What is the lead time for Harley suspension orders?

Can we adjust the damping settings?

Get a Harley Suspension Proposal

Share details about your Harley platforms. Usually reply within 1–2 days.